Detecting cart of iron core fault of handhold type generator

A fault detection and generator technology, applied in the fault location, measurement power, measurement device and other directions, can solve the problems of accurate determination affecting detection, asynchronous detection and judgment, inconvenient carrying and detection, etc., to facilitate detection and reduce operation. The effect of personnel burden, easy to detect and locate fault points in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

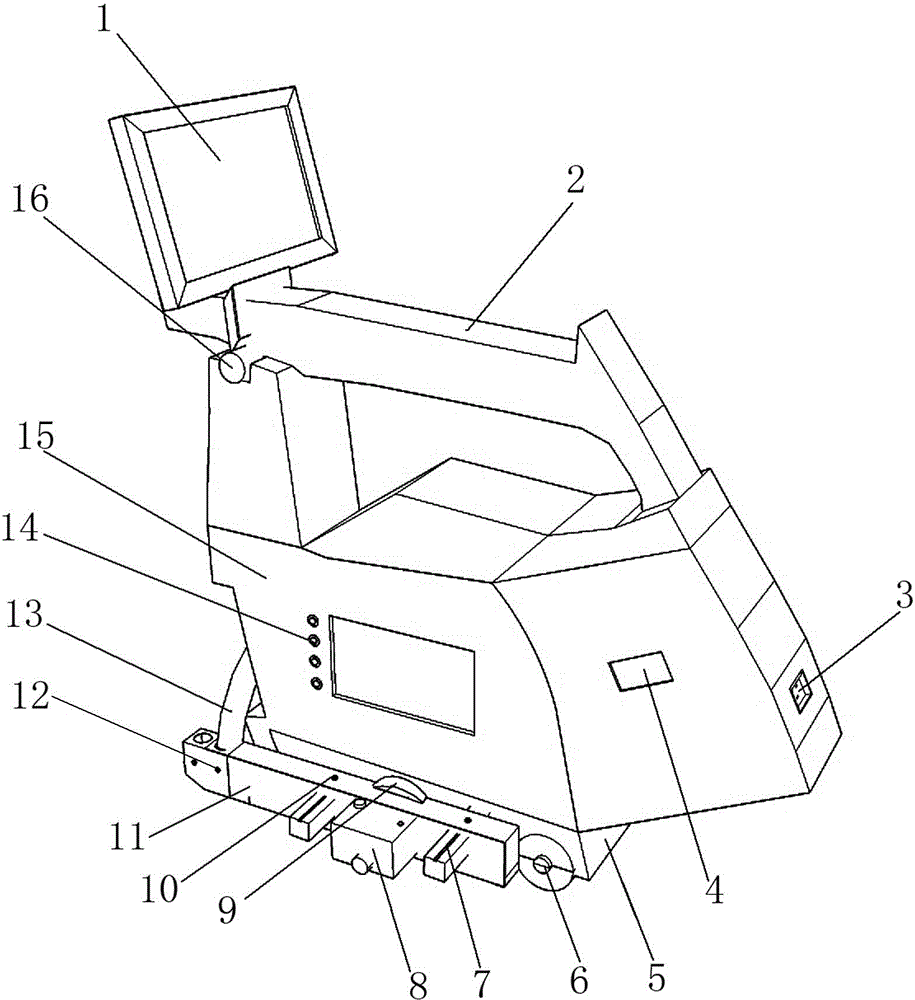

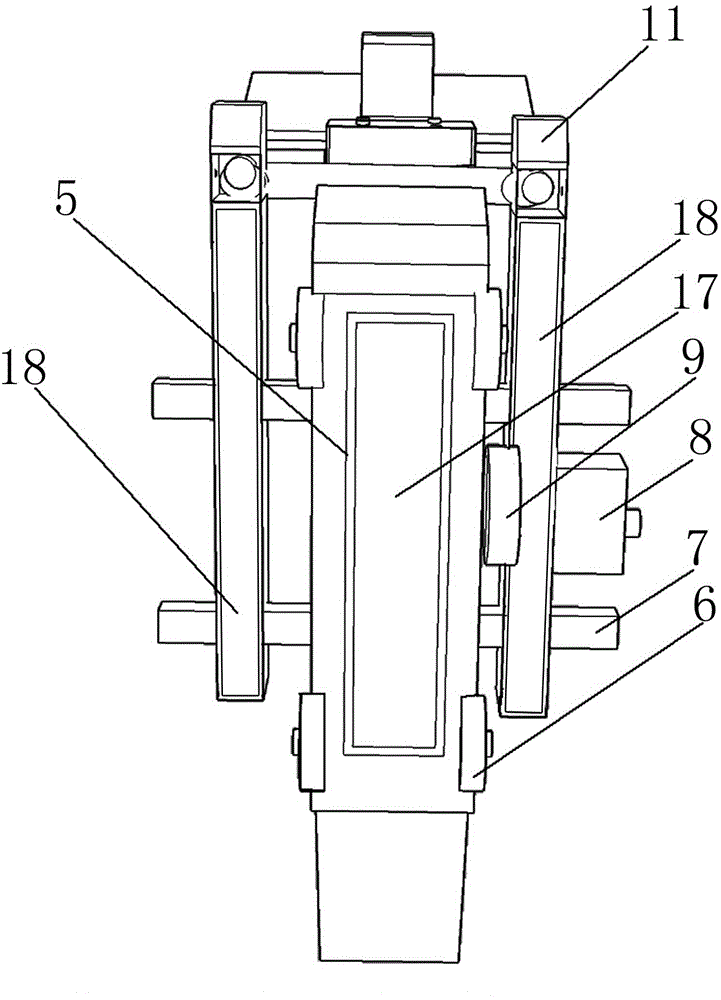

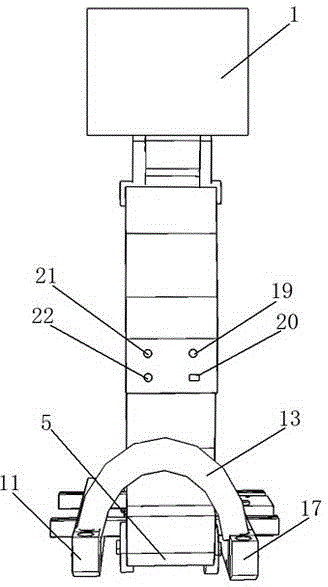

[0018] Depend on Figure 1-3 As can be seen from the illustrated embodiment, it includes a detection coil 13, a displacement sensor 8, a phase sensor 23, a single-chip microcomputer and a display screen 1; The chassis 5 on the bottom surface, a pair of detection coil fixed cross bars 11 and the wheels 6 installed on the chassis 5; a pair of frame width adjustment rods 7 are symmetrically installed on the left and right sides of the chassis 5, and the chassis 5 A pair of vehicle frame width adjusting rods 7 on the left and right sides are respectively inserted into the jacks of the corresponding detection coil fixing cross bars 11, and fixed by the first fixing screws 10; the two ends of the detection coil 13 are respectively inserted into a pair of The detection coil is fixed in the detection coil jack in front of the cross bar 11, and is fixed by the second fixing screw 12; the displacement sensor 8 is fixed on the detection coil fixing cross bar 11 on one side; the phase sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com