LED (Light-emitting Diode) drive circuit and mine explosion-proof lamp

A technology of LED driver and LED module, applied in the field of lighting, can solve the problem of low security of the driving circuit, and achieve the effect of enhancing portability, high security and enhancing security.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

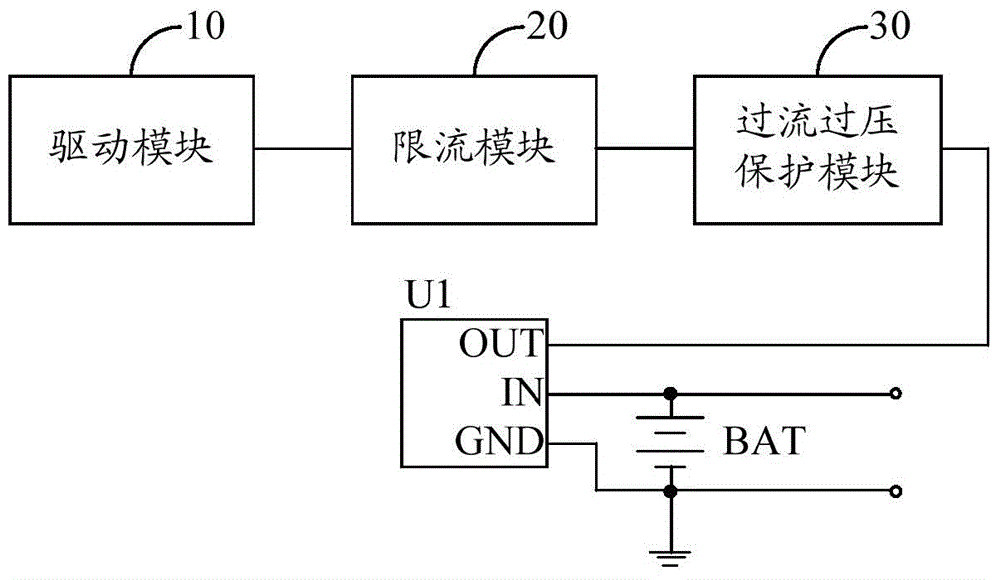

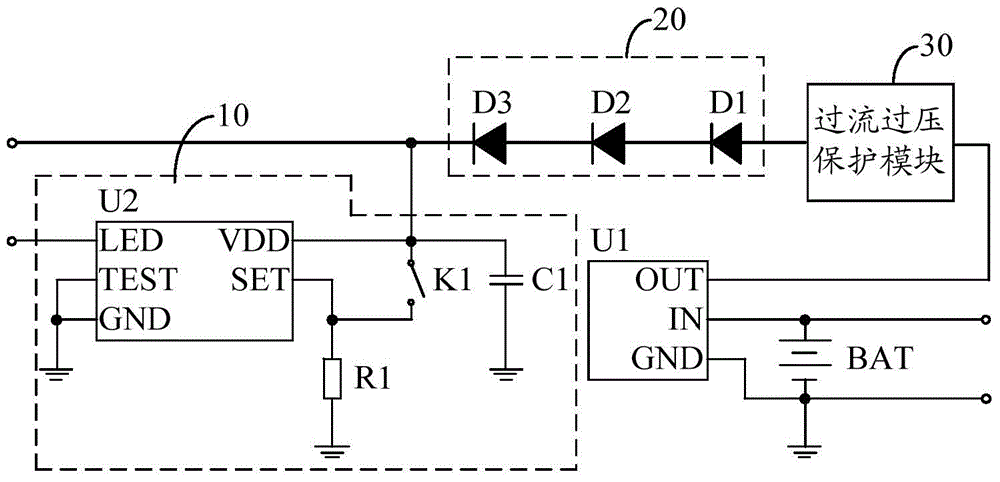

[0020] figure 1 The circuit structure of the LED driving circuit provided by this embodiment is shown. For the convenience of description, only the parts related to this embodiment are shown, and the details are as follows:

[0021] The LED driving circuit provided in this embodiment includes a driving module 10 connected to an LED module and driving the LED module to work.

[0022] Further, the LED driving circuit also includes a mine battery protector U1 , a battery BAT, a current limiting module 20 and an overcurrent and overvoltage protection module 30 .

[0023] Specifically, the positive pole of the storage battery BAT is connected with the input terminal of the mine battery protector U1 to form the positive charging terminal of the LED drive circuit, and the negative pole of the battery BAT is connected with the ground terminal of the mine battery protector U1 to form the negative terminal of the LED drive circuit. The charging terminal is connected to the ground;

[...

