Leakage-proof pipeline connecting device

A connection device, anti-leakage technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of uneven glue coating, imperceptible water leakage, decoration loss, etc., to achieve installation. Simple, reliable installation and tightening, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

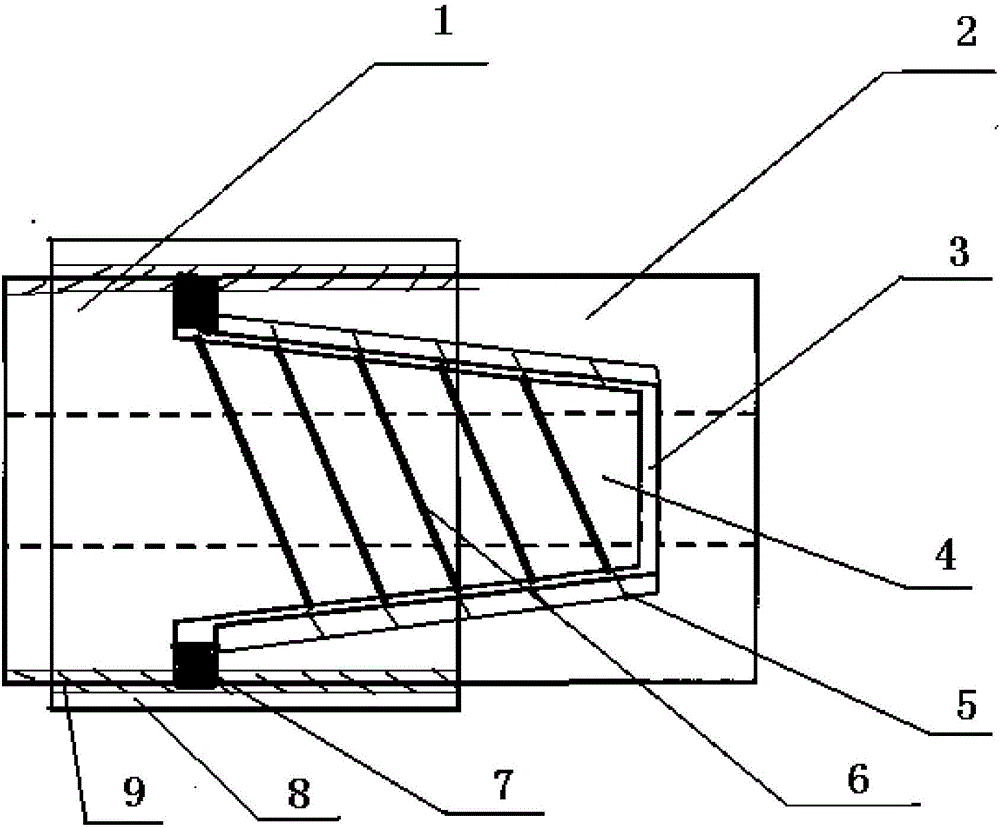

[0022] Such as figure 1 , an anti-leakage pipeline connection device, including a male connector 1 and a female connector 2, the male connector 2 and the female connector 2 are respectively connected to the pipeline externally, and the male connector 1 is provided with a boss 4 , the female connector 2 is provided with a concave cavity 3, the shape of the boss 4 and the concave cavity 3 are matched, the outer surface of the boss 4 is provided with a boss thread 6, and the interior of the concave cavity 3 is set There is a concave cavity thread 5, and the boss thread 6 and the so-called concave cavity thread 5 can be matched and rotatably connected, and the boss thread 6 and the so-called concave cavity thread 5 are double-thread structures. The double-thread structure achieves the effect of tight rotation and no disengagement.

[0023] The simple struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com