Connection method of concrete precast pile and pile foundation cap

A technology of prefabricated concrete piles and connection method, which is applied in basic structure engineering, construction and other directions, can solve problems such as construction troublesome core-filling concrete construction quality is difficult to control, core-filling concrete affects pull-out quality, and inner wall mud cannot be cleaned up, etc. The effect of saving comprehensive cost, avoiding engineering safety accidents, and increasing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

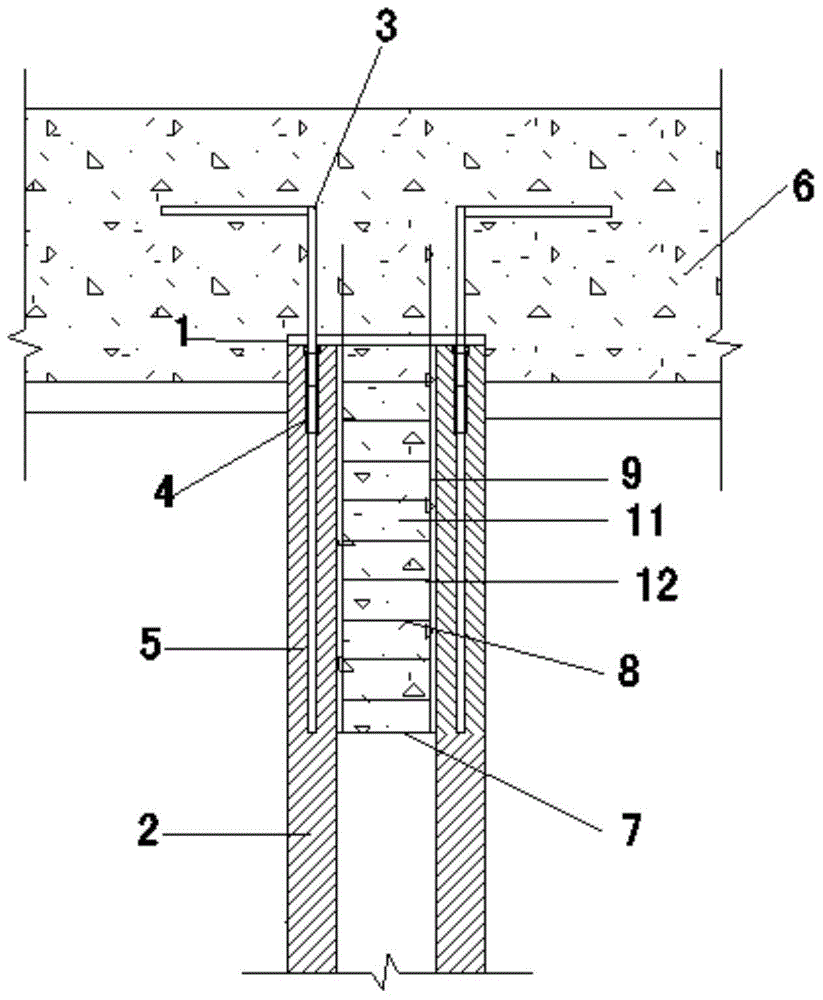

[0025] Example 1, when the concrete prefabricated pile 2 is a solid pile, take a concrete prefabricated pile 2 with a diameter of 500 mm and a wall thickness of 125 mm, and pre-embed a plurality of lower threaded steel bars 5 in the concrete precast pile 2 in advance, and the lower threaded steel bars 5 are HRB400 The number of hot-rolled ribbed steel bars is preferably 8, the diameter of which is 22mm, the total length is 600mm, and the tapping length of the upper end is 100mm. The sleeve 4 is a full internal tooth structure with a length of 200mm, an outer diameter of 30mm and an inner diameter of 20mm. The upper thread teeth of each lower threaded steel bar 5 are all mechanically connected with the sleeve 4 .

[0026] Then the upper threaded steel bar 3 arranged in the pile cap 6 is tapped and connected to the sleeve 4 . Wherein, the upper threaded steel bar 3 is HRB400 hot-rolled ribbed steel bar, the number is preferably 8, its diameter is 22mm, the total length is 600mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com