Exhausting and re-circulating rate mechanical control mechanism

A technology of exhaust gas recirculation and mechanical control, applied in the direction of exhaust gas recirculation, engine control, mechanical equipment, etc., can solve problems such as complex control systems, and achieve the effect of reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

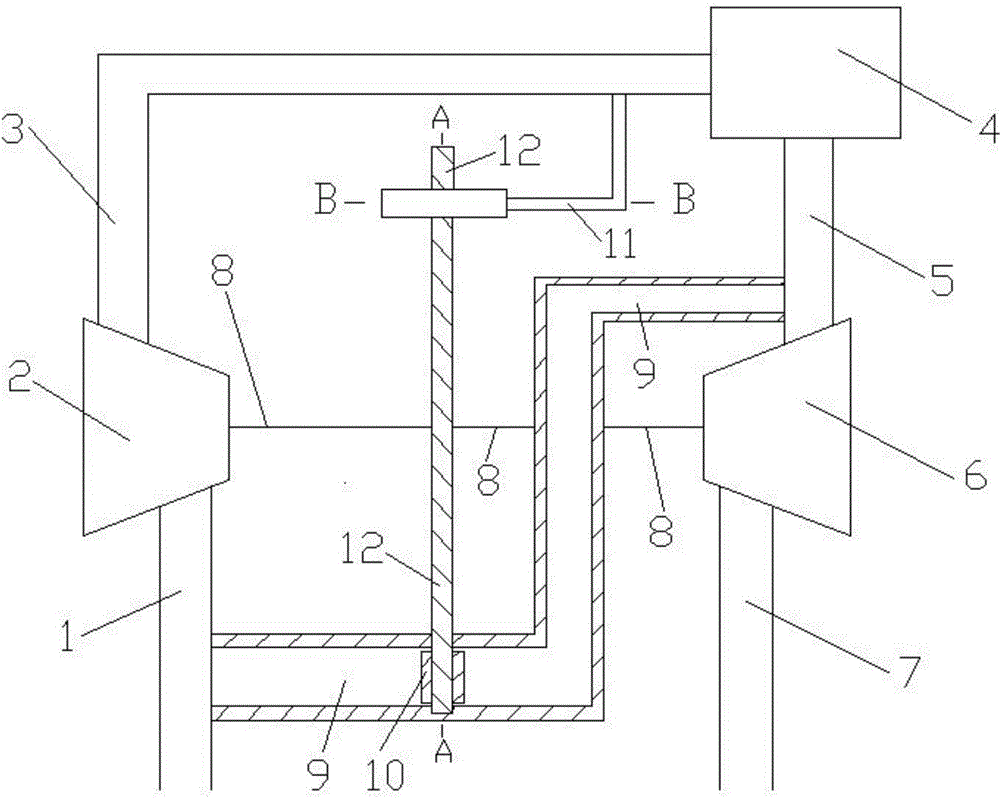

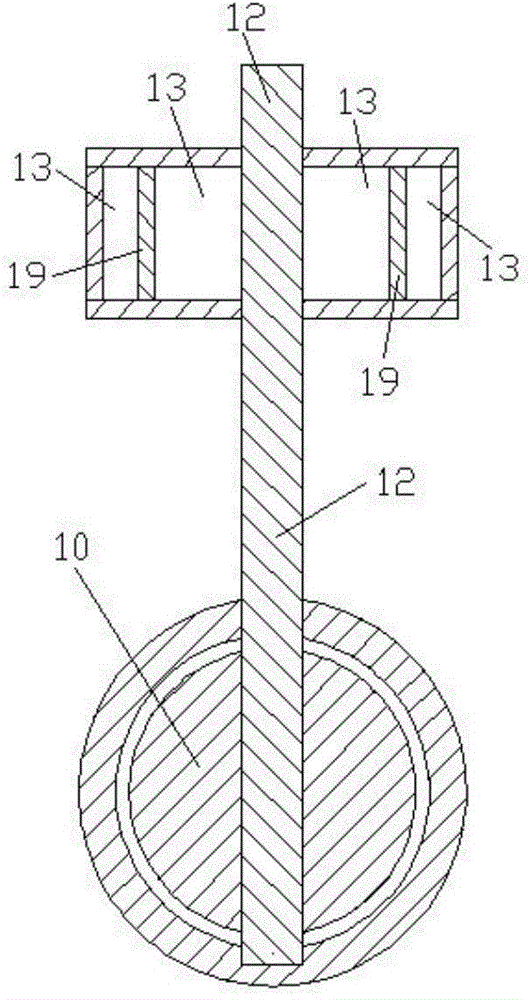

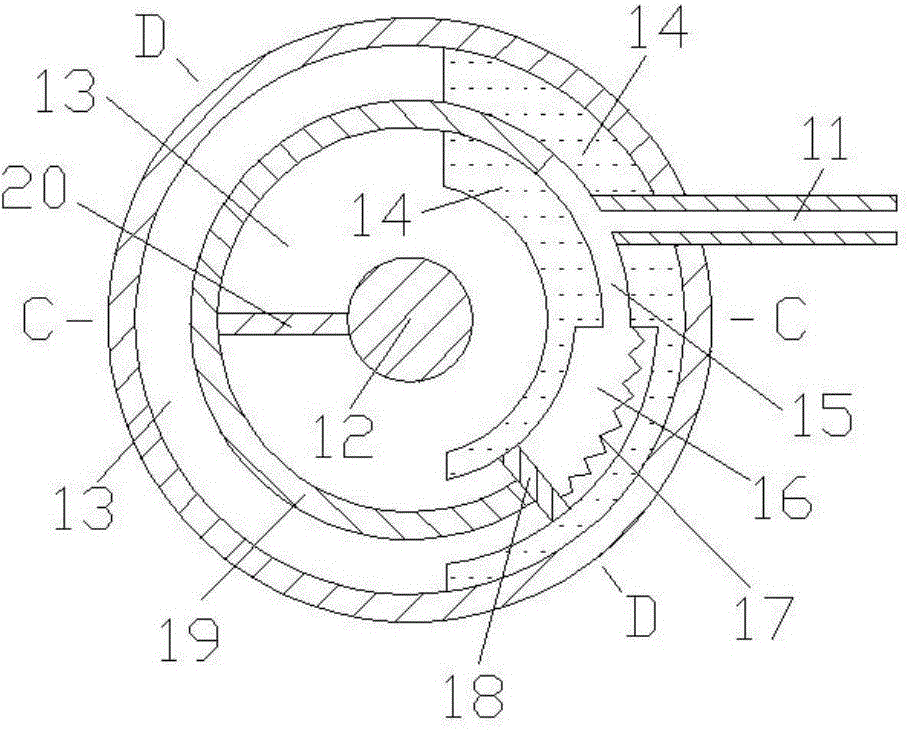

[0017] Such as Figure 1 to Figure 5 As shown, the present invention comprises compressor intake pipe 1, compressor 2, engine intake pipe 3, engine 4, engine exhaust pipe 5, turbine 6, turbine exhaust pipe 7, connecting shaft 8, first connecting pipe 9, valve 10. Second connecting pipe 11, rotating shaft 12, volume cavity 13, fixed body 14, first through pipe 15, second through pipe 16, elastic member 17, partition 18, rotating body 19 and connecting plate 20, compressor The air inlet and outlet of 2 are respectively connected with the air outlet of compressor inlet pipe 1 and the air inlet of engine air intake pipe 3, and the air inlet and outlet of engine 4 are respectively connected with the air outlet of engine air inlet pipe 3 and the air inlet of engine exhaust pipe 5 The air inlet and outlet of the turbine 6 are connected with the air outlet of the engine exhaust pipe 5 and the air inlet of the turbine exhaust pipe 7 respectively. The cross-section is circular, the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com