Continuous automatic feeding and discharging embossing machine and production process thereof

A technology of automatic loading and unloading, production process, applied in the direction of machining/deformation, etc., can solve the problems of conveying efficiency, embossing efficiency and embossing quality improvement, embossing raw materials inclined embossing, adhesion dust and other problems, to achieve the printing effect Good, improve the embossing efficiency, the effect of large operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Preliminary preparation: conduct a comprehensive and detailed inspection of all equipment to confirm that there is no abnormality in the equipment;

[0054] (2) Making an embossing template: the embossing template is a screen printing template, and the screen printing template includes a bottom plate d, an embossing negative film c, a screen b, and a photosensitive adhesive layer a from the inside to the outside, wherein, in the darkroom, The photosensitive adhesive layer is scraped onto the screen with a scraper, scraped twice on the scraped surface of the screen, and dried naturally. The hardness of the scraper is 70 degrees Shore, and the screen is made of polyester Screen, the mesh number of the screen is 300, and the tension of the screen is 15N / cm2;

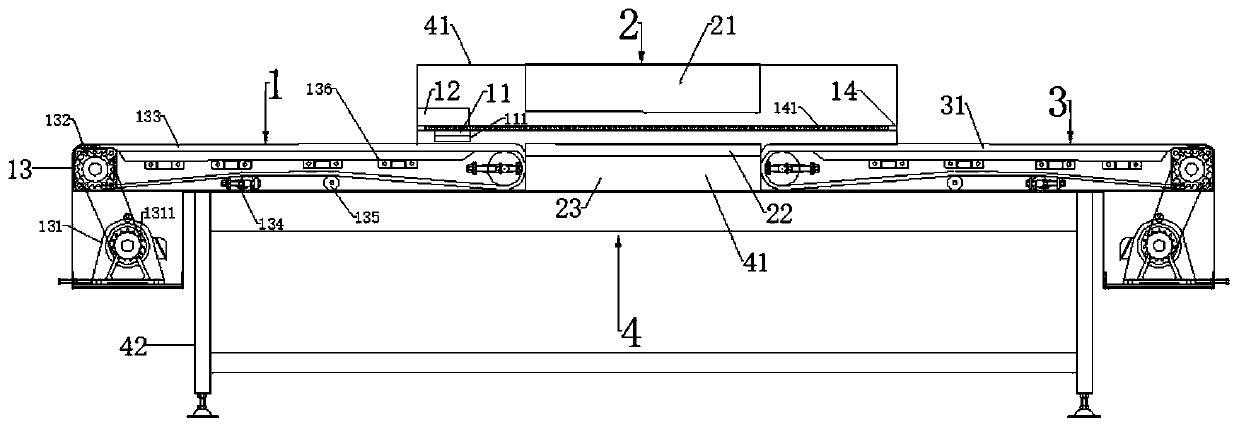

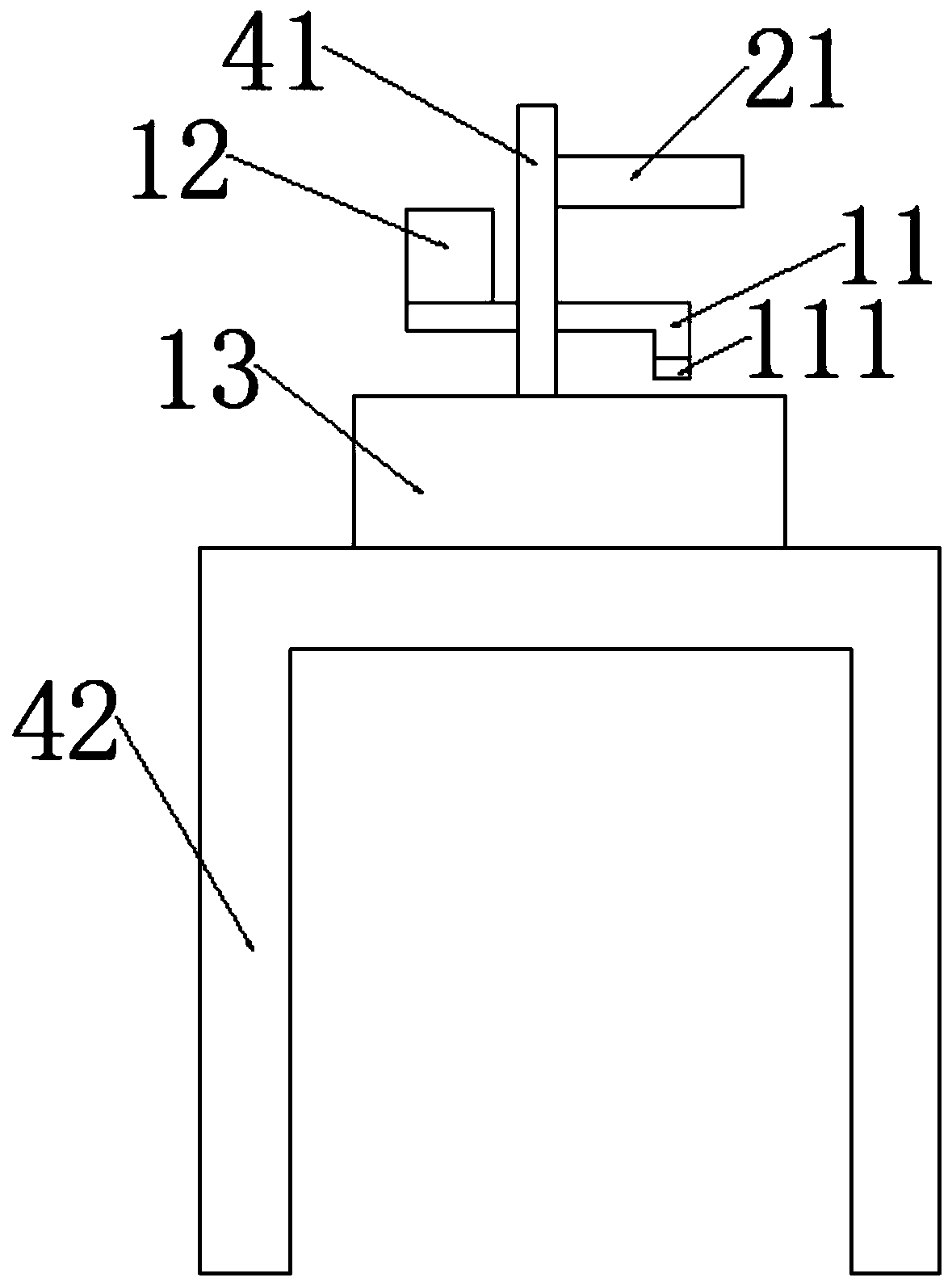

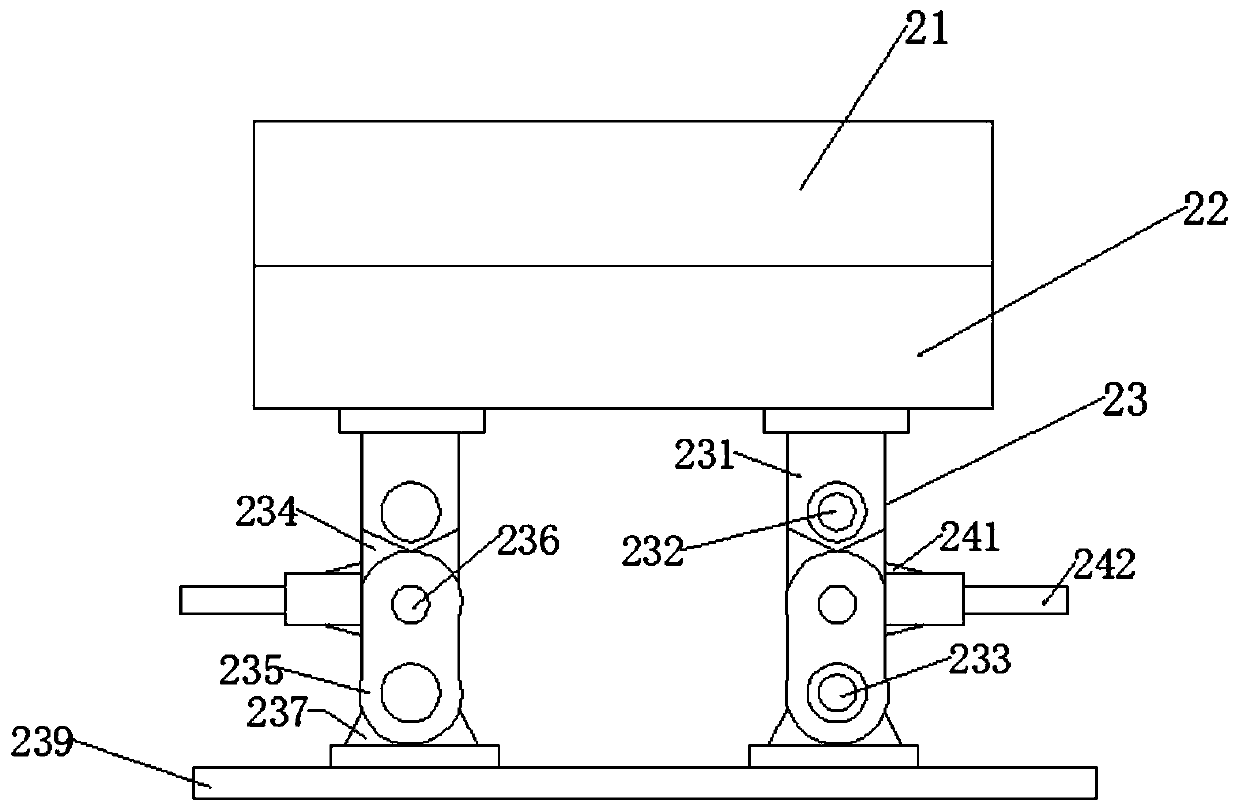

[0055] (3) Embossing: Place the paper to be embossed on the transmission chain 133 of the conveying mechanism 13 of the paper feeding mechanism 1, and then automatically feed the paper. When the paper is conveyed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com