Deformation device of crawler belt running system

A deformation device and crawler technology, applied to tracked vehicles, transportation and packaging, motor vehicles, etc., can solve the problems of tracked vehicles such as reduced ground area, easy slipping, sinking, and good cross-ditch performance, and achieve driving ability and anti-sinking Effects of ability enhancement, overcoming driving ability and passability, and expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

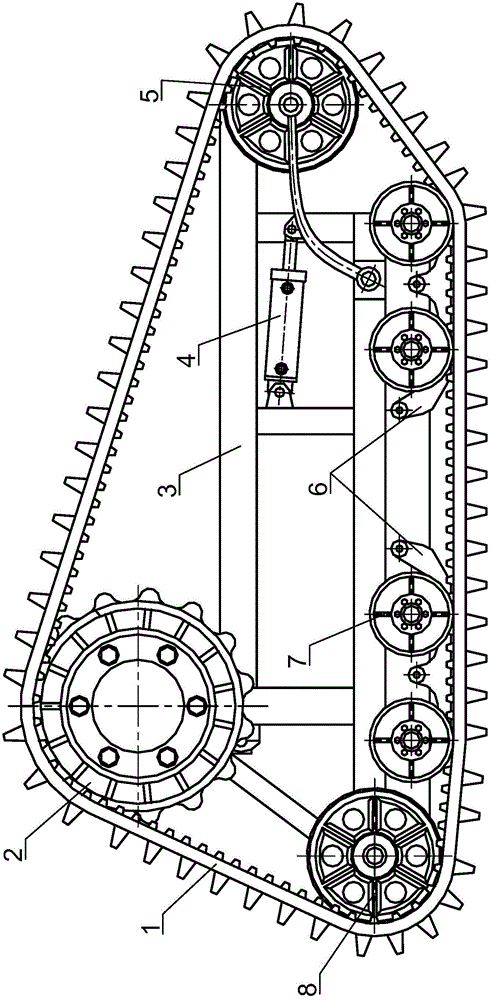

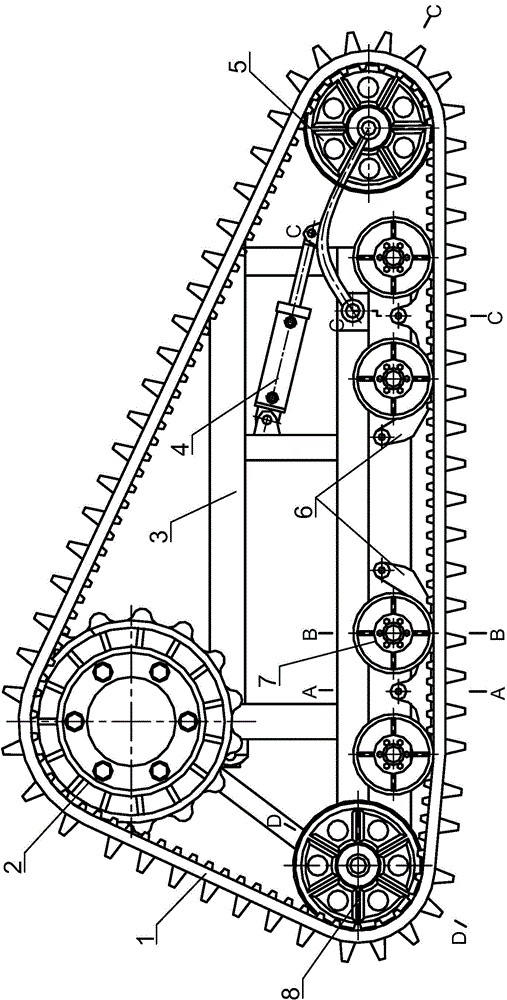

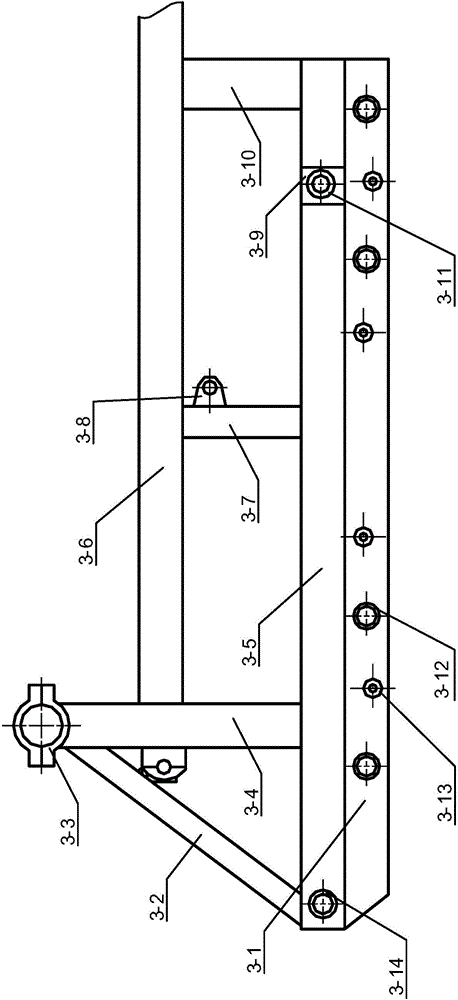

[0025] see Figure 1 to Figure 9 A deformation device for a crawler driving system, comprising a crawler 1, a drive wheel 2, a vehicle frame 3, a hydraulic cylinder 4, a front support wheel 5, an inner guide plate 6, a load-bearing wheel 7, a rear support wheel 8, a crawler main body 1-1, Drive groove 1-2, limit tooth 1-3, drive tooth 1-4, bottom frame 3-1, inclined connecting rod 3-2, driving wheel bushing 3-3, rear connecting rod 3-4, bottom frame reinforcement frame 3-5, upper frame 3-6, middle connecting rod 3-7, hydraulic cylinder connecting seat 3-8, front supporting wheel connecting pin 3-9, front connecting rod 3-10, front supporting wheel connecting pin bracket 3- 11. Bearing wheel support pin 3-12, inner guide plate support pin 3-13, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap