Method and device for controlling water temperature heating based on power feedback assisting

A heating control device and heating control technology, which are applied in the direction of temperature control using electric methods, can solve problems such as inappropriate temperature programs, and achieve the effects of improving adaptability and stability, reducing water temperature fluctuations, and responding to sudden voltage changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

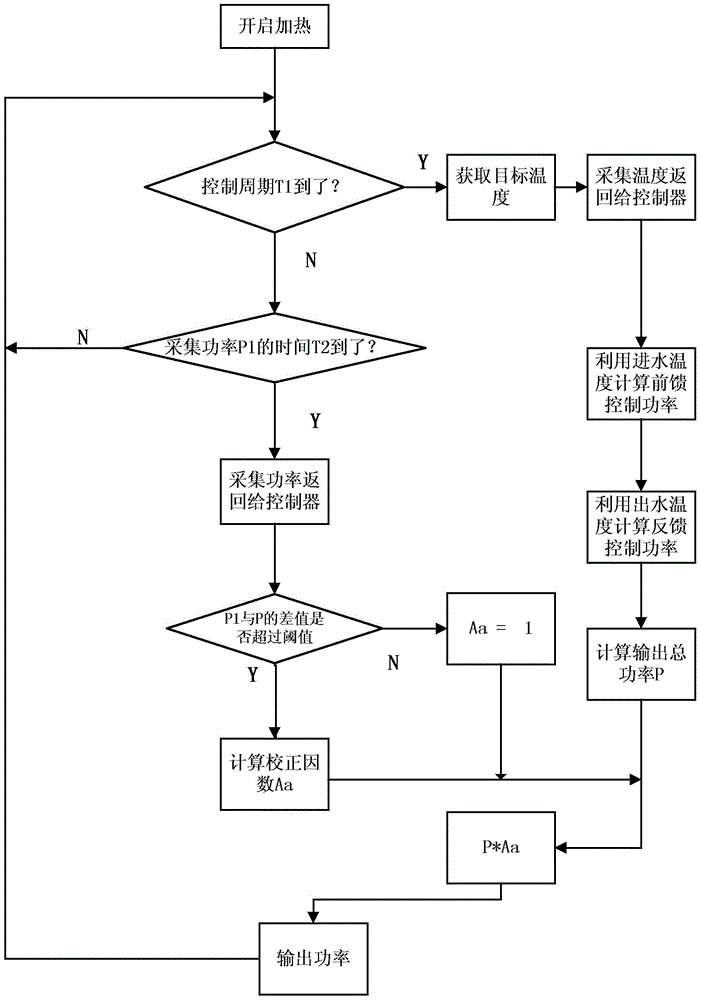

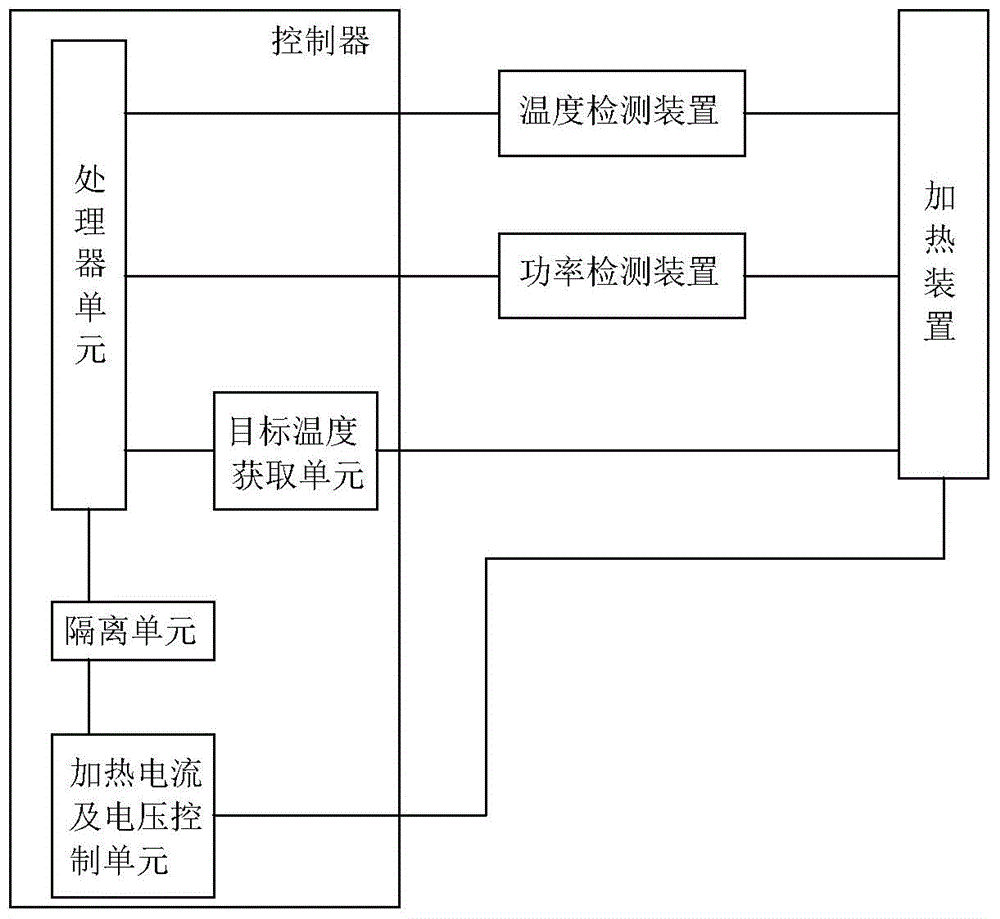

[0040] A water temperature heating control method assisted by power feedback. After heating is started, the target water temperature and real-time water temperature are obtained, and