Injection mold of composite core-pulling mechanism

A core-pulling mechanism and injection mold technology, which is applied in the field of injection molds of composite core-pulling mechanisms, can solve problems such as the inability to meet the precision and appearance requirements of plastic parts, and achieve the effects of reliable structure, high mold clamping accuracy, and meeting production needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

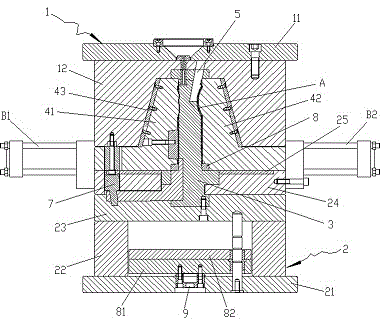

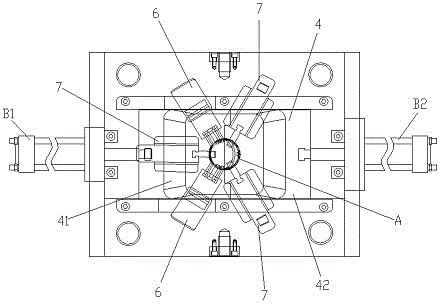

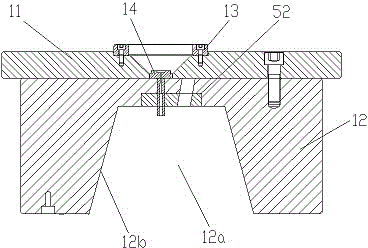

[0024] Figure 1 to Figure 7 It is a structural schematic diagram of the present invention.

[0025] The reference signs are: injection molding product A, left core-pulling cylinder B1, right core-pulling cylinder B2, fixed mold group 1, fixed mold fixed plate 11, fixed mold plate 12, fixed mold lock cavity 12a, inner slope 12b, positioning ring 13. Nozzle 14, moving mold group 2, rear mold seat plate 21, mold foot 22, moving mold fixing plate 23, moving mold plate 24, moving mold wear-resistant plate 25, moving mold core 3, large slider 4, left half Slider 41, right half slider 42, slider wear-resistant plate 43, upward core-pulling mechanism 5, upward slider 51, row guide block 52, decorative hole core-pulling mechanism 6, decorative hole slider 61, decorative Hole shovel 62, slider core-pulling mechanism 7, lower buckle slider 71, slider g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com