Method for manufacturing archaistic reinforced floor board

A technology for strengthening floors and floors, applied in chemical instruments and methods, building structures, laminating devices, etc., can solve the problems of poor surface flatness of substrates, insignificant antique effect, and long time consumption, and achieve accurate embossing. , good antique effect, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the following method is used to manufacture antique laminate flooring:

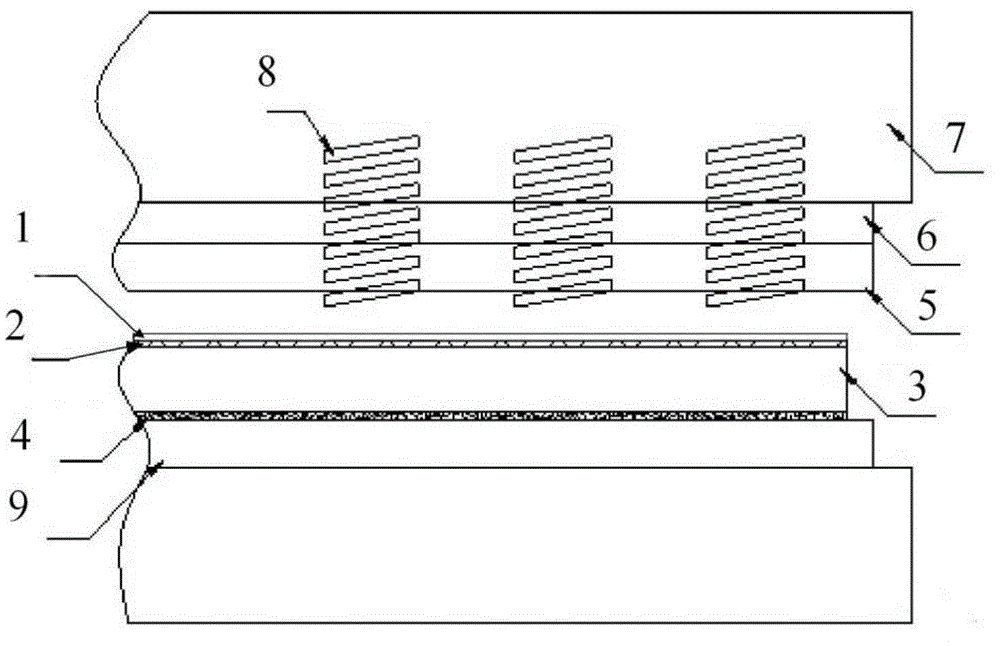

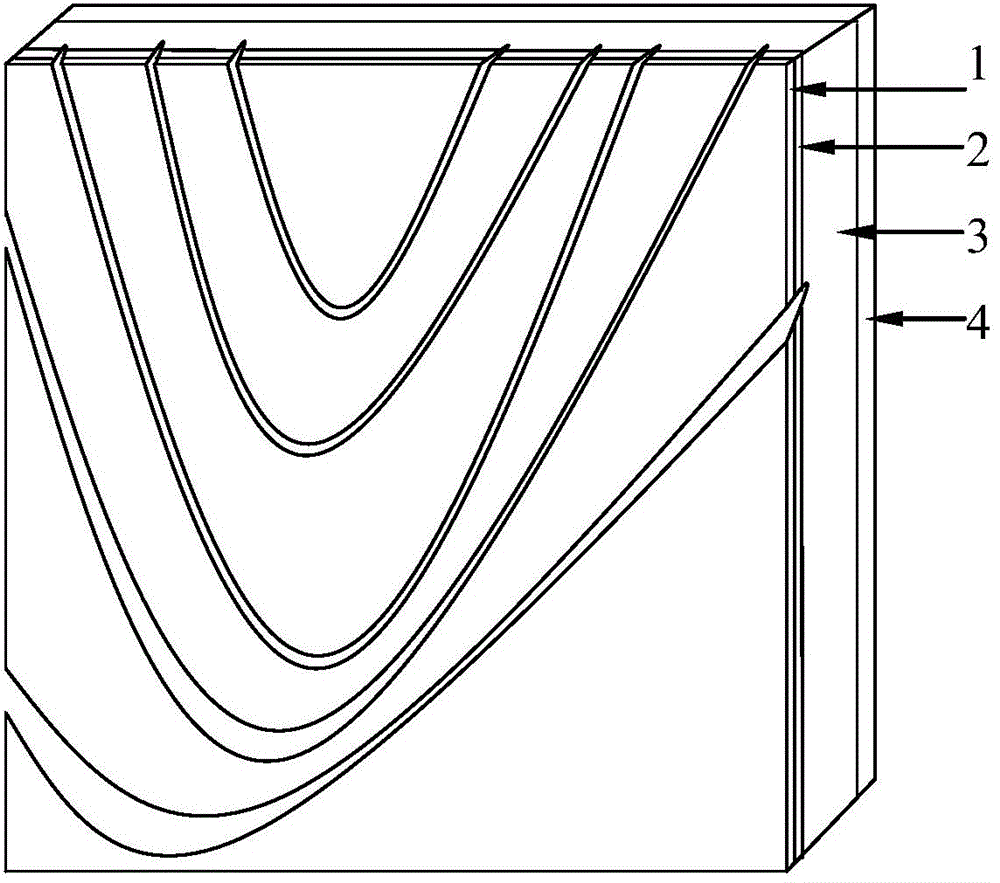

[0028] (1) if figure 1 with figure 2 As shown, a wear-resistant layer 1, a decorative layer 2, a base material 3 and a balancing layer 4 for making antique laminate flooring are provided, wherein the upper surface of the decorative layer 2 has a wood grain texture, and the balancing layer 4 is a modified balancing paper , consisting of pulp with a volume percentage of 70%, rutile titanium dioxide with a volume percentage of 25%, wood pulp with a volume percentage of 2.5%, waste paper with a volume percentage of 1% and volume percentage Consists of 1.5% nanocrystalline cellulose with a density of 0.6g / cm 3 , the smoothness is 7S, the dry tensile force is 30N, the wet tensile force is 41N, the ash content is 19%, and the moisture content is 5%. When the temperature is below this temperature, it is in a solidified state. The rutile type titanium dioxide and nano-crystalline fib...

Embodiment 2

