Novel concrete mixer

A concrete mixer, a new type of technology, applied in cement mixing devices, clay preparation devices, unloading devices, etc., can solve the problems of difficult to clean, slow discharge, etc., to increase business volume, improve production efficiency, and increase shaking devices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

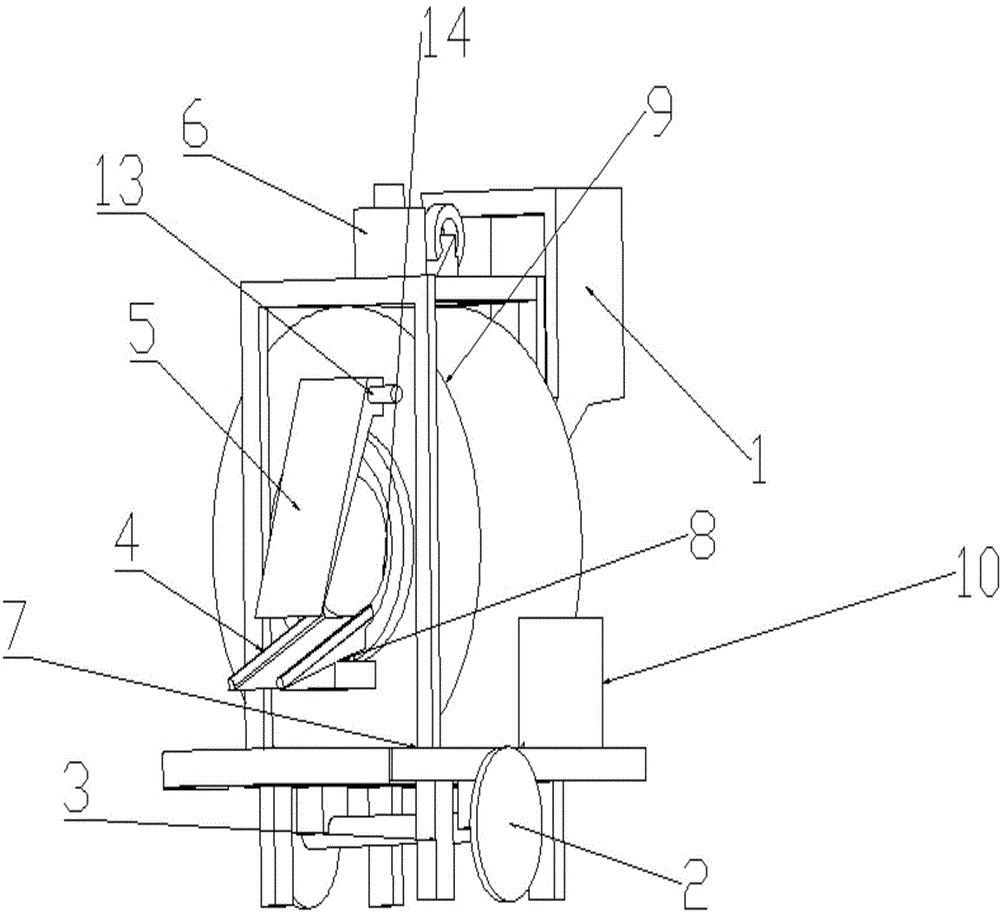

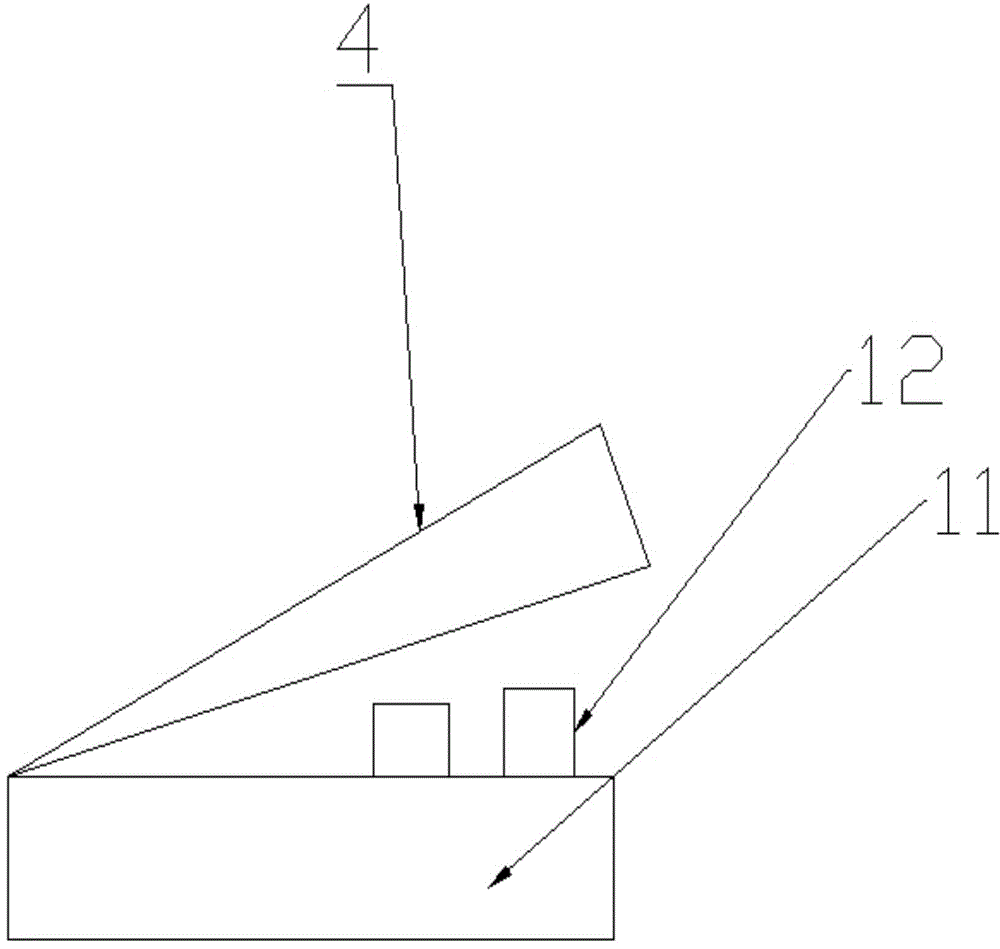

[0017] A new type of concrete mixer, including wheels (2), upper hopper (1), chute (4), baffle plate (5), mixing drum (9), power system (10); mixing drum (9) has a mixing drum inlet (14), mixing drum outlet; mixing drum inlet (14) connected to the hopper (1); mixing drum outlet (14) has a chute (4), shielding baffle (5); chute (4) at the mixing drum outlet (14) The lower end of the shielding plate (5) is at the upper end of the mixing drum outlet (14); the lower end of the chute (4) has a shaking device (8); the shielding plate (5) is connected to the mixing drum (9) through the vertical rotating shaft (13); The length of the shielding plate (5) is equal to the distance from the vertical rotating shaft (13) to the lower end of the mixing drum outlet (14); the width of the shielding plate (5) is not less than the diameter of the mixing drum outlet (14); the shaking device (8) includes a fixed power table (11) ), the shaking column (12); the shaking column (12) is set on the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com