Frictional energy dissipation type buckling-restrained brace

A technology of anti-buckling support and frictional energy consumption, which is applied in the direction of earthquake resistance and building components, can solve the problem of single energy consumption form, and achieve the effect of improving energy consumption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

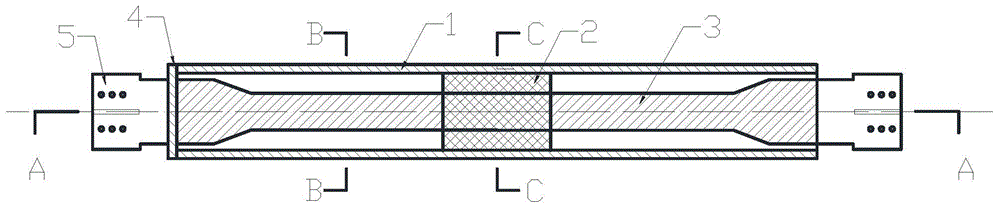

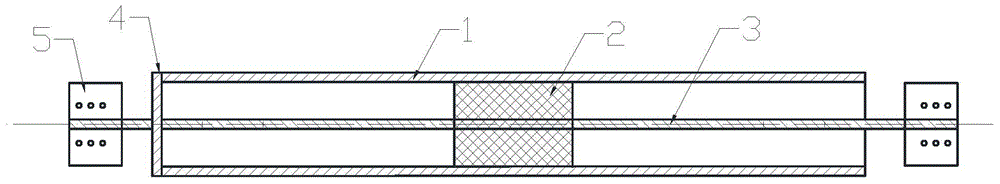

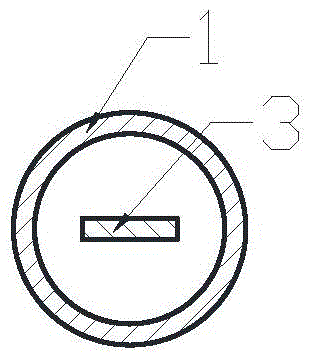

[0020] Such as figure 1 The frictional energy-dissipating anti-buckling support shown includes a constraining member 1, a piston 2, and an energy-dissipating core material 3; 1 is fixed to one end of the energy-dissipating core material 3 through the end plate 4; connecting steel plates 5 are provided at both ends of the energy-dissipating core material 3. The cross-section of the constraining member 1 is square, and the energy-dissipating core material 3 is a straight steel plate weakened in the middle, such as Figure 3b , 4b shown.

[0021] The quantity of described piston 2 is one or more, such as figure 1 , Figure 5 shown; the cross-sectional form of the piston 2 is consistent with the partial form enclosed by the cross-section of the constraining member 1, such as Figure 4b shown.

[0022] When the interlayer displacement occurs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com