A kind of vinyl polar monomer implements the method for anionic addition polymerization

A technology of anionic polymerization and polar monomers, which is applied in the field of anionic addition polymerization of vinyl polar monomers, can solve the problem that the stability needs to be further improved, and can enrich the varieties of high-performance polymers and suppress side reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

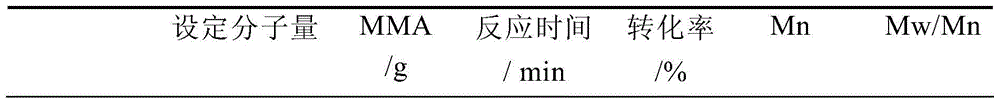

[0033] Example 1: Preparation of polymethyl methacrylate (PMMA)

[0034] At 20°C, under the premise that the water in all reagents is less than 10ppm, add 48ml of THF to the reaction kettle, add 0.001mol of 0.1M n-butyllithium (n-BuLi), and then add 0.198g of DPE to react for 10min. Then add 2.24g (0.02mol) potassium tert-butoxide (t-BuOK), react for 10min, then add 10g MMA monomer and stir evenly, and the designed molecular weight is 10,000. After 20 min of reaction, the polymer active species were terminated with 1 ml of methanol. The conversion rate is shown in Table 1, the molecular weight of the product and its distribution are determined by GPC, and the results are shown in Table 1.

Embodiment 2

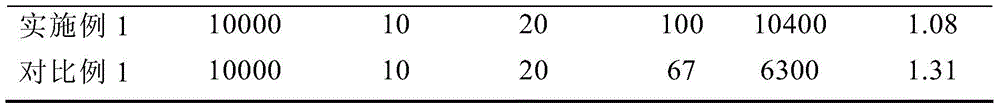

[0041] Example 2: Polymerization of polystyrene-polybutadiene-polymethylmethacrylate triblock polymerization (PS-b-PB-b-PMMA)

[0042] At 50°C, under the premise that the water in all reagents is less than 10ppm, add 48ml toluene to the reaction kettle under the protection of 0.4MPa high-purity argon, add 0.1M tert-butyllithium (t-BuLi) 0.00025mol, styrene (St) 1.25g (design molecular weight 5000), after 10min of polymerization, add 7.5g of butadiene (Bd) (design molecular weight 30000), and polymerize for 20min. The system was cooled to 10° C., 0.66 g (0.005 mol) of potassium phenate was added, stirred uniformly, and reacted for 10 min. Add MMA 2.5g, about 2.65ml, the designed molecular weight is 10000. The reaction was carried out for 20 minutes. After the reaction was completed, the polymer active species was terminated with 1 ml of methanol. The conversion rate is shown in Table 2, the molecular weight of the product and its distribution are determined by GPC, and the r...

Embodiment 3

[0048] Example 3: Polymerization of polymethyl methacrylate and tert-butyl methacrylate diblock copolymer [P(t-BMA)-b-PMMA]

[0049] Under the premise that the water in all reagents is less than 6ppm at 60°C, add 60ml of THF to the reaction kettle, add 0.1M n-BuLi 0.0005mol, DPE 0.1g (0.00055mol), stir evenly, and react for 10min. Add 1.82 g (0.01 mol) of potassium naphthol, stir evenly, and react for 10 min. 7.5 g of tert-butyl methacrylate (t-BMA) was added, and the designed molecular weight was 15,000. After 10min of polymerization, 4g of MMA was added, and the designed molecular weight was 8000, and the reaction was carried out for 20min. After the reaction, the active species of the polymer were terminated with 1 ml of methanol. The conversion rate is shown in Table 3, the molecular weight of the product and its distribution are determined by GPC, and the results are shown in Table 3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap