Rapid level gauge level-djusting structure

A leveling and leveling technology, applied in the field of leveling structures, can solve the problems of cumbersome initial adjustment process, errors affecting the measurement accuracy of the leveling instrument, etc., and achieve the effect of reducing requirements and facilitating disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

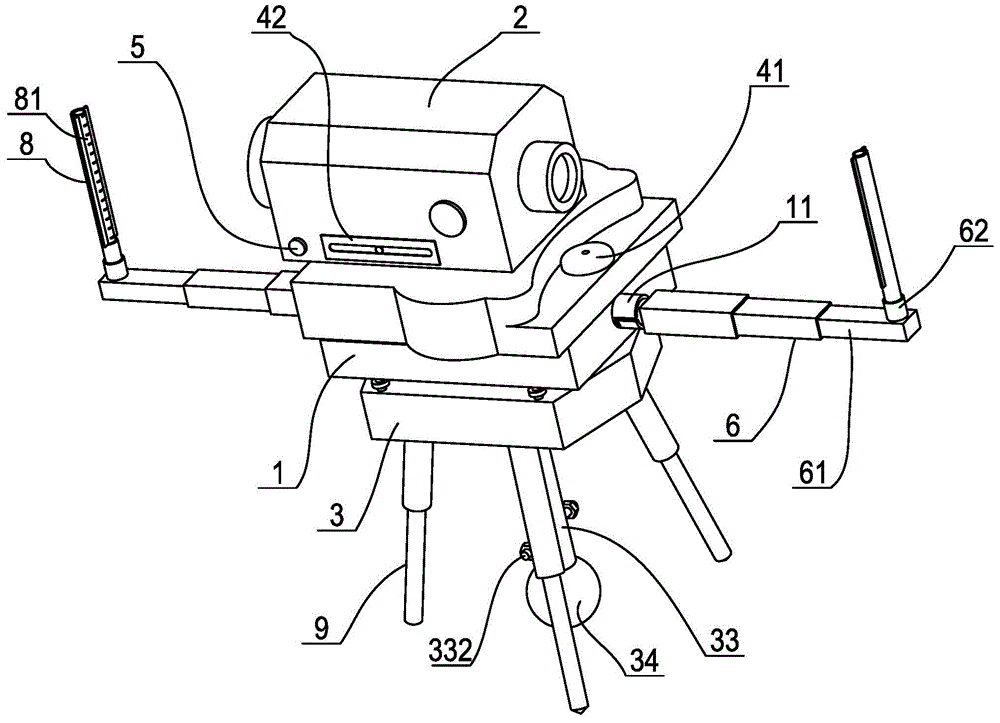

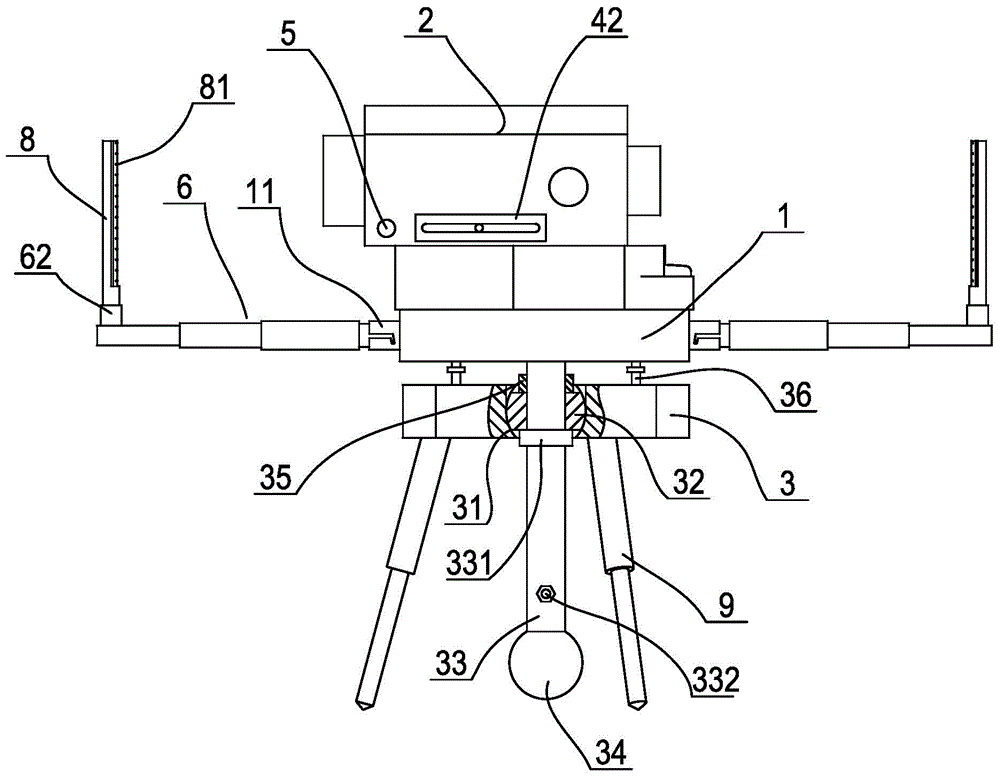

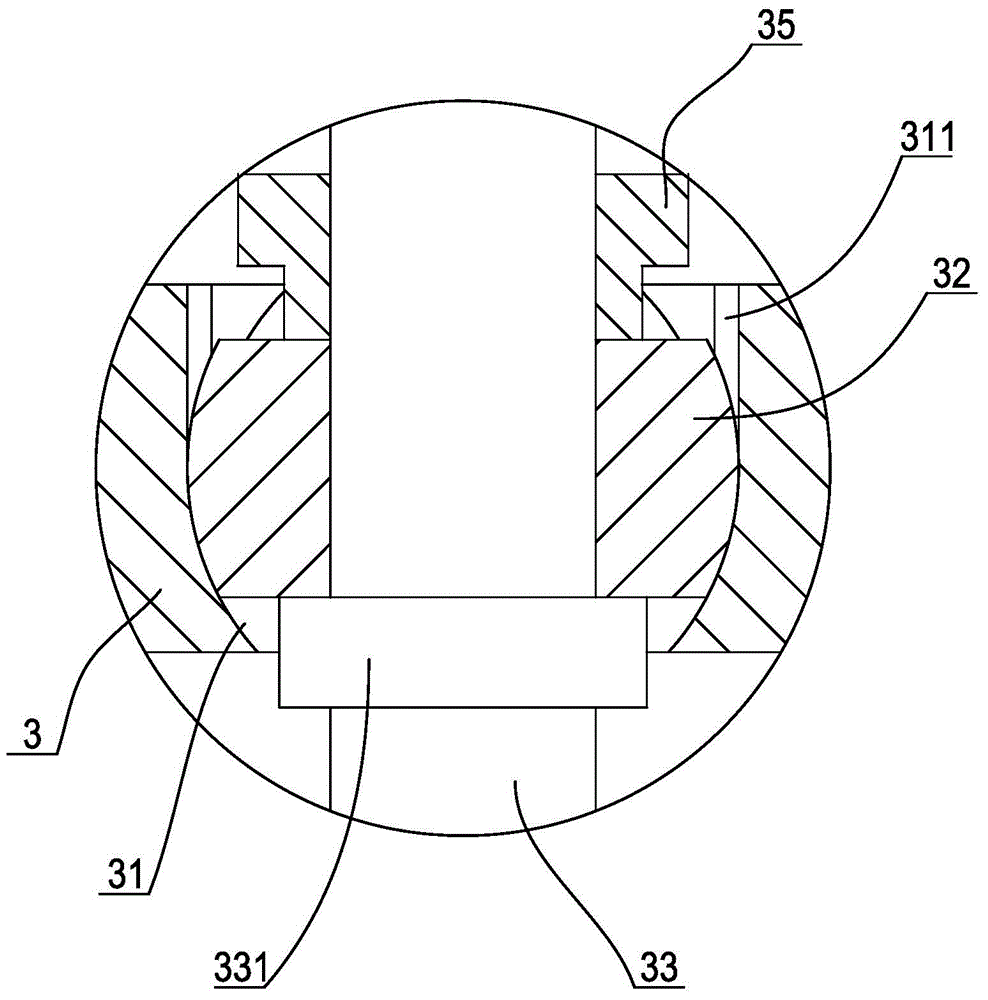

[0026] Such as figure 1 , figure 2 As shown, a quick leveling structure of a level includes a base 2, a level body 2 connected to the upper surface of the base by rotating a vertical axis perpendicular to the upper surface of the base, and a connecting bottom plate 3 arranged at the lower part of the base, A telescope for measuring is arranged in the level body, and a circular level 41 for monitoring the levelness of the initial adjustment program is arranged horizontally at the rear of the level body. The circular level is perpendicular to the collimating axis of the telescope. For the fine-tuning helix 5, a tube level 42 parallel to the collimation axis of the telescope is set on one side of the level body to monitor the parallelism during the fine-tuning procedure. In order to complete the initial adjustment procedure quickly and convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com