Method for adjusting hot-spot temperature on-line monitoring of transformer winding

A technology of transformer winding and hot spot temperature, which is applied to thermometers, thermometers, instruments, etc. that change physically/chemically, and can solve problems such as difficulty in determining the location of hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

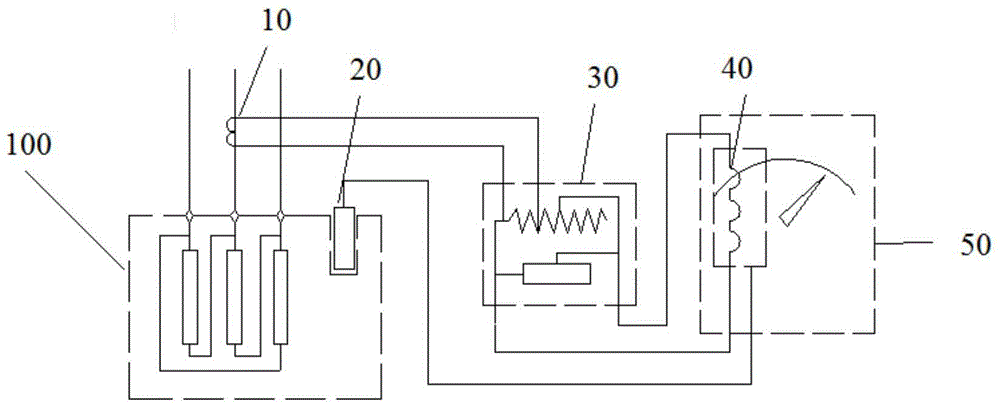

[0027] The specific embodiment of the present invention provides a method for adjusting the online monitoring of transformer winding hot spot temperature (hereinafter referred to as the adjustment method), which is used in the field of transformer winding temperature monitoring, such as Figure 4 As shown, the adjustment method includes the following steps S1-S4:

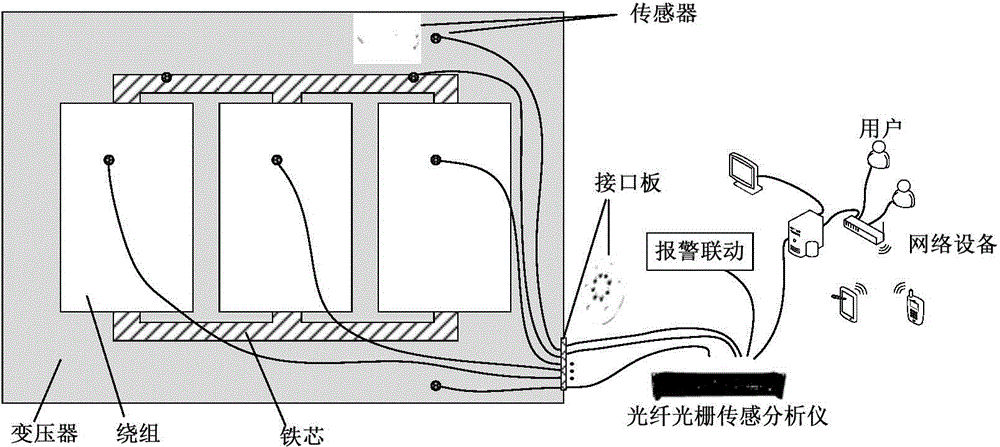

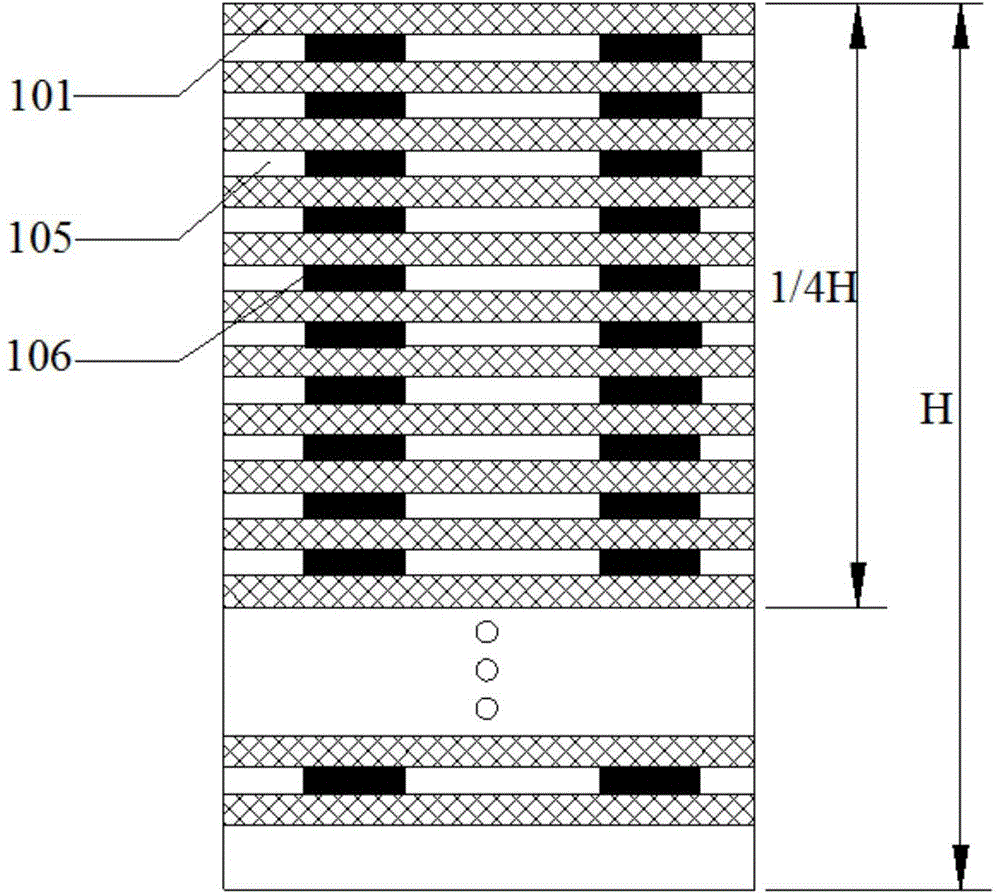

[0028] S1. Obtain the first hot spot temperature of the winding by direct temperature measurement with optical fiber, and obtain the second hot spot temperature of the winding by thermal simulation. Specifically, the optical fiber direct temperature measurement method can refer to figure 2 , the optical fiber sensor 200 is set at different positions in the winding of the transformer 100. Generally, the transformer has three phases, so there are at least three windings, for example ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap