Composite spring structure realizing equal offset frequency of variable stiffness

A variable stiffness and offset frequency technology, applied in the field of offset frequency composite spring structure, can solve the problems of large unsprung mass of rear suspension, sudden change of offset frequency, difficult quality control, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

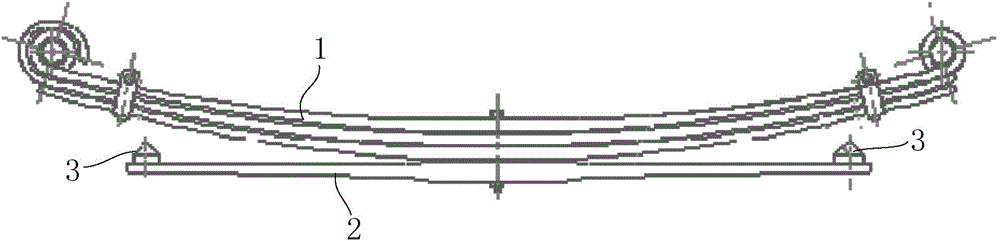

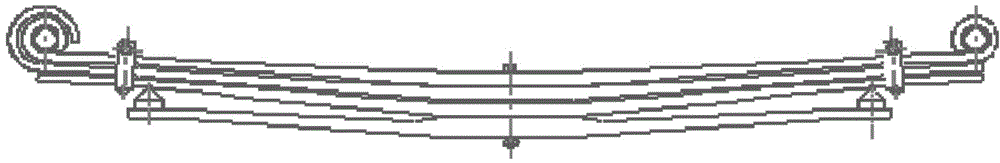

[0021] like figure 1 , figure 2 and image 3 As shown, a compound spring structure with variable stiffness and equal frequency bias includes a main spring 1, an auxiliary spring 2 and a buffer block 3, the two ends of the main spring 1 are bent upwards, and the middle part is connected with the auxiliary spring 2, and the buffer block 3. Set the two ends of the auxiliary spring 2. The buffer block 3 is preferably a rubber buffer block.

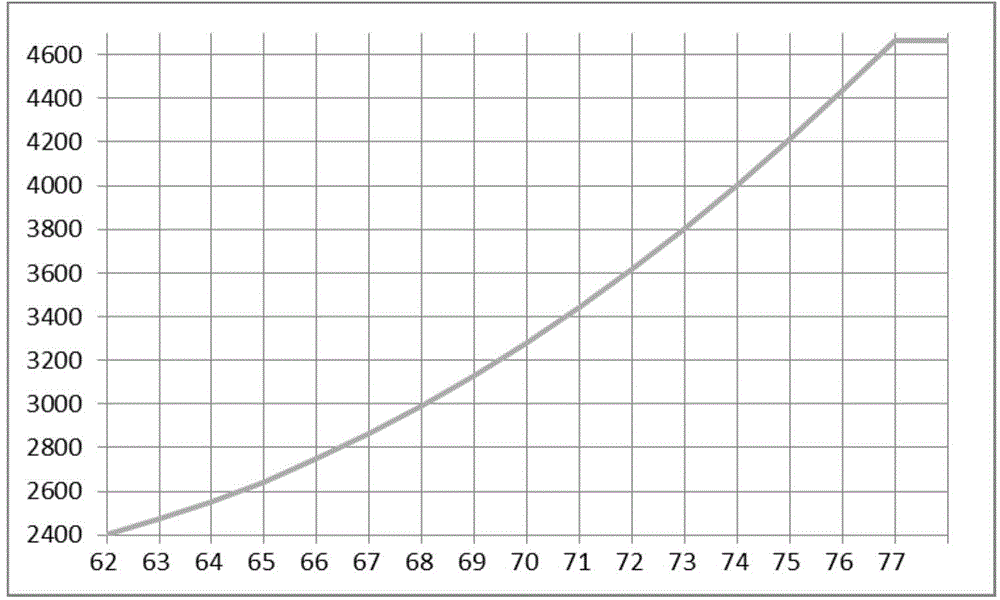

[0022] figure 1 The middle composite spring assembly is in a free state; figure 2 When the middle composite spring is in the empty condition, the main spring 1 and the auxiliary spring 2 start to contact; image 3 When the middle composite spring is fully loaded, the main spring 1 is fully in contact with the auxiliary spring 2, the buffer block 3 is compressed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com