Embodiment 2

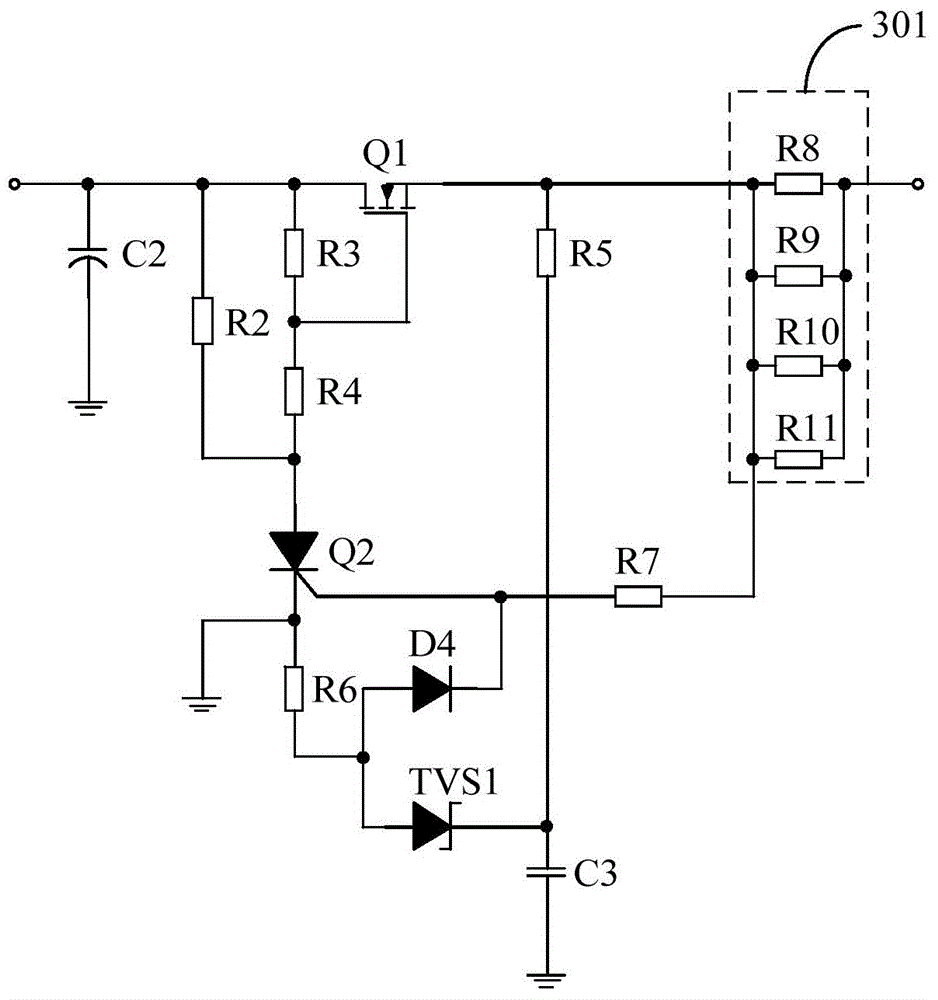

[0053] In this example, if Figure 4 As shown, the current limiting module 20 includes:

[0054] The fifth diode D5, the sixth diode D6 and the twelfth resistor R12;

[0055] The cathode of the fifth diode D5 is connected to the anode of the sixth diode D6, the cathode of the sixth diode D6 is connected to the first end of the twelfth resistor R12, and the input end of the fifth diode D5 is a current limiting module 20 and the second end of the twelfth resistor R12 is the input end of the current limiting module 20 .

[0056] In this embodiment, since the diode is not a reliable component, the resistor is a reliable component. A resistor can be used to replace one of the diodes in the previous embodiment, so that there is a reliable component in the circuit to limit the current. When unreliable components fail, there are reliable components to protect, so as to avoid coal mine fire or explosion.

[0057] Specifically, the twelfth resistor R12 may be a metal film resistor o...

Embodiment 3

[0059] The implementation of this embodiment is based on the foregoing embodiments.

[0060] In this embodiment, the LED driving circuit may further include a seventh diode;

[0061] The cathode of the seventh diode is connected to the positive pole of the storage battery, and the anode is the second positive charging terminal of the LED driving circuit.

[0062] In this embodiment, the battery BAT can be charged through the second positive charging terminal and the negative charging terminal of the LED driving circuit. The added seventh diode can make the LED driving circuit safer during charging, and avoid damage to electronic components inside the LED driving circuit caused by unstable charging current.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com