Ramjet circumferential air inlet distortion restraint grating and design method thereof

A technology of ramjet engine and design method, which is applied in the field of ramjet engine, can solve the problems such as the shape of small holes in the grid, the clogging degree of aperture size, the difficulty of ensuring the effect of airflow distortion suppression, and the aerodynamic resistance of small engines, so as to achieve convenient control , Increase the stability of the working margin, reduce the effect of internal aerodynamic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

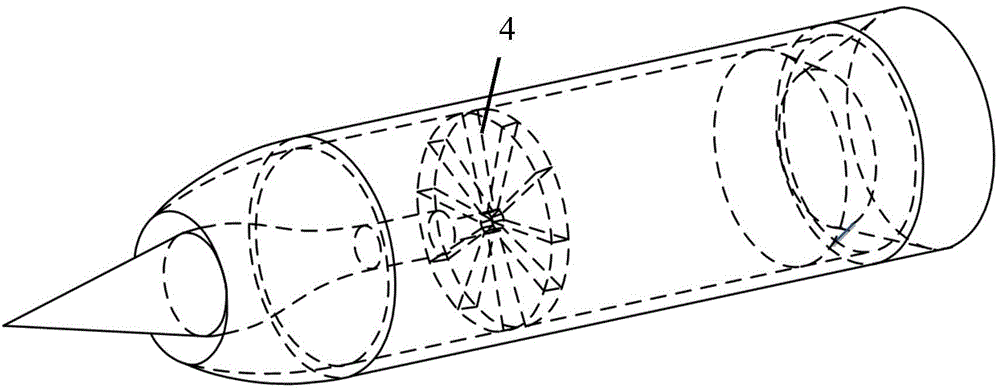

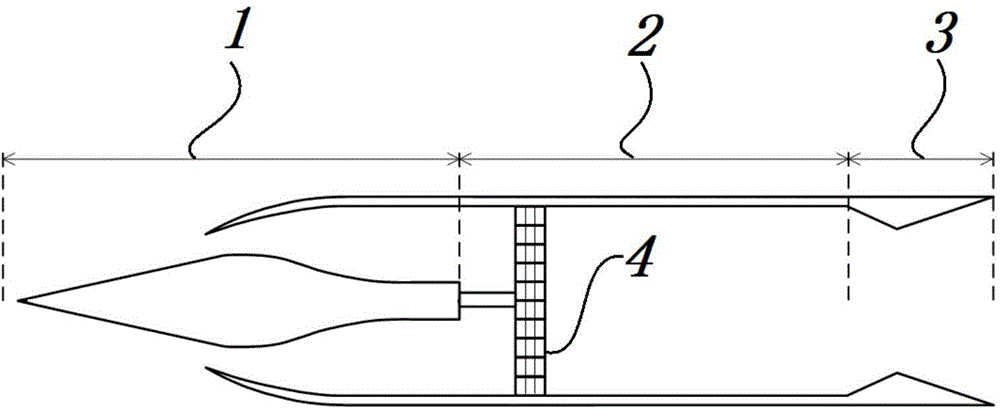

[0036] Such as figure 1 and figure 2 As shown, the circumferential intake distortion suppression grille 4 of the ramjet of the present invention is installed in the internal flow channel of the ramjet. A conventional ramjet engine consists of a diffuser 1, a combustion chamber 2 and a nozzle pipe 3, and the inlet cross section of the combustion chamber 2 is circular. The circumferential air intake distortion suppression grille of the ramjet engine according to the present invention is installed at the entrance of the combustion chamber 2 .

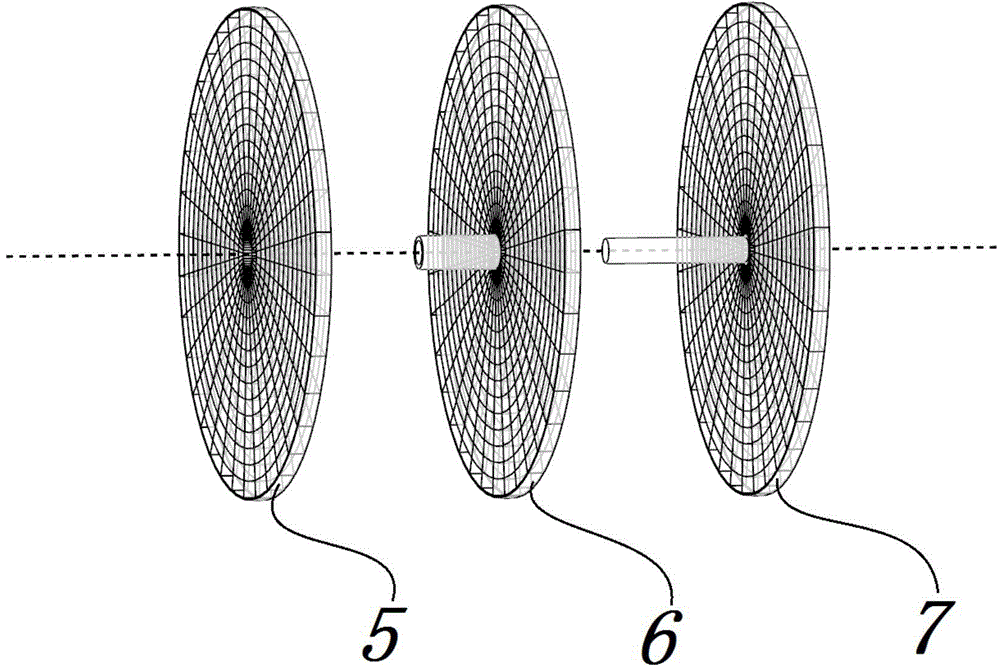

[0037] Such as image 3 and Figure 4 As shown, the embodiment of the circumferential intake distortion suppression grid of the ramjet is provided with three first distortion suppression grid pieces 5 , second distortion suppression grid pieces 6 and third distortion suppression grids stacked in series in sequence. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com