Template device for cable group wiring

A cable group and template technology, applied in the direction of electrical components, etc., can solve the problems of difficult fixing, poor working reliability, and narrow range of applicable specifications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

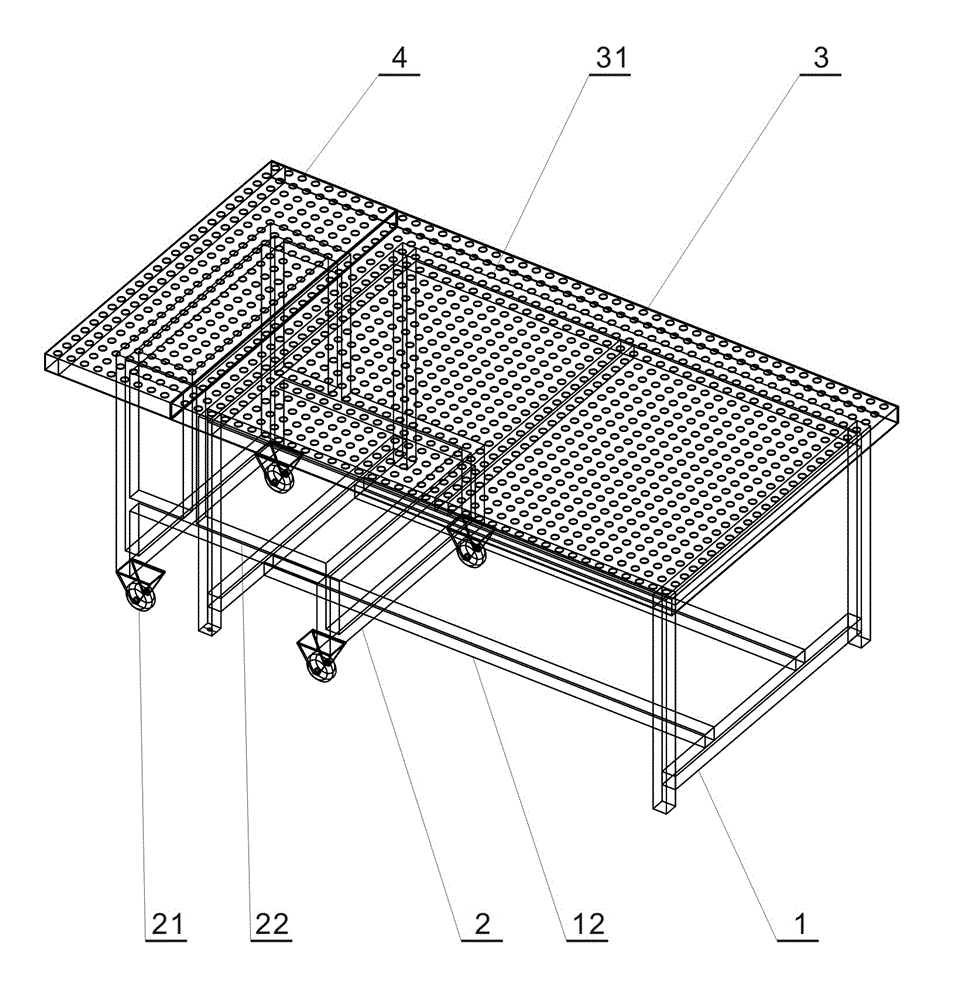

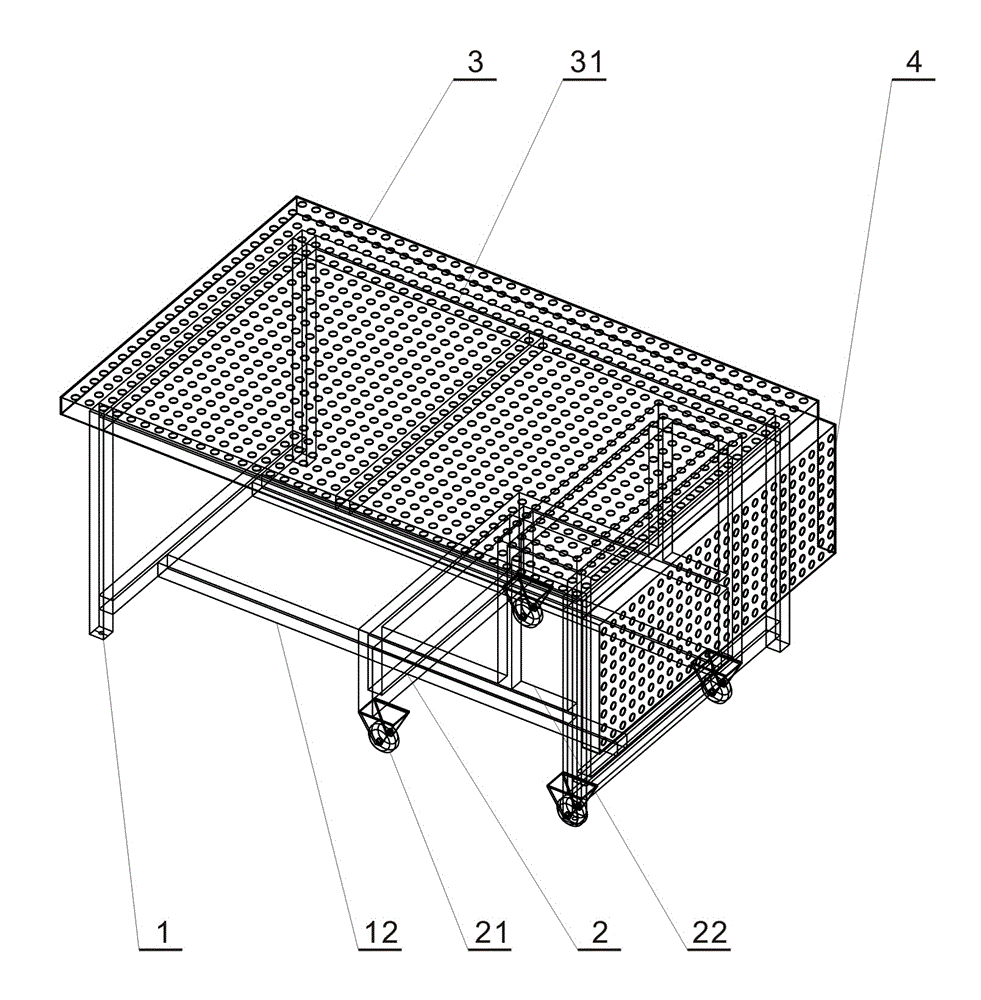

[0020] refer to figure 1 , figure 2 , the present invention comprises main frame 1, auxiliary frame 2, main formwork 3 and auxiliary formwork 4, and described main frame 1 is rectangular frame body, and horizontal slide rail 12 is arranged in its frame along axial direction, and auxiliary frame 2 is rectangular The frame body is provided with