Panel embossing processing device

A processing device and plate technology, which is applied in the field of plate processing, can solve the problems of poor visual three-dimensional effect on walls and floors, lack of natural material realism, etc., and achieve the effect of strong three-dimensional effect, high dimensional stability and continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Exemplary embodiments of the present invention are described below with reference to the accompanying drawings. It should be understood that these specific descriptions are only used to teach those skilled in the art how to implement the present invention, and are not intended to exhaust all feasible modes of the present invention, nor are they used to limit the protection scope of the present invention.

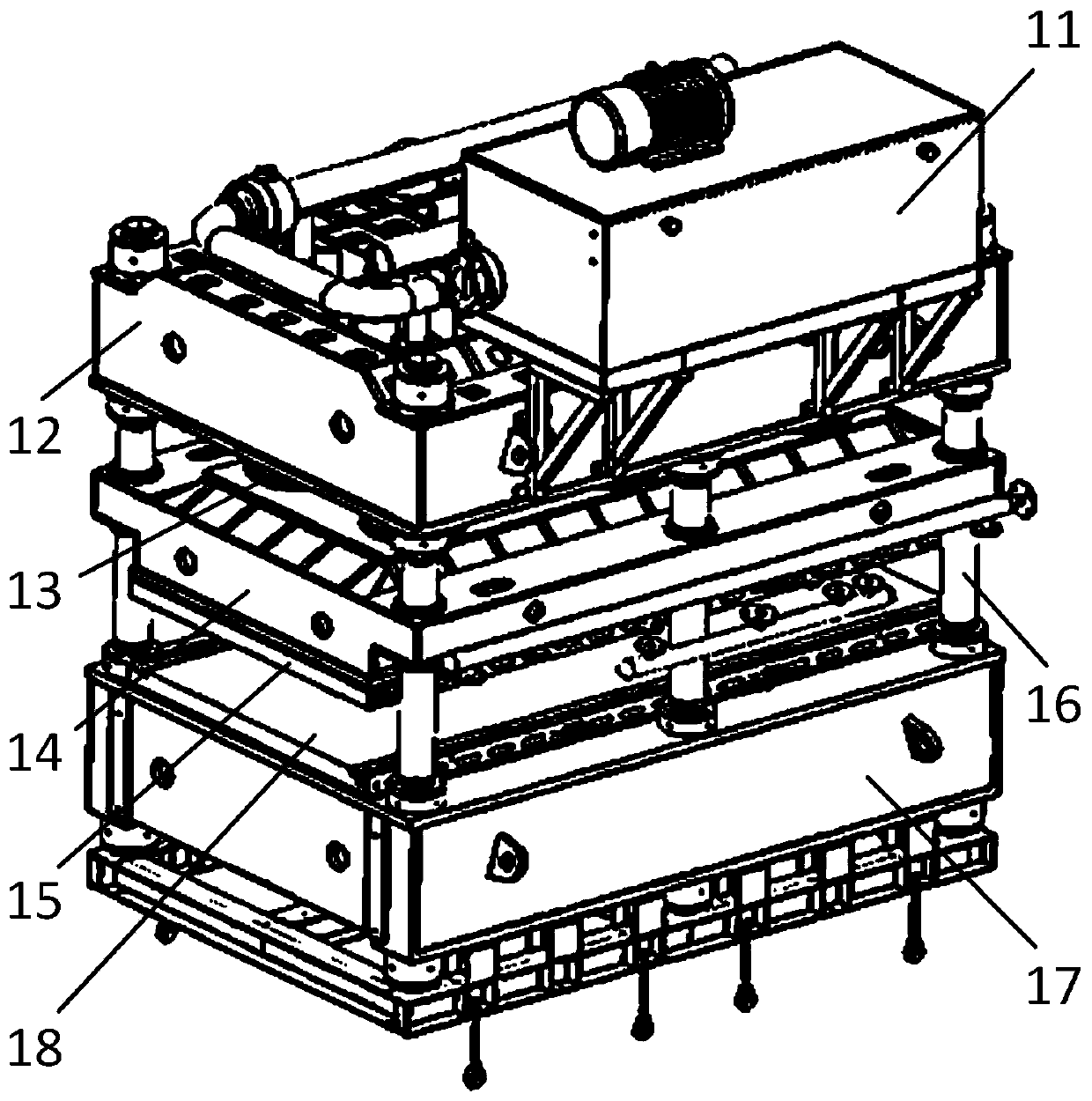

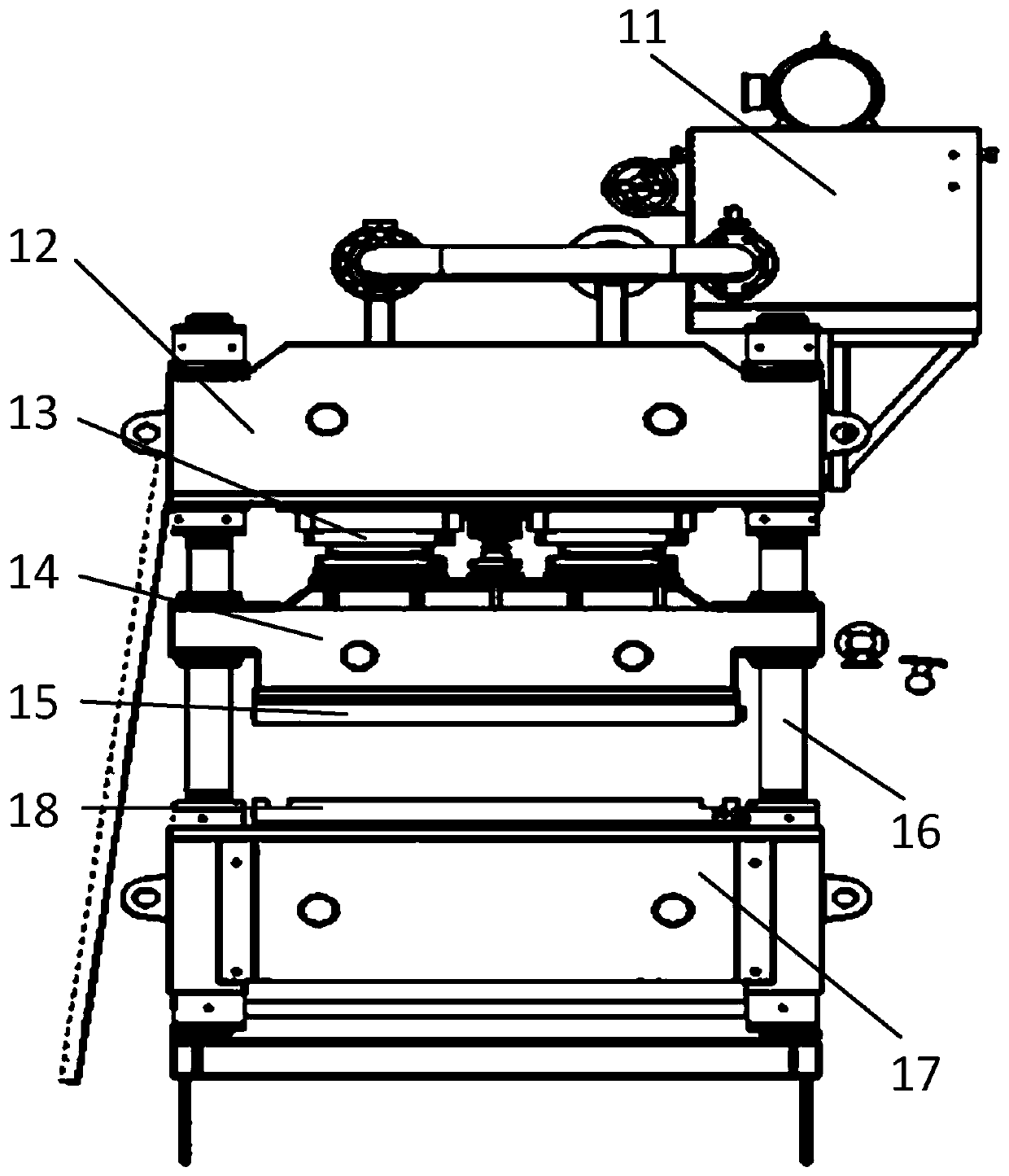

[0033] The following is based on Figure 1 to Figure 4 A specific embodiment of the plate embossing device according to the present invention will be described in detail.

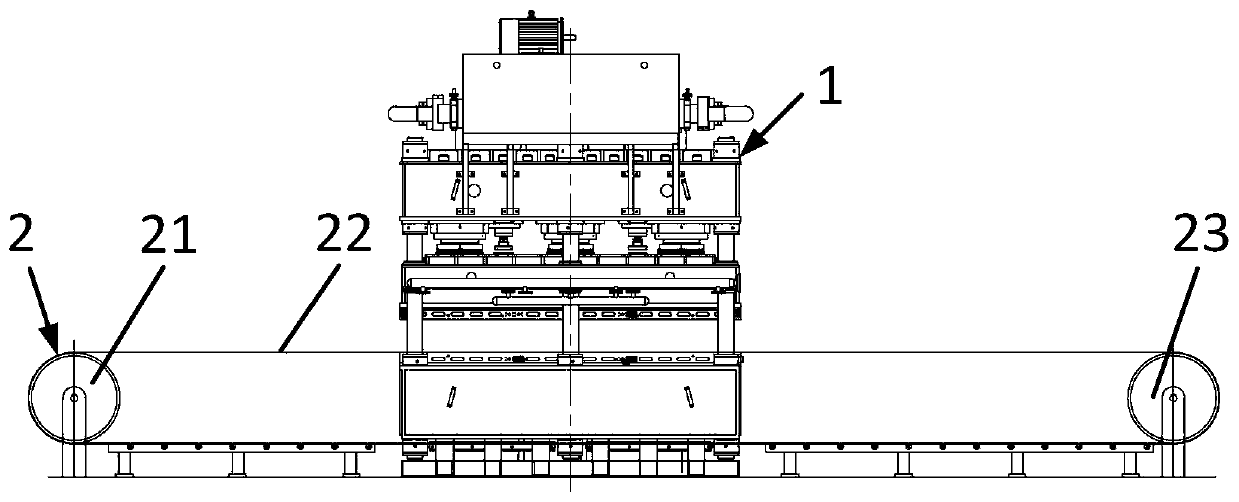

[0034] In this embodiment, if figure 1 As shown, the plate embossing device according to the present invention includes a hydraulic press 1 and a steel belt conveying device 2 .

[0035] In this embodiment, if figure 1 , figure 2 and image 3 As shown, the hydraulic press 1 includes a power unit 11 , an upper beam 12 , an oil cylinder 13 , a slider 14 , an upper platen 15 , a column 16 , a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com