A contactless electromagnetic clutch

An electromagnetic clutch, non-contact technology, applied in the direction of magnetic drive clutches, clutches, non-mechanical drive clutches, etc., can solve problems such as wear and tear, achieve the effects of expanding the scope of use, improving service life, and overcoming mechanical contact wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

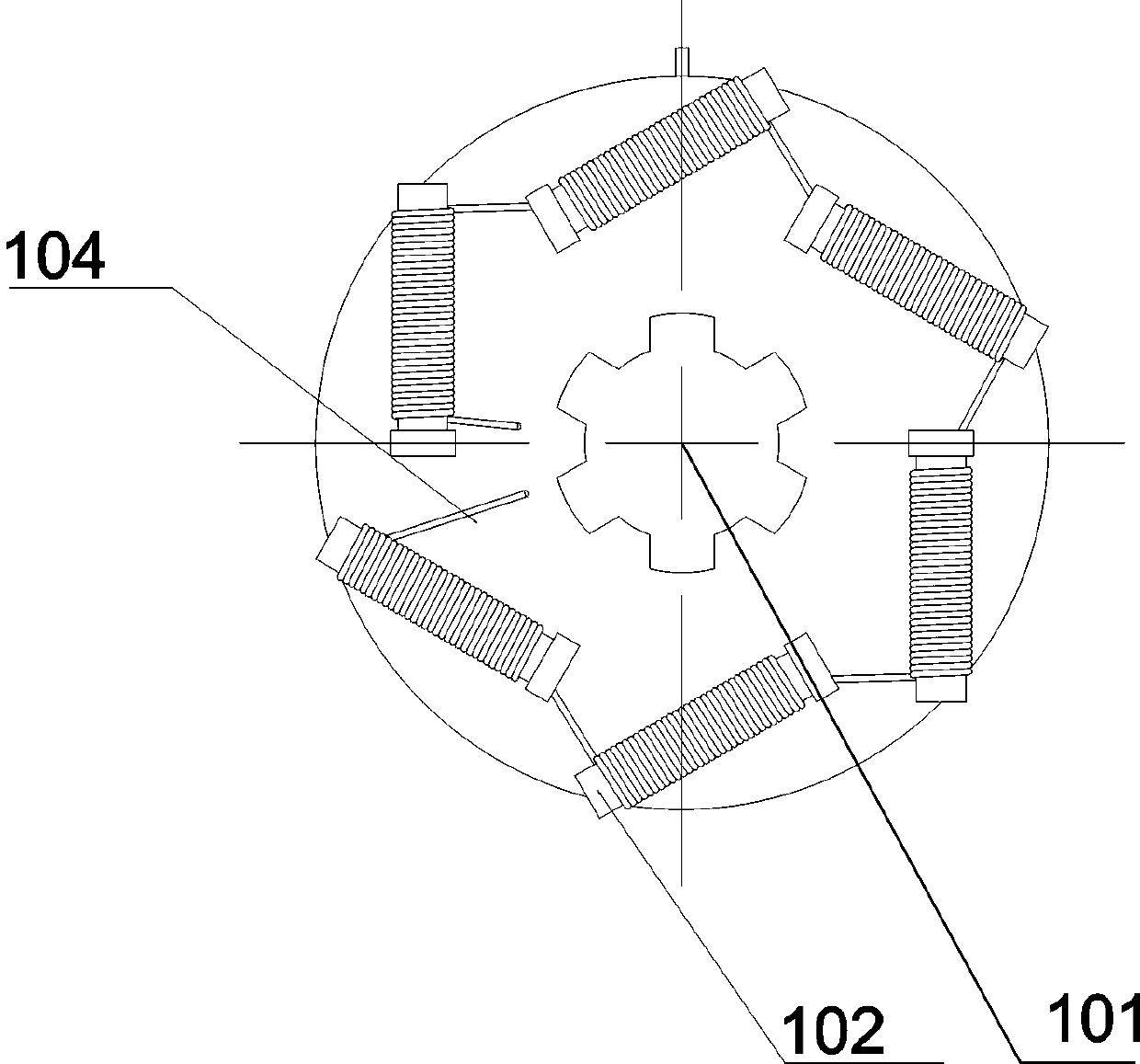

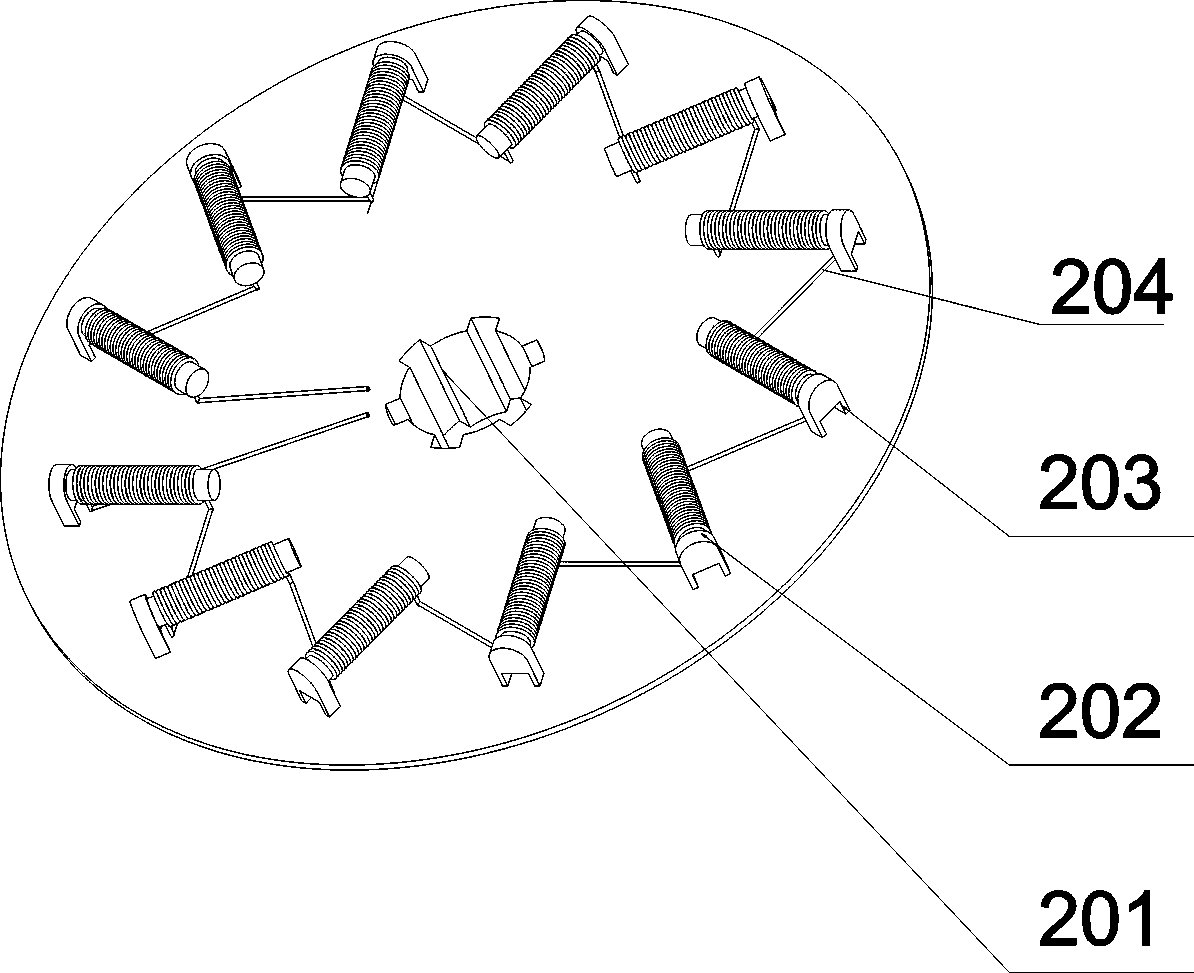

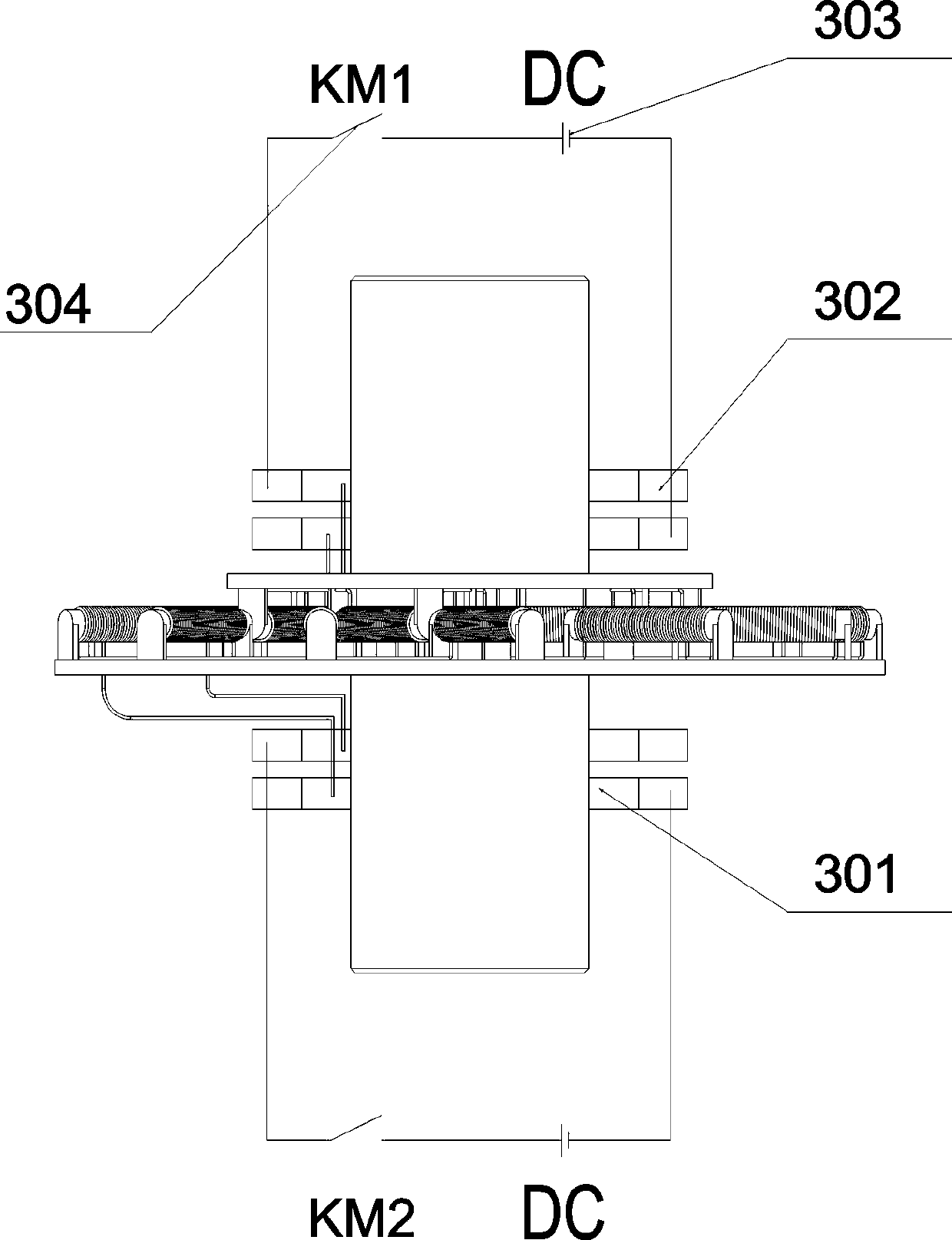

[0027] Such as Figure 1~Figure 5 As shown, a non-contact electromagnetic clutch includes a driving part 1, a driven part 2, and a brush power supply part 3. The active part 1 includes a power shaft connection plate 101 connected to the prime mover shaft, a first iron core 102 and a first wire 104 . The driven part 2 includes a drive shaft connection plate 201 connected to the drive shaft, a second iron core 202 and a second wire 204 .

[0028] The brush power supply part 3 includes a dynamic brush 301 fixedly connected to the power shaft connection plate 101, the dynamic brush 301 is in contact with a fixedly installed electrostatic brush 302, the electrostatic brush 302 is connected to an external power supply 303, and the current is transmitted through the electrostatic brush 302 to the moving brush 301.

[0029] A plurality of first iron cores 102 are fixedly installed on the power shaft connection plate 101, and a first wire 104 is wound on the plurality of first iron c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com