Design method of composite material laminates with equal thickness

A technology of composite materials and design methods, applied in computing, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

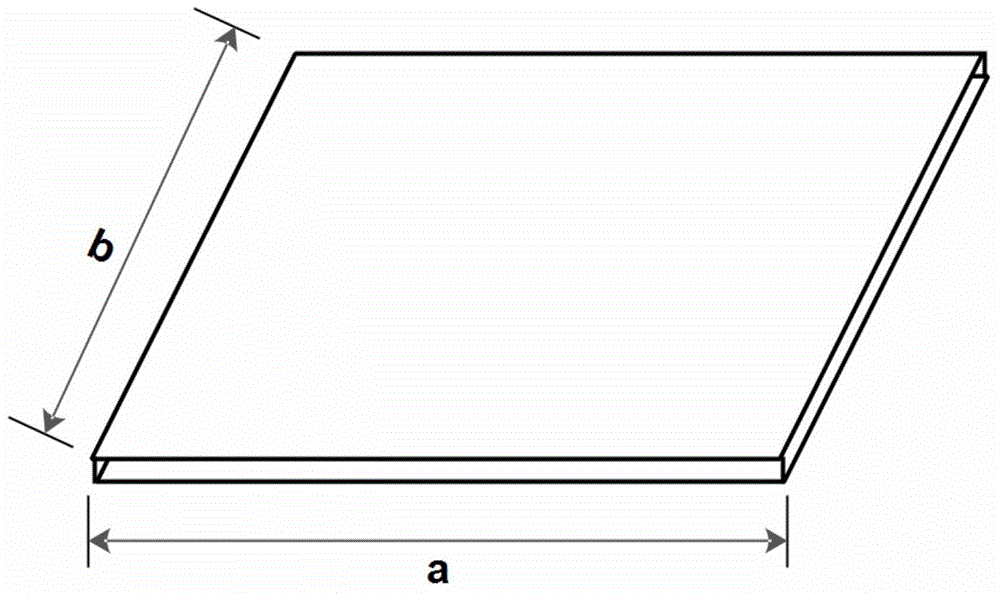

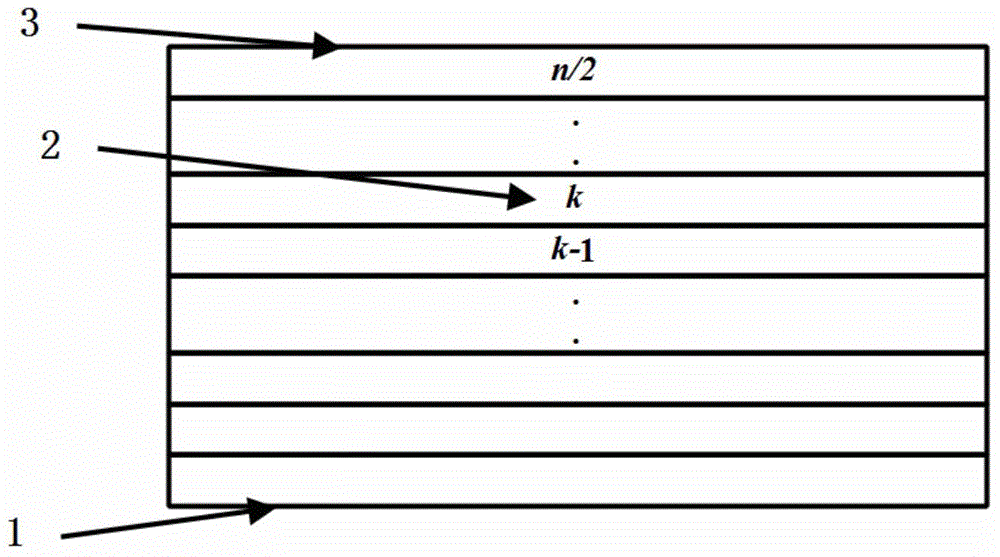

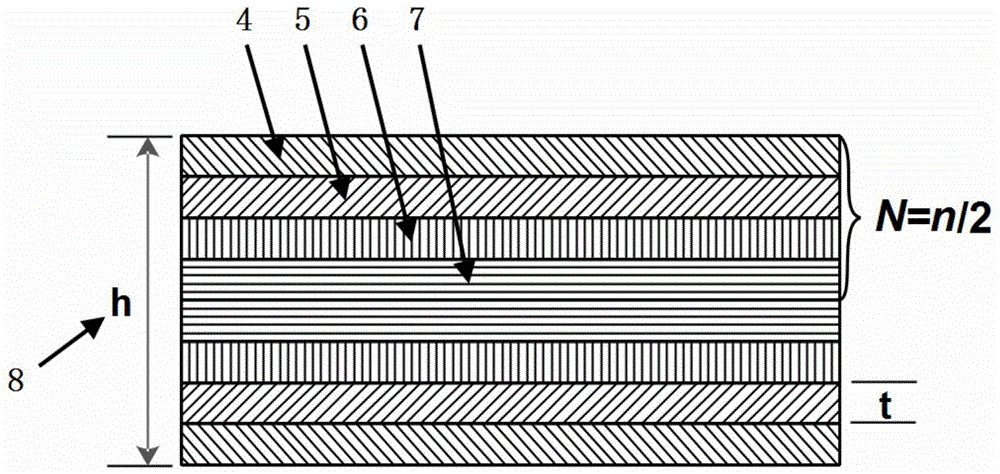

[0052] In order to make the ply optimization design of composite laminates practically applicable to engineering practice, this embodiment proposes a design method for the ply sequence of equal-thickness plywood.

[0053] In this embodiment, using the theoretical formula of composite material mechanics, the bending stiffness coefficient is deduced to be a discrete function form of the sum of the bending stiffness coefficient components at each ply position. And the bending stiffness coefficient component function is a transcendental function about the position and the orientation angle of the position. Then, in the performance optimization of the first stage, the initial ply group sequence of the laminate was set, and the ply group sequence is the ply sequence in which the plies of each laying angle are placed together consecutively. According to the performance optimization of the first stage, the continuous variable thickness of each laying corner layer group was obtained, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com