a chute 22 inside the frame body, and a roller 21 is provided at the bottom of the frame body. The sub-frame 2 is arranged side by side with the main frame 1, and the chute 22 of the sub-frame 2 slides in the horizontal slide rail 12 of the main frame 1. ;

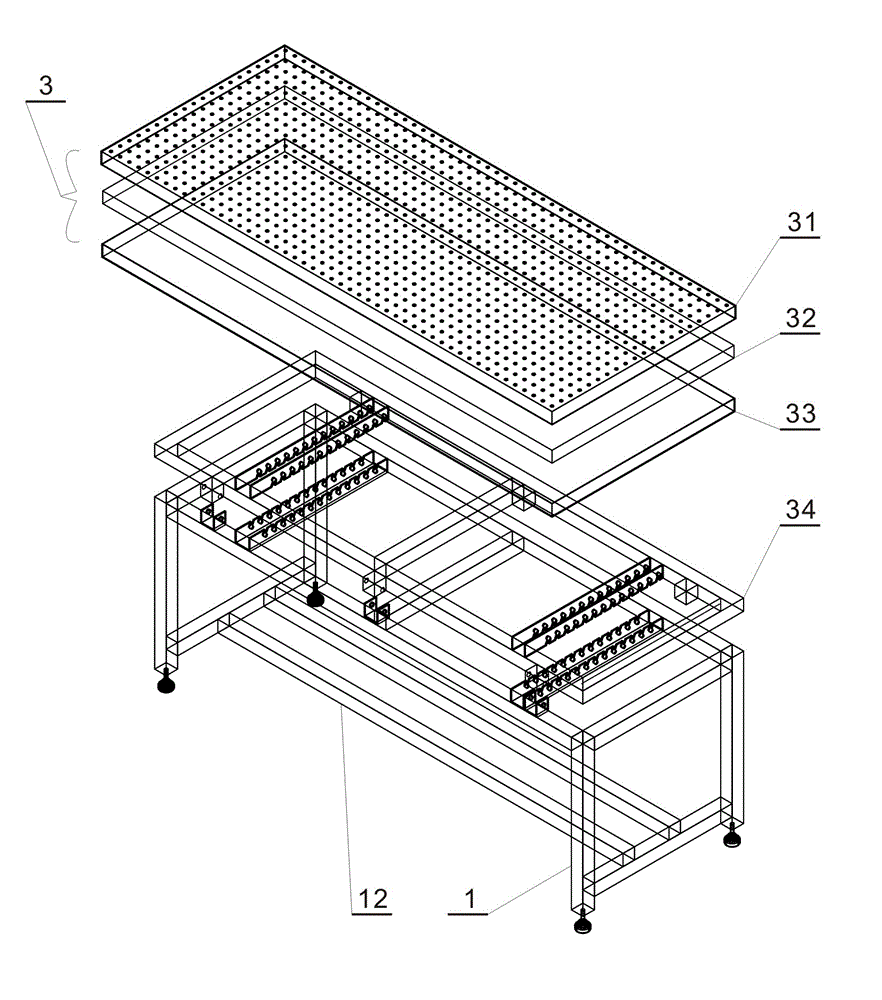

[0021] The main formwork 3 and the auxiliary formwork 4 are all composed of a mesh plate 31, a high-density sponge plate 32, a bottom plate 33 and a panel frame 34, and the bottom plate 33, the high-density sponge plate 32 and the mesh plate 31 are sequentially arranged in the panel frame 34 ;

[0022] One side of the main formwork 3 and the secondary formwork 4 are hinged to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com