Spring deformation performance testing device

A testing device and deformation technology, applied in the direction of measuring devices, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of lamp bracket breakage, light source damage, loss of anti-vibration performance, etc., and achieve low production cost and excellent structure Simple and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

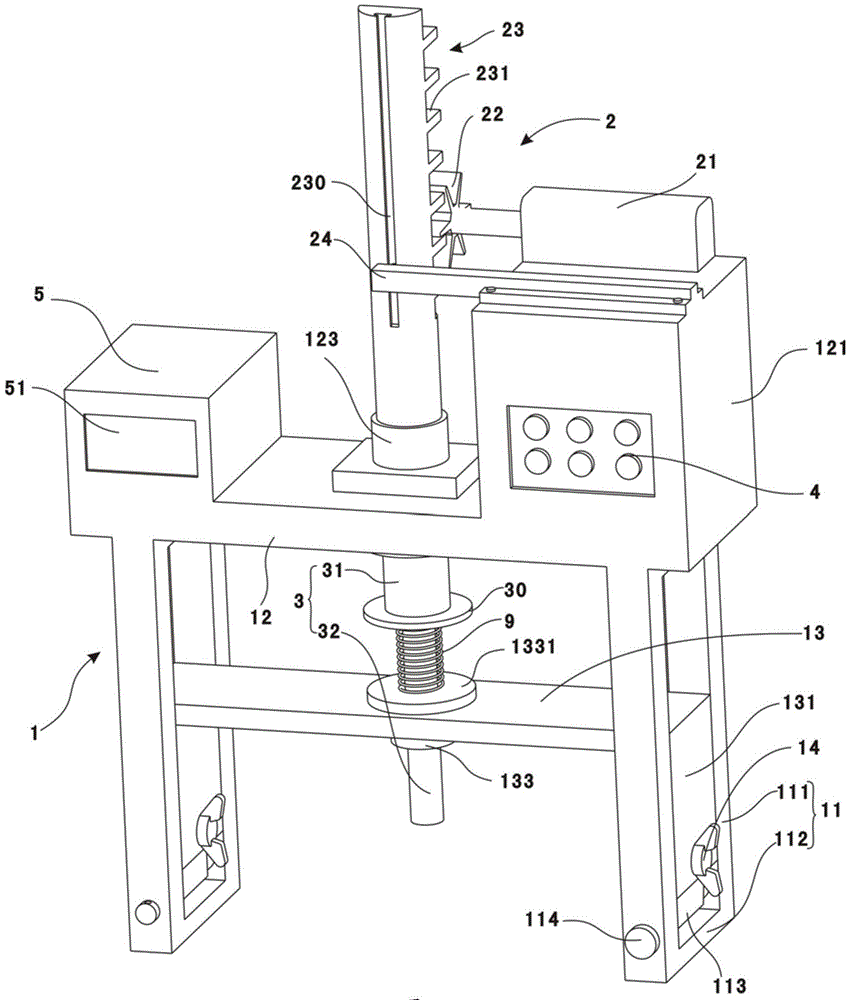

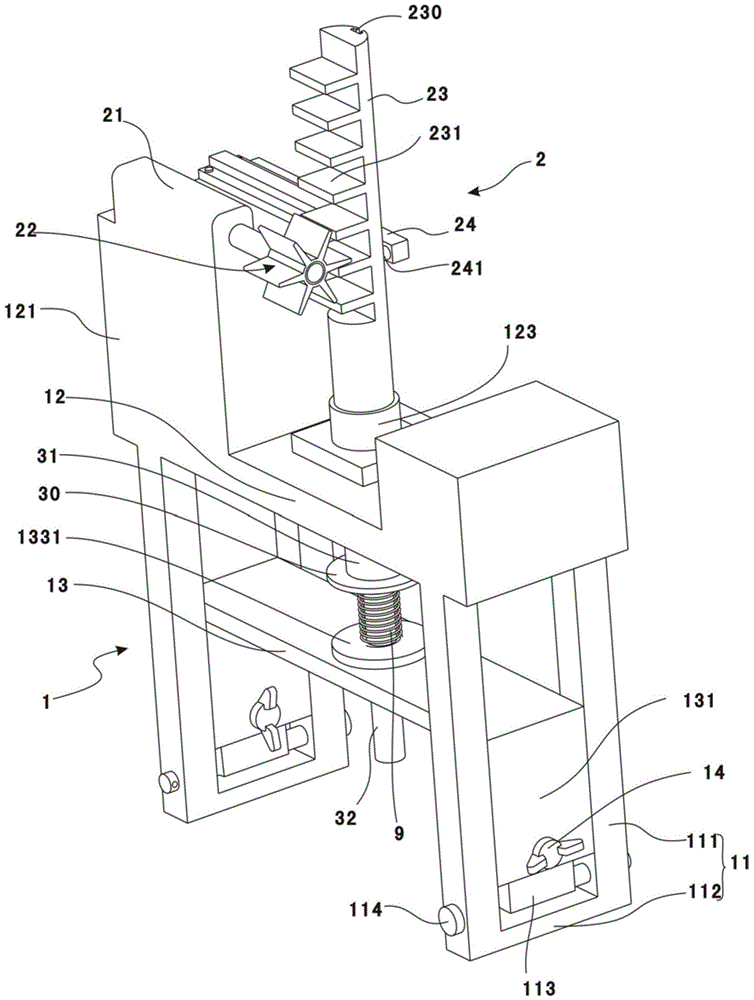

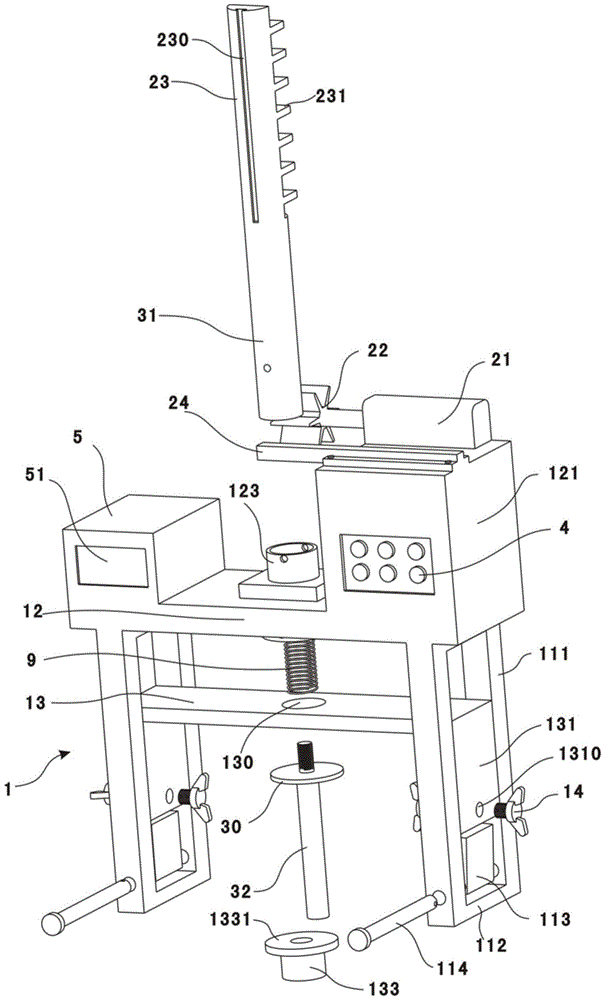

[0024] Please also refer to Figure 1 to Figure 4 , a spring deformation performance test device provided by the embodiment of the present invention includes a bracket 1, a drive assembly 2 and a slide bar 3; the drive assembly 2 and the slide bar 3 are both connected to the bracket 1, and the drive assembly 2 is connected to the slide bar 3 to drive The slide bar 3 reciprocates linearly along the axial direction of the slide bar 3 relative to the support 1 , and the slide bar 3 can drive the tested spring 9 to expand and contract to test the deformation performance of the spring.

[0025] The bracket 1 includes a supporting part 11 , a fixing part 12 and a supporting part 13 . The fixing part 12 is fixedly connected to the supporting part 11 . The bearing member 13 is space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com