Low temperature and high humidity thawing method

A low-temperature, high-humidity technology, applied in the direction of freezing/cooling preservation of meat/fish, etc., can solve problems such as increased cleaning costs, loss of protein nutrients in frozen meat, and impact on the sanitation of the thawing warehouse, so as to reduce environmental maintenance costs, Improve the utilization rate of meat and reduce the effect of blood flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the protection scope of the present invention.

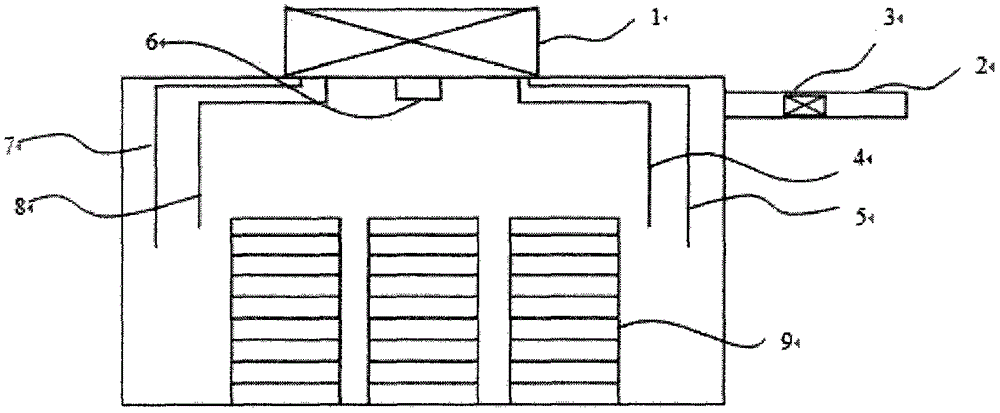

[0018] Such as figure 1 As shown, the present invention is to realize the object of the present invention, the present invention provides a kind of high-humidity low-temperature thawing method, comprises the following steps;

[0019] 1) Steam enters the thawing room, and the fan is turned on at the same time, so that the steam in the thawing room circulates evenly. When the temperature of the thawing room reaches 17-19 ° C, stop entering the steam, and the fan continues to work, so that the thawing room The internal steam is uniform, circulating and flowing, and the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com