Incident wave control method for electromagnetic-force Hopkinson pressure bar and torsion bar experiment loading device

A Hopkinson pressure bar and loading device technology, applied in program control, measuring device, computer control, etc., can solve problems such as poor practicability, avoid errors, improve the maximum amplitude and rising edge slope, and increase the maximum pulse amplitude. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

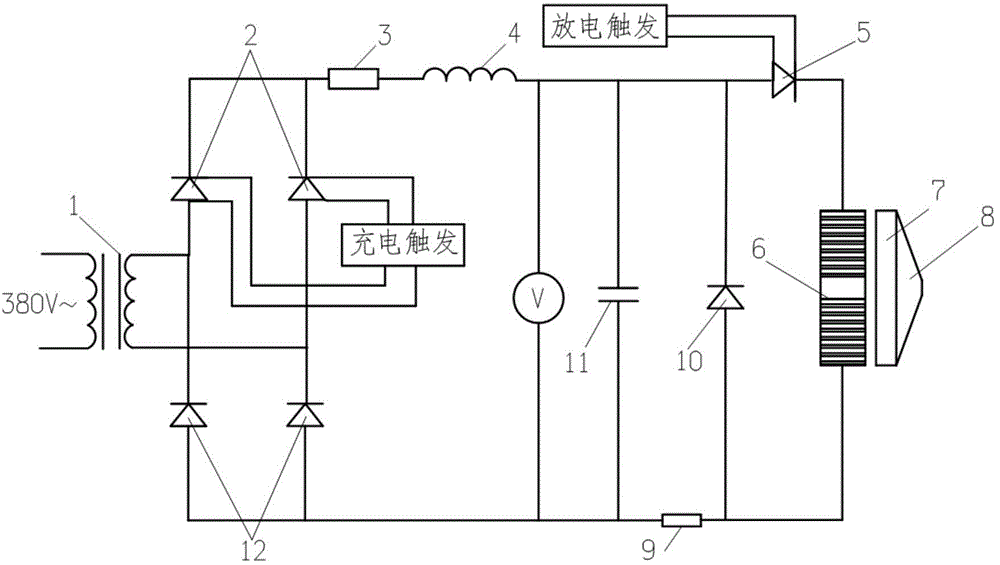

[0038] refer to Figure 1-9 . The specific steps of the incident wave control method of the electromagnetic force Hopkinson compression rod and pull rod experimental loading device of the present invention are as follows:

[0039] 1. The working state of the discharge circuit.

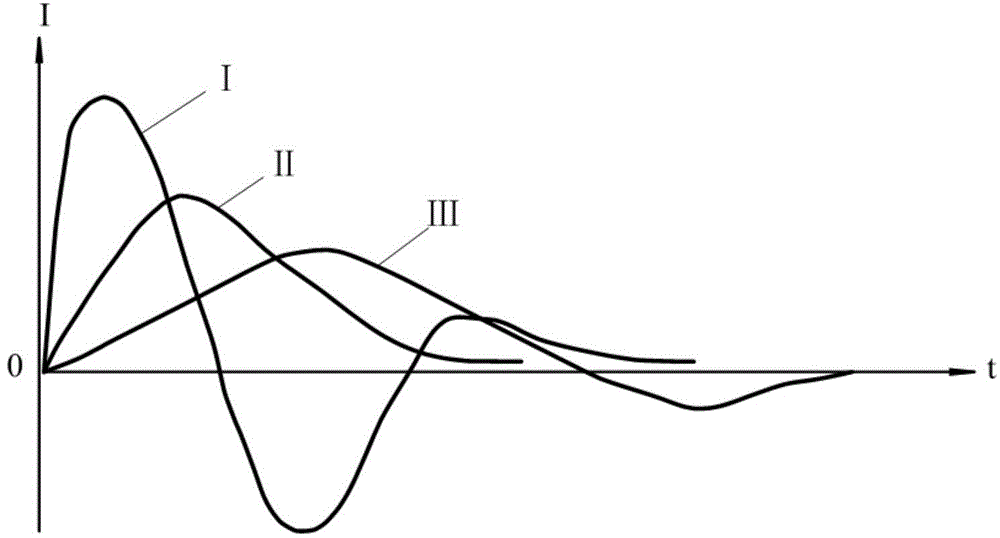

[0040] The principle of electromagnetic force stress wave loading is the same as that of electromagnetic riveting, and its discharge circuit is an RLC oscillation circuit. The selected parameters of the discharge circuit are different, and the RLC oscillation circuit has three working states: under-damped state, critically damped state and over-damped state. Under the same discharge conditions, the discharge current pulse amplitude in the underdamped state is the largest, the rising edge is the steepest, and the pulse width is the narrowest, which is conducive to improving the electromagnetic force incident wave amplitude and rising edge slope, and reducing the difficulty of incident wave control. I...

PUM

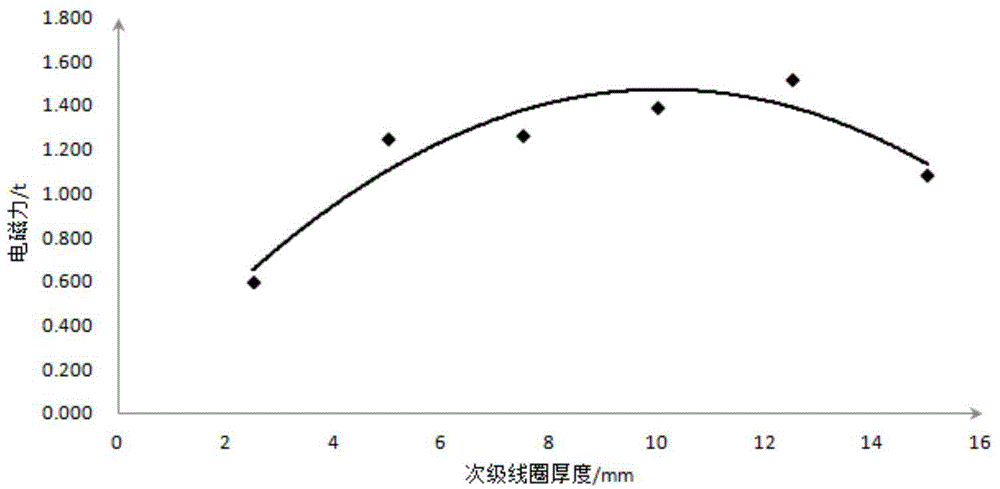

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com