Vehicle door checking tool and method for detecting matching degree of inner vehicle door plate and window frame

A technology for car doors and window frames, applied in the field of automobile assembly inspection, can solve the problems of occupying a lot of space, high investment in tooling development, and inability to match quality inspection, and achieve the effect of ensuring inspection accuracy and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

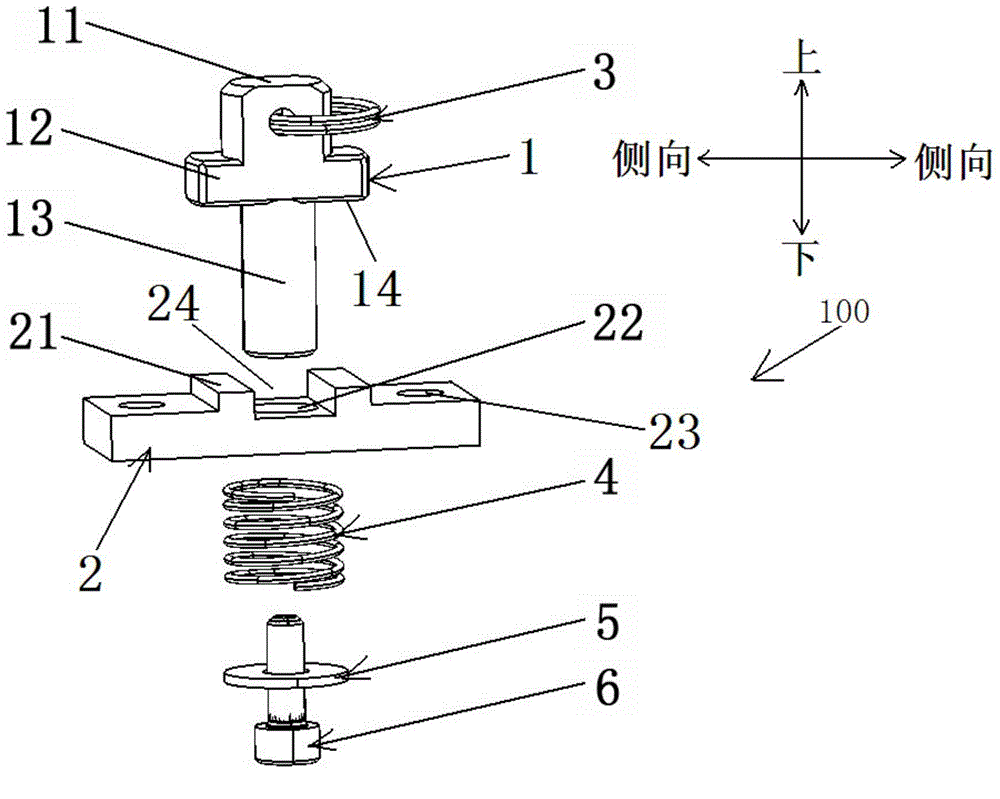

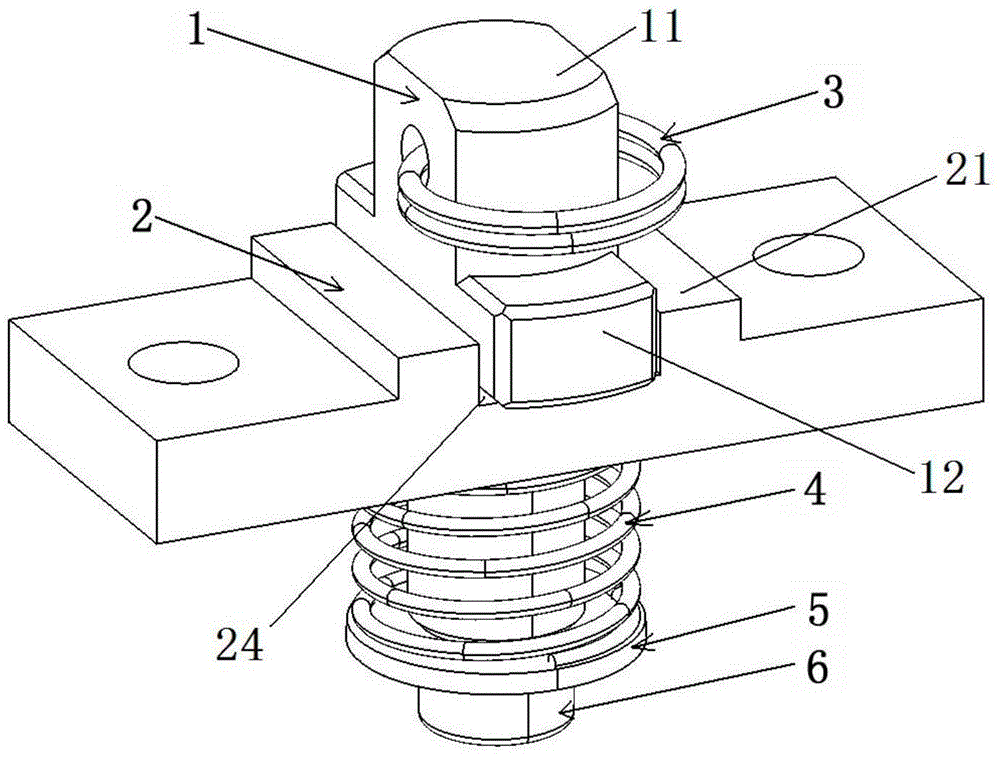

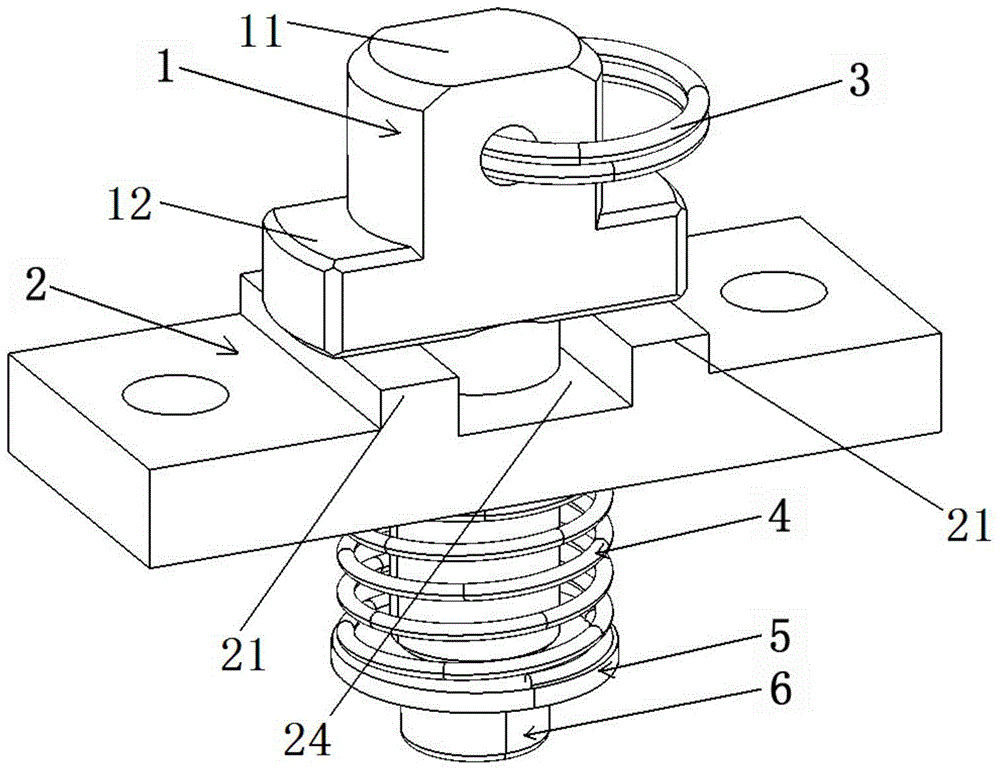

[0042] refer to figure 1, the pull-type inspection tool positioning device 100 in this embodiment includes a reference block 1 , a base 2 , a pull ring 3 , a spring 4 , a stopper 5 and a bolt 6 . The reference block 1 has a top surface 11 and a bottom surface 14, and in operation, the top surface 11 serves as a detection reference surface. Beneath the top surface 11, the datum block 1 has a pair of flanges 12 extending laterally. Beneath the bottom surface 14 the reference block 1 has a round bar 13 extending downwards. The pull ring 3 passes through the through hole on the reference block 1 . The base 2 has a pair of bosses 21 , a groove 24 is formed between the bosses 21 , and a through hole 22 penetrating the base 2 in the vertical direction is opened in the groove 24 . Bolt holes 23 are opened on both sides of the boss 21 . During assembly, after the round rod 13 of the reference block 1 passes through the through hole 22 of the base 2 , the spring 4 is sleeved on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com