Multifunctional hydraulic support equipment

A hydraulic support and multi-functional technology, applied in mining equipment, mine roof support, earthwork drilling and mining, etc., can solve the problems of reduced mechanization efficiency, increased operation risk factor, and inability to adjust the space between the supports, so as to avoid the reduction of the working space , Reduce the empty top working space, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

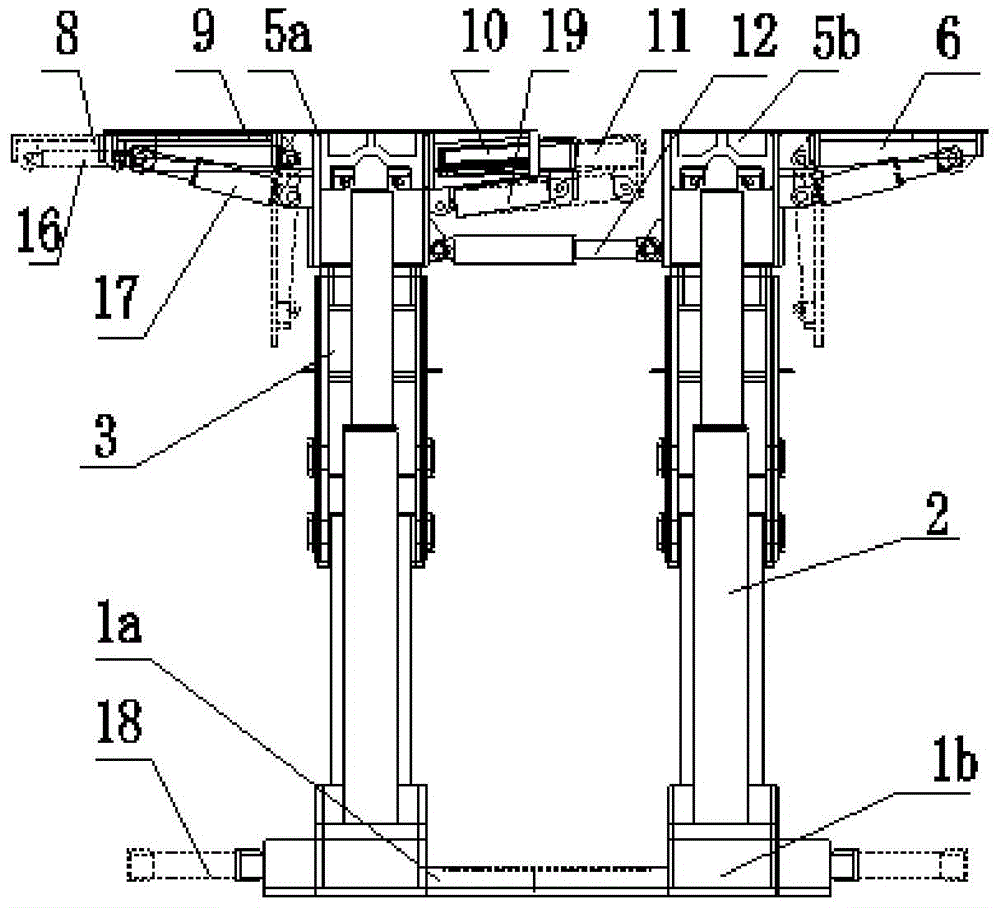

[0052] Such as Figure 5 shown as figure 1 It is a schematic diagram of the multifunctional hydraulic support device of the present invention when it is in the working state of the end hydraulic support.

[0053] When the multi-functional hydraulic support equipment is used as the end hydraulic support, on the one hand, it has the function of the end hydraulic support of the fully mechanized coal mine caving face in the traditional coal mine; on the other hand, it can be According to the changes in the displacement of each support on the working face, which lead to different degrees of empty roof and the change of the severity of roof breakage, timely adjustments are made, so as to achieve the functions of all-round support and frame adjustment, as follows.

[0054] 1) When the distance L between the end hydraulic support and the nose transition support 21 is too large, the top beam can be fully enclosed and supported by raising the flip beam 9 and extending the telescopic be...

