Filter element and method for production

A technology for filtering parts and components, applied in chemical instruments and methods, filtration separation, membrane filters, etc., can solve the problems of increasing transportation costs and environmental loads, affecting inventory and transportation costs, and expensive semi-finished products, and reducing transportation costs. and requirements, light weight, to achieve the effect of belt assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Parts of the same or identical type are provided with the same reference symbols in the figures. The drawings show examples only and are not limited to them.

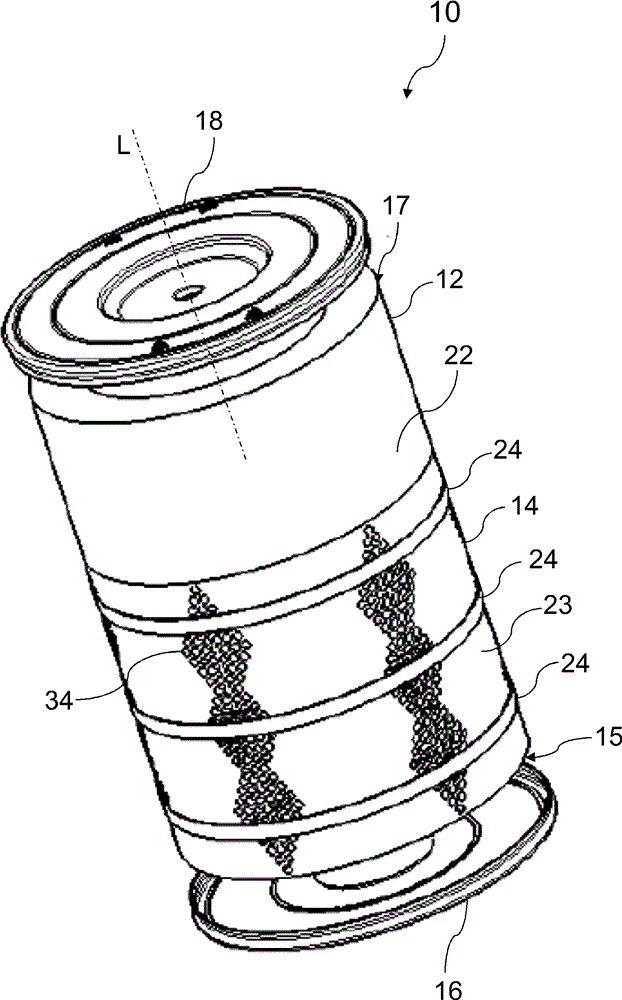

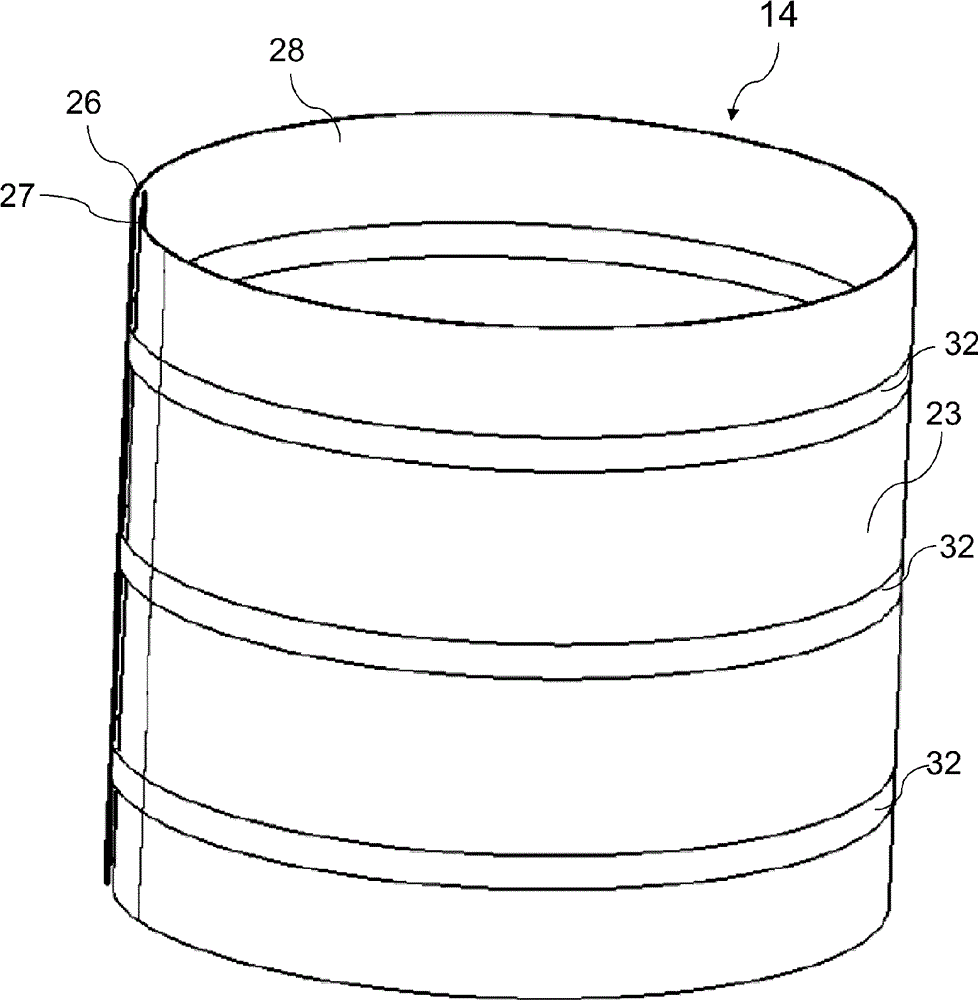

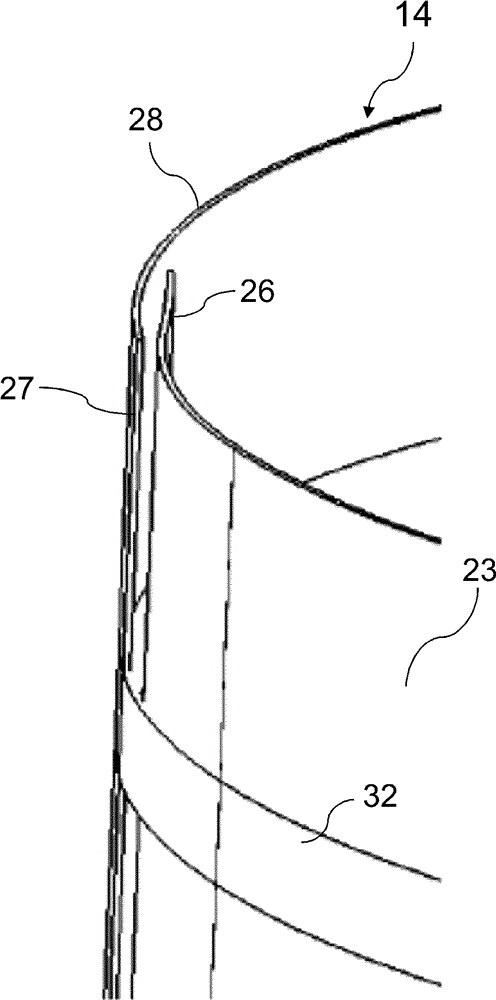

[0038] figure 1 A perspective view of a filter element 10 according to an embodiment of the invention is shown. The filter element 10 comprises a filter body 12 with a longitudinal axis L, a bottom 16 arranged on a first end face 15 of the filter body 12, a cover 18 arranged on a second end face 17 of the filter body 12 and at least a large A housing 14 which surrounds the filter body 12 to a certain extent and has a higher strength than the filter body 12 . Here the housing 14 is on its edges 26, 27 ( image 3 , Figure 4 ,exist figure 1 can not be seen in) is not connected and includes at least one shell part 20, which is laid around the outer circumference 22, in the immediate vicinity of the edges 26, 27 of the housing 14 ( image 3 , Figure 4 ) in which one edge 26 is not connected to the other edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com