Buried micro composite pile group and its anti-sliding design method

A design method and technology of micro piles, applied in excavation, construction, infrastructure engineering and other directions, can solve problems such as ineffectiveness and waste, avoid cost waste, reduce project cost, and ensure the effect of prevention and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

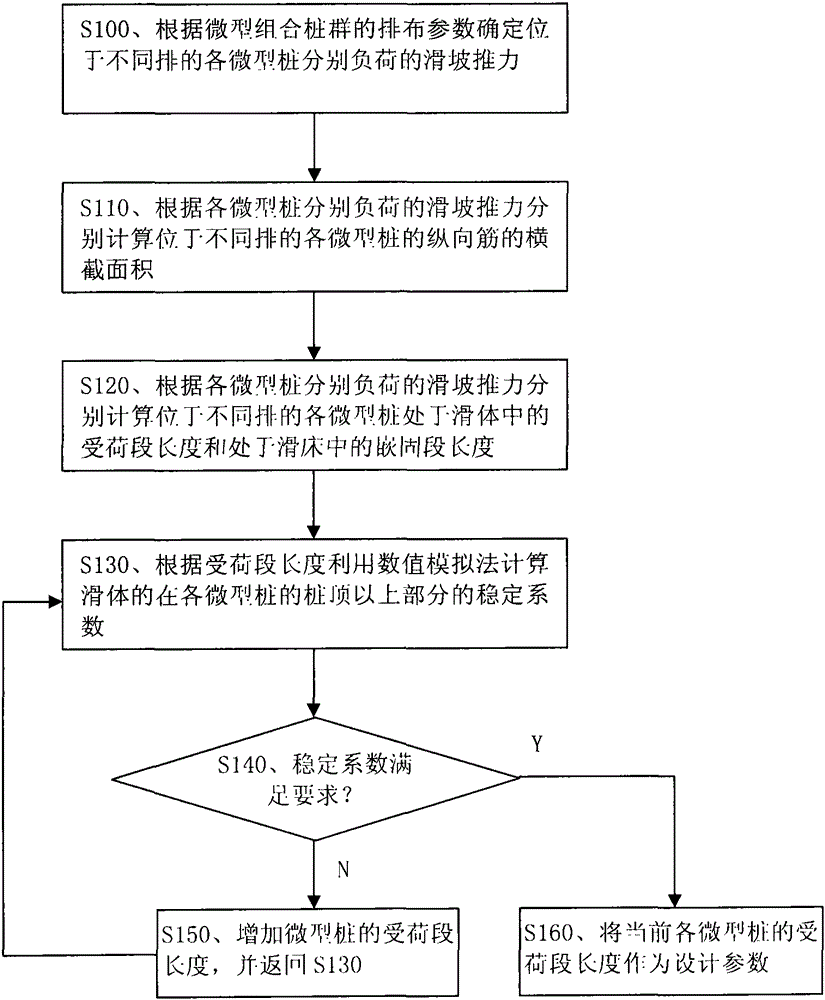

[0027] Embodiment 1. Anti-sliding design method of embedded micro-composite pile group. The procedure of this method is as follows figure 1 shown.

[0028] figure 1 Among them, S100, according to the arrangement parameters of the micro-combined pile group, determine the landslide thrusts of the respective loads of the micro-pile located in different rows.