Embodiment 2

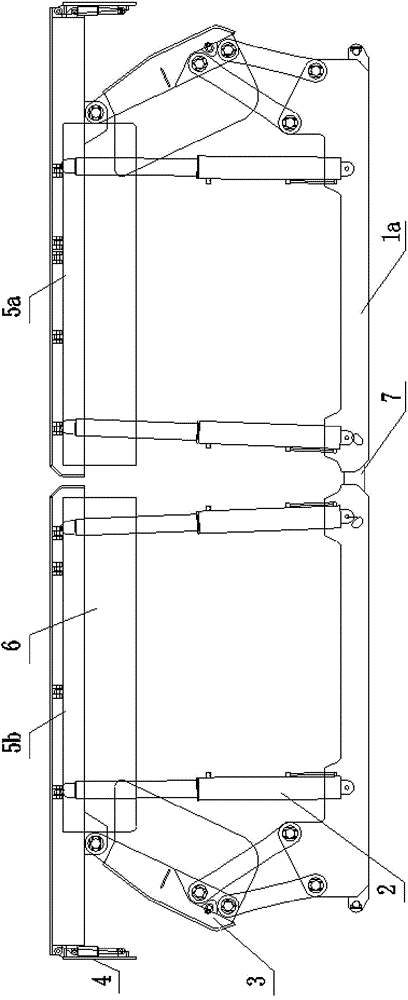

[0058] Such as Image 6 shown as Figure 4 Shown is a schematic diagram of the multifunctional hydraulic support device of the present invention in the working state of the end-to-tail hydraulic support of a large-inclination working face.

[0059] When the multi-functional hydraulic support equipment is used as the end-tail hydraulic support, when the width of the working face changes irregularly and the frame needs to be reduced or increased, its structure and function can be increased or increased by extending or shortening the top beam. The function of frame reduction can not only avoid the empty top operation on the working face, but also use the bottom adjustment beam to achieve the frame adjustment function between adjacent supports on the working face, the details are as follows.

[0060] 1) Since the front and rear groups of hydraulic supports of the multifunctional hydraulic support device of the present invention are structurally the same, on the same fully mechani...

Embodiment 3

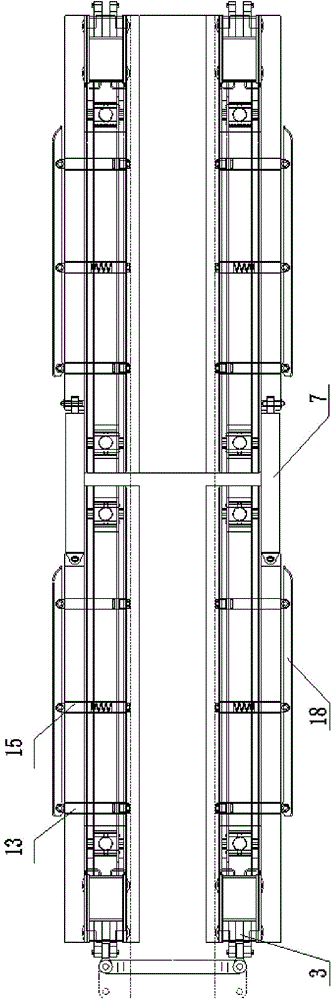

[0065] Such as Figure 7 As shown, it is a schematic diagram of the multifunctional hydraulic support device of the present invention in the working state of the advance support support.

[0066] When the two outlet roadways of the fully mechanized top-coal caving face in the coal mine need to be supported in advance due to incoming pressure, etc., the multifunctional hydraulic support device of the present invention can be used as the advance support support.

[0067] 1) When the width of the roadway becomes larger or comes under pressure, the upper end of the advance support bracket can be fully closed and supported by raising the overturning beam 9 and stretching the telescopic beam 8; on the contrary, falling back and retracting. And both sides of the lower end of the advance support support can reduce the displacement of the coal wall 23 by extending the bottom adjustment beam 18 and pushing the sleepers 20 etc., so as to ensure that the advance support support is not clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com