Material storage rack for construction project management

A technology for construction engineering and storage racks, applied in tool storage devices, manufacturing tools, etc., can solve the problems that the storage racks do not have the ability to adjust the size of the space, the materials have no storage space protection, and the space cannot be fully utilized to achieve enhanced parking stability performance, enhanced moisture-proof effect, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

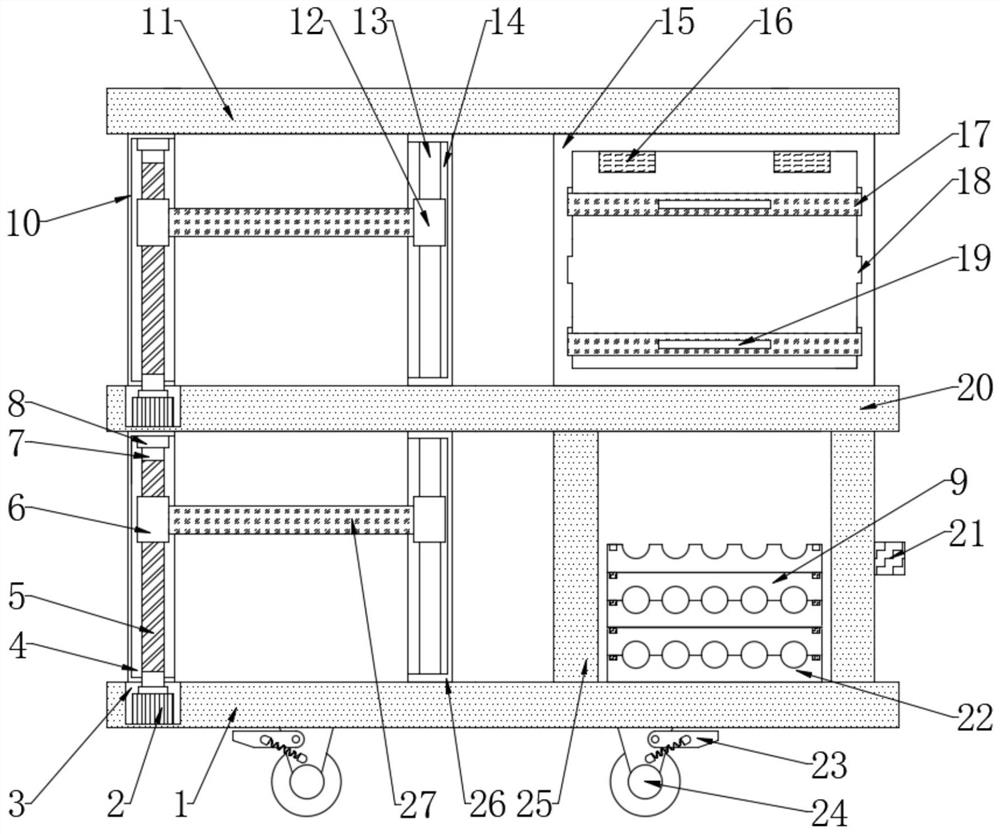

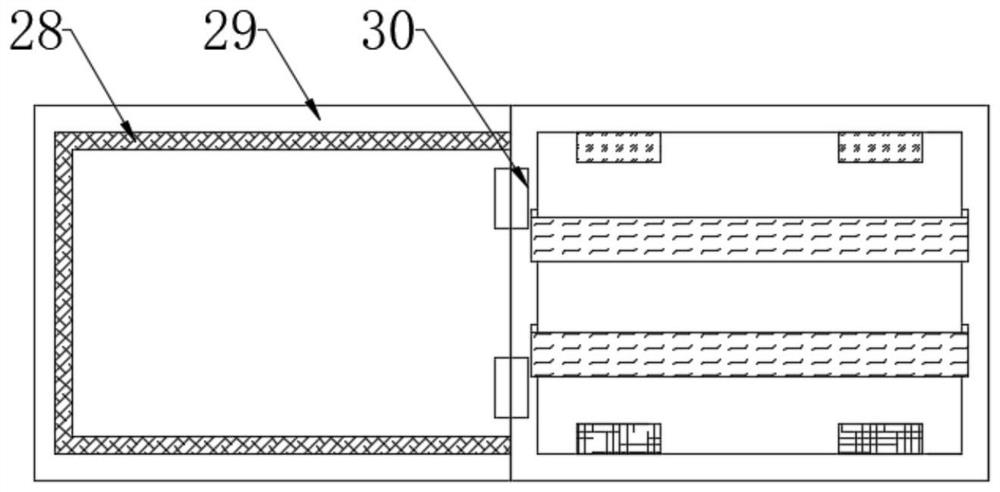

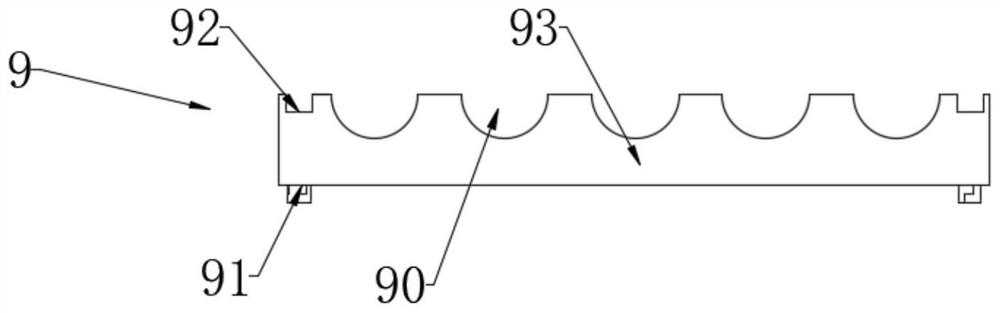

[0020] see Figure 1-4 , the present invention provides the following technical solutions: a material storage rack for construction engineering management, including a base 1, the top of the base 1 is fixedly connected with a first support plate 10 and a third support plate 26, and the first support plate 10 A first chute 4 is opened inside, a first groove 3 is opened in the base 1, a motor 2 is fixedly connected to the first groove 3, and the output shaft of the motor 2 passes through the first chute 4 And fixedly connected with a threaded column 5, one end of the threaded column 5 is fixedly connected with a rotating shaft 7, the surface of the rotating shaft 7 is rotatably connected with a bearing 8, and the bearing 8 is fixedly connected at the top of the inner wall of the first chute 4, the The surface of the threaded column 5 is threadedly connected with a threaded cap 6, and a second chute 14 is provided in the third support plate 26, and a sliding rod 13 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com