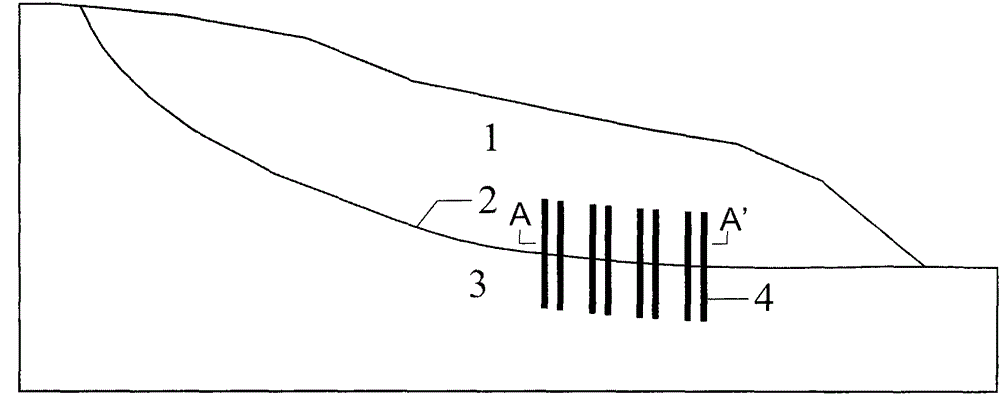

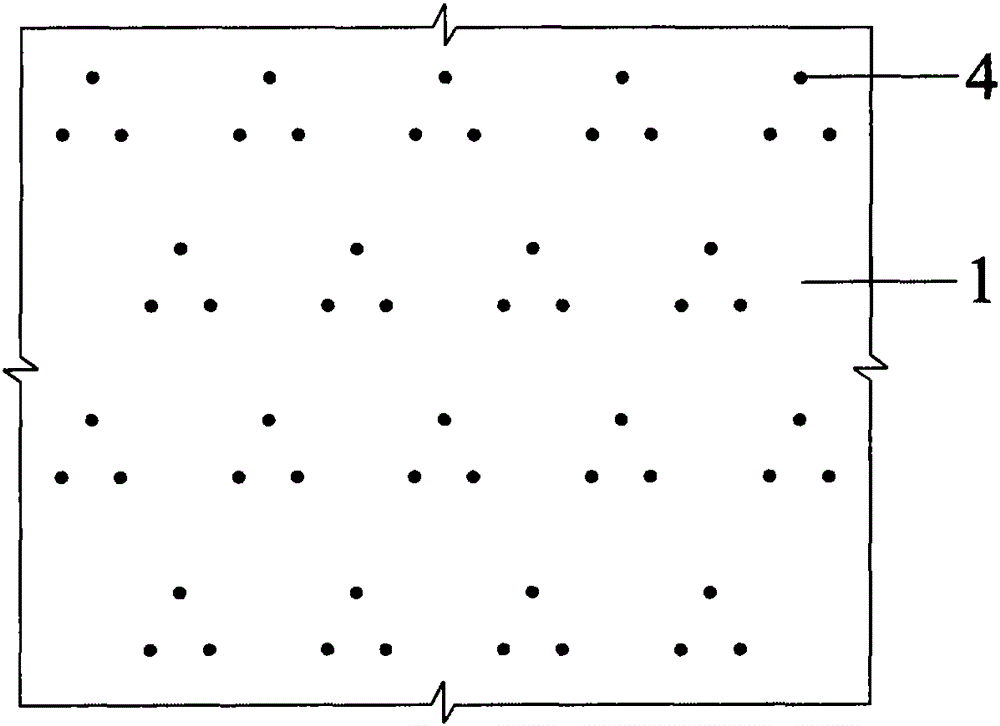

[0029] Specifically, the micro-combined pile group in this embodiment is an embedded micro-combined pile group, that is, the micro-combined pile group is arranged in the landslide by embedding, such as figure 2 As shown, a part of the micropile 4 is embedded and fixed in the sliding bed 3 to form an embedding section, while the other part of the micropile 4 is located in the sliding body 1 above the sliding belt 2 to form a load-bearing section, that is, the present embodiment The micro-pile 4 is composed of an embedding section and a load-bearing section, and there is a certain distance between the pile top of each mic...

Embodiment 2

[0063] Embodiment two, buried type miniature combined pile group.

[0064] The embedded micro-combined pile group of this embodiment is at least composed of two rows and two rows of micro-pile, and each micro-pile is composed of a load-bearing segment and an embedded segment; wherein, the length of the load-bearing segment of each micro-pile should be the above-mentioned Determined by the method described in S100-S150 in Embodiment 1. In addition, in this embodiment, the length of the embedding section of each micro-pile can be determined according to the formula (3) in the first embodiment above, and the cross-section of the longitudinal reinforcement of each micro-pile can be determined according to the formula (1) in the first embodiment above. area. For the determination of the length of the load-bearing section of each micro-pile, the determination of the length of the embedded section of each micro-pile, and the determination of the cross-sectional area of the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com