[0034] The method of this embodiment is roughly the same as the method of embodiment 1, the difference is that: the pattern on the upper surface of the decorative layer and the working surface of the upper molded steel plate is a stone grain texture, and the balance layer used is made of pulp with a volume percentage of 68%. , rutile titanium dioxide with a volume percentage of 30% and nanocrystalline cellulose with a volume percentage of 2%, with a density of 0.6g / cm 3 , the smoothness is 13S, the dry tensile force is 35N, the wet tensile force is 43N, the ash content is 24%, and the moisture content is 7%; The patterns on the working surfaces of the upper and lower molded steel plates are star-shaped, with a convex height of 0.1 mm, an indentation depth of 0.3 mm on the upper surface of the substrate, and a 0.6 mm indentation depth on the upper surface of the floor.

Embodiment 3

[0036] The method of this embodiment is roughly the same as that of Example 1, the difference being that the balance layer adopted is composed of wood pulp with a volume percentage of 73%, rutile titanium dioxide with a volume percentage of 20%, and a volume percentage of 20%. Composed of 3% wood pulp and 4% volume percent nanocrystalline cellulose, with a density of 0.6g / cm 3 , the smoothness is 20S, the dry tensile force is 40N, the wet tensile force is 50N, the ash content is 22%, and the moisture content is 6%; On the spring between the table and the upper molded steel plate, the pattern convex height of the working surface of the lower molded steel plate is 0.12mm, the indentation depth on the upper surface of the substrate is 0.2mm, and the indentation depth on the upper surface of the floor is 0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com