Automatic pastry storing machine

A noodle storage machine, automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low production efficiency, no storage function of the whole machine, broken dough cakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

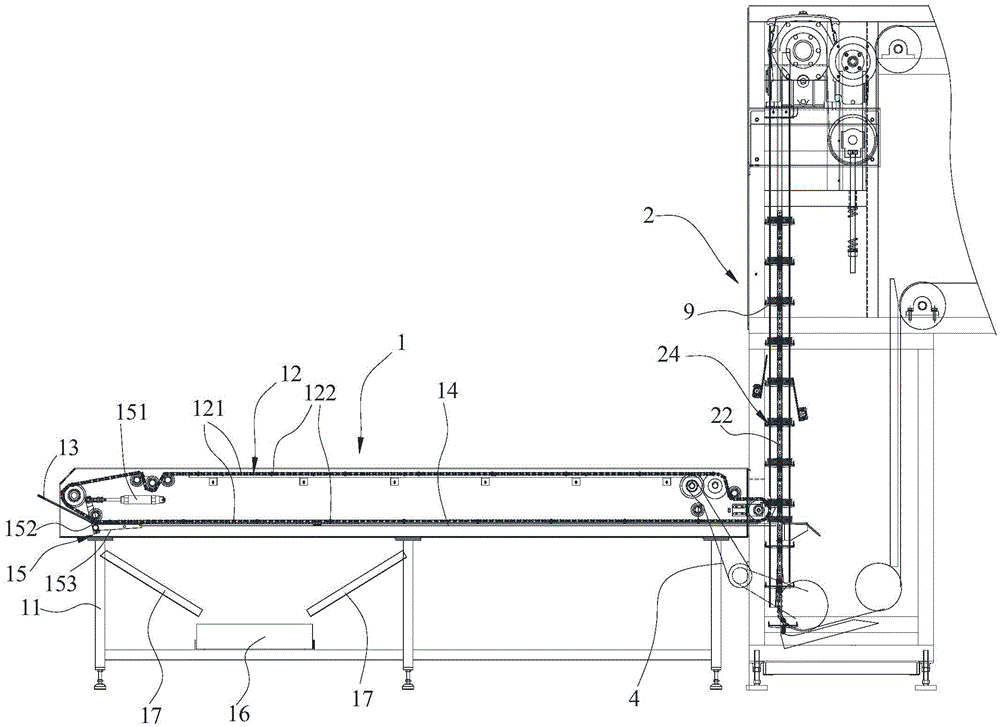

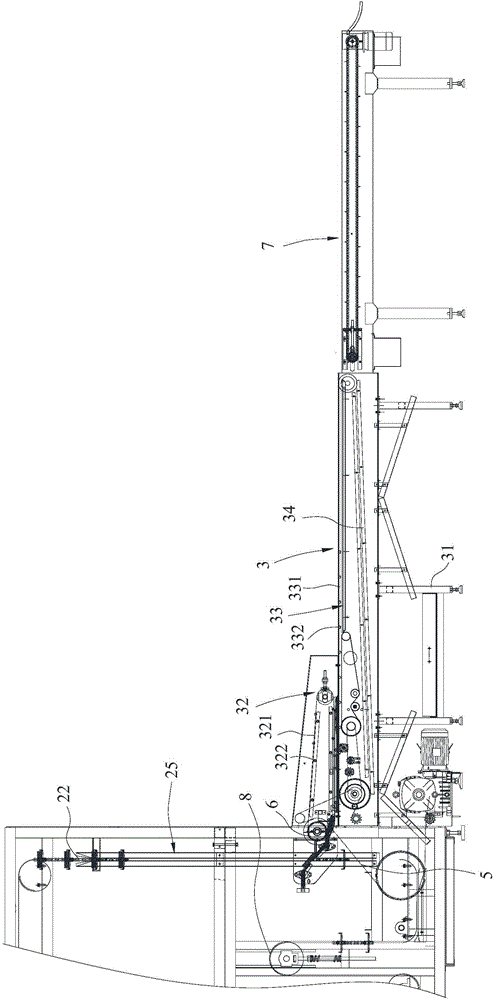

[0023] Such as Figure 1~3 The automatic noodle storage machine shown includes: front arranging machine 1, noodle storage mechanism 2 and rear arranging machine 3, wherein:

[0024] Front alignment machine 1, comprises the first frame 11 and the first chain transmission mechanism 12 that is all installed on this first frame 11, slide plate 13, the first guide rail 14 and the discharge mechanism 15 that is used to discharge dough cake, the first A chain transmission mechanism 12 is positioned at the top of the first guide rail 14 and is arranged horizontally. The first chain transmission mechanism 12 has a first chain 121. A plurality of first driving levers 122 are fixed at equal intervals on the first chain 121. Slide plates 13, discharge The mechanism 15 and the first guide rail 14 are arranged sequentially along the transmission direction of the first chain transmission mechanism 12;

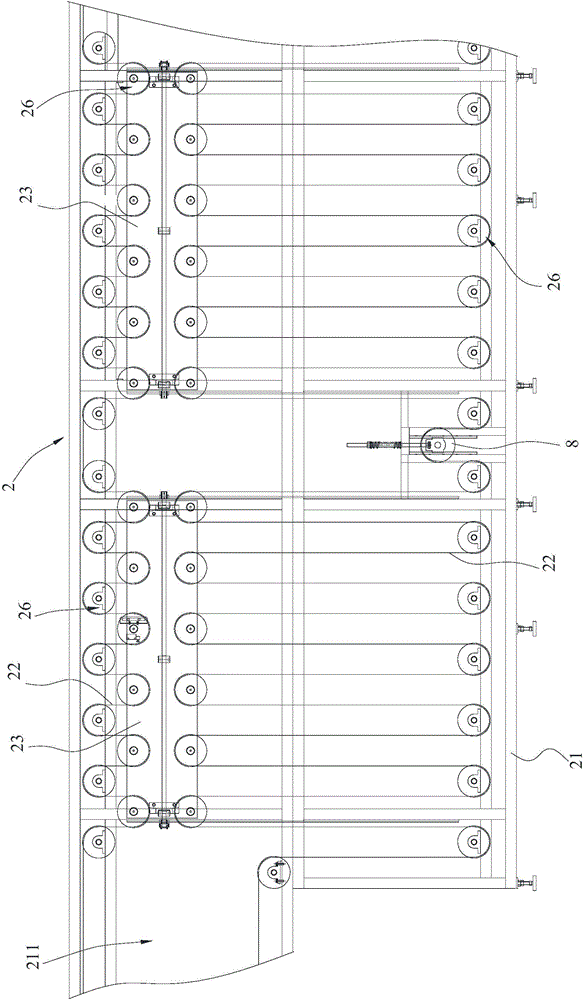

[0025] The surface storage mechanism 2 includes a second frame 21, a transmission chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com