Ruled surface adaptively measuring method based on constant contact force

A measurement method and contact force technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of many measuring points and slow measuring speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

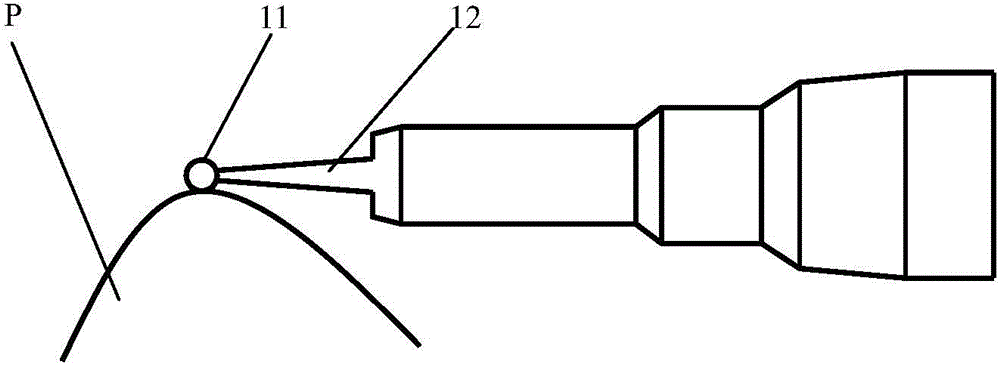

[0036] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

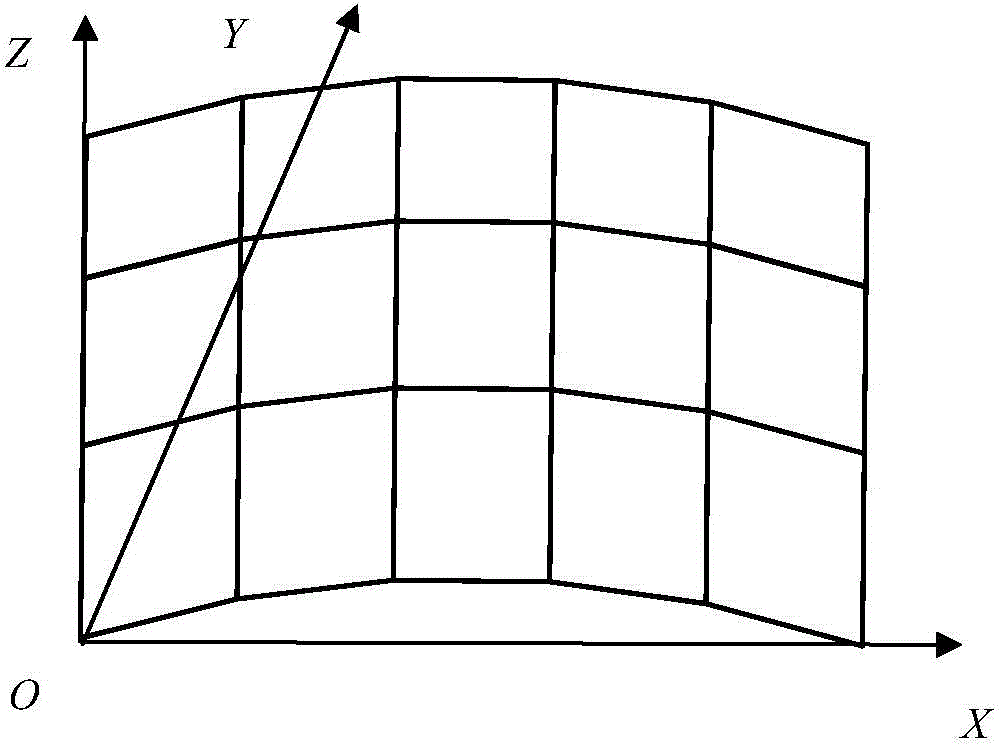

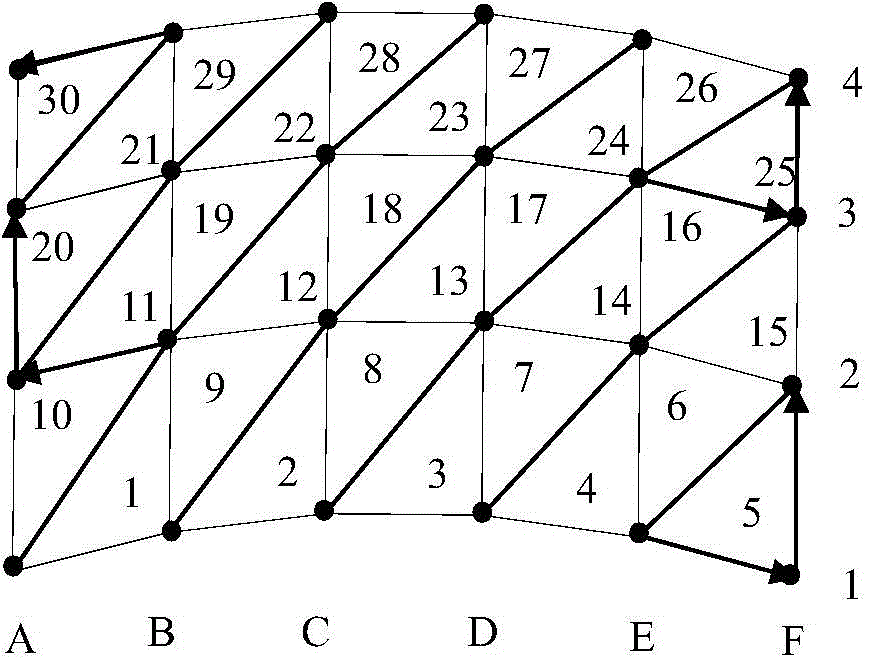

[0037] see Figure 2~4 , the embodiment of the present invention includes the following steps:

[0038] 1) Divide the measured surface into grids at equal intervals in the x and z directions;

[0039] 2) Move the probe to the initial position of the surface part to be tested (see image 3 point A1);

[0040] 3) Apply a small displacement along the normal direction of the measured surface, and obtain the contact force through the probe stiffness and displacement. The specific algorithm is:

[0041] f y =(y 1 -y 0 )×k y

[0042] Among them, F y is the component of the contact force between the probe and the measured surface in the direction of the coordinate axis y-axis. k y is the stiffness of the probe in the y direction of the measurement coordinate system; y 0 is the y-axis coordinate value of the initial position of the probe; y 1 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com