heating is performed according to the theoretical power of the heating device; at the same time, the actual heating power of the heating device is detected, and the actual heating power is compared with the theoretical output. Power, to correct the heating power of the heating device. Make the actual heating power as close as possible to the theoretical output power and keep it stable to achieve the purpose of stable heating and keep the outlet water temperature stable and controllable.

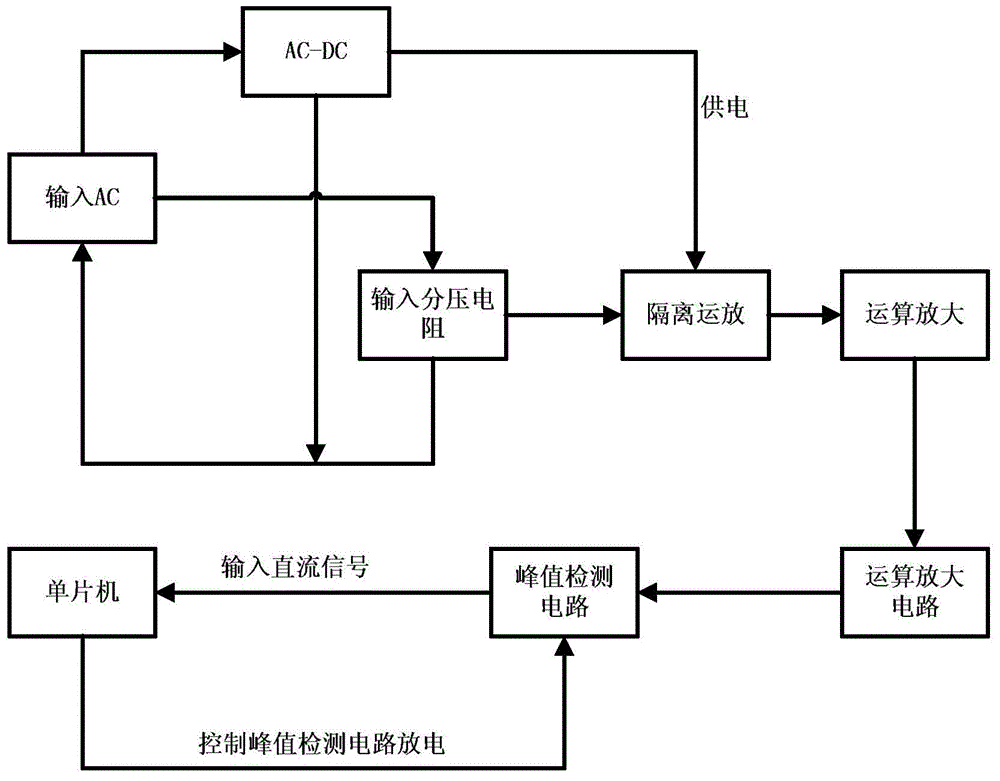

[0041] The heating power of the heating device is corrected, specifically: the real-time voltage is calculated by detecting the actual heating power obtained, and the heating pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com