A two-degree-of-freedom motor

A technology with a degree of freedom and a casing, applied in the electrical field, can solve problems such as low structural efficiency and low torque per unit current, and achieve good starting performance, reliable operation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

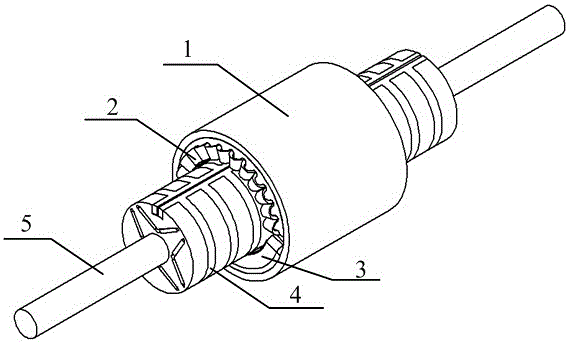

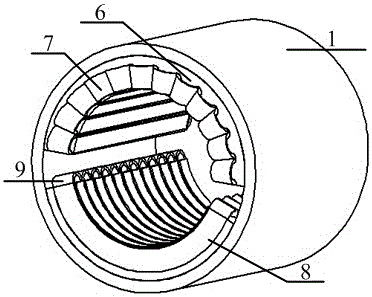

[0018] A two-degree-of-freedom motor, comprising a tubular casing 1 and a rotating shaft 5, the inner wall of the casing 1 is provided with an up-and-down symmetrical rotary motion arc stator 2 and a linear motion arc stator 3, the rotary motion arc An induction-permanent magnet motor mover 4 is arranged in the space surrounded by the arc-shaped stator 2 and the rectilinear motion arc-shaped stator 3; , the linear motion arc stator 3 includes a linear motion arc stator core 8 and a linear motion arc stator winding 9 .

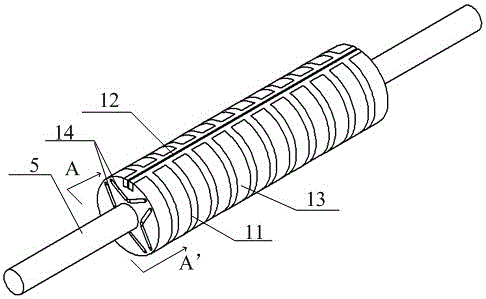

[0019] The induction permanent magnet motor mover 4 includes a plurality of induction iron cores 10 and a plurality of permanent magnet cores 13 that are set on the outside of the rotating shaft 5, and the induction iron cores 10 and the permanent magnet cores 13 are alternately arranged outside the rotating shaft. or are connected by conductor strips 12. The permanent magnet core 13 is formed by laminating circular silicon steel sheets slotted in the axial di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com