Air duct cooling system for vehicle battery pack

A vehicle-mounted battery pack and cooling system technology, which is applied in the field of vehicle-mounted battery pack air duct cooling system, can solve problems such as the failure of the battery pack cooling device, and achieve the effect of improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

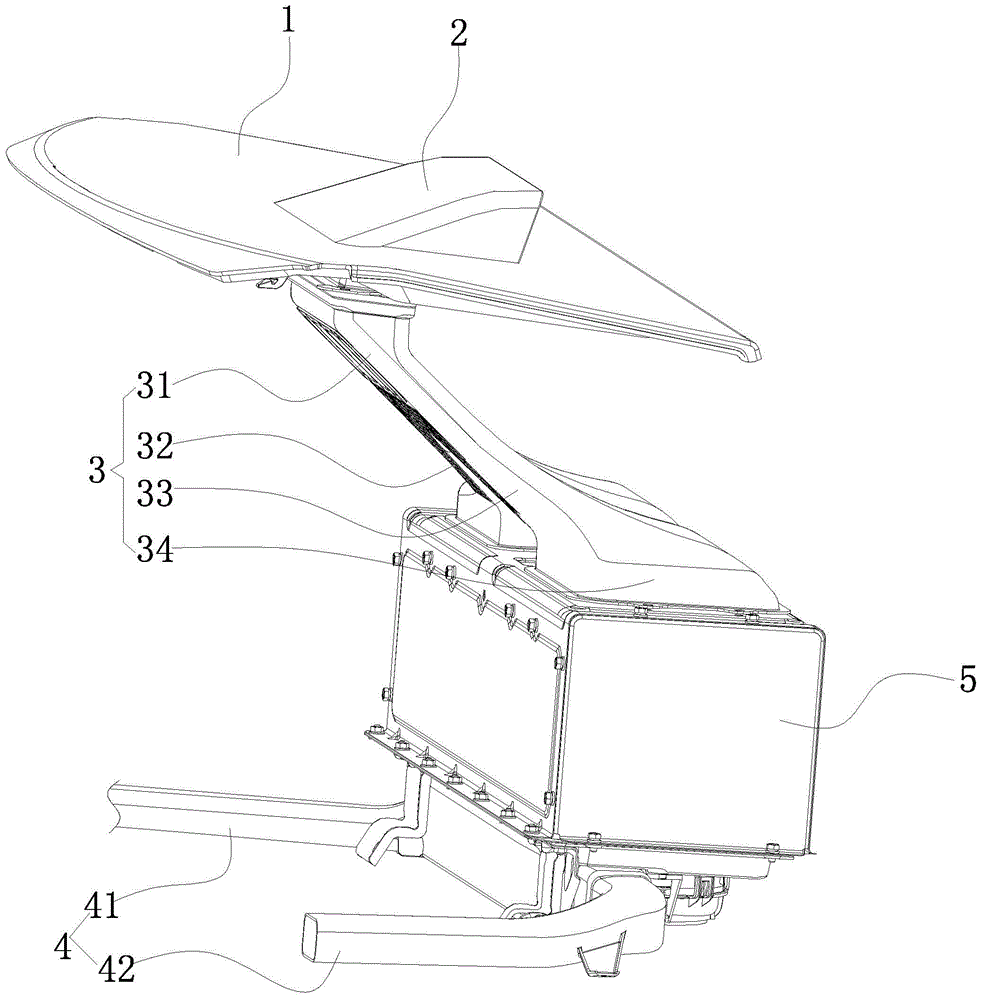

[0025] Embodiment 1: as figure 1 As shown, a vehicle-mounted battery pack air duct cooling system includes a battery pack case 5 , an air intake duct 3 and an exhaust duct 4 . The trunk partition 1 is provided with an air inlet (the trunk partition refers to the trunk partition between the rear windshield of the car and the adjacent rear seats). A wind guide cover 2 with an opening facing the front of the car is arranged on the trunk partition of the car and is located directly above the air inlet. An upper vent is provided on the top surface of the battery pack housing. The upper vent consists of left and right upper vents. A lower vent is provided on the bottom surface of the battery pack shell. The lower vent consists of left and right lower vents.

[0026] The air intake duct is located under the trunk partition of the car. The air inlet duct is Y-shaped, and it is composed of a main air inlet pipe 31 and left and right branch air inlet pipes 32, 33 communicated with ...

Embodiment 2

[0029] Embodiment 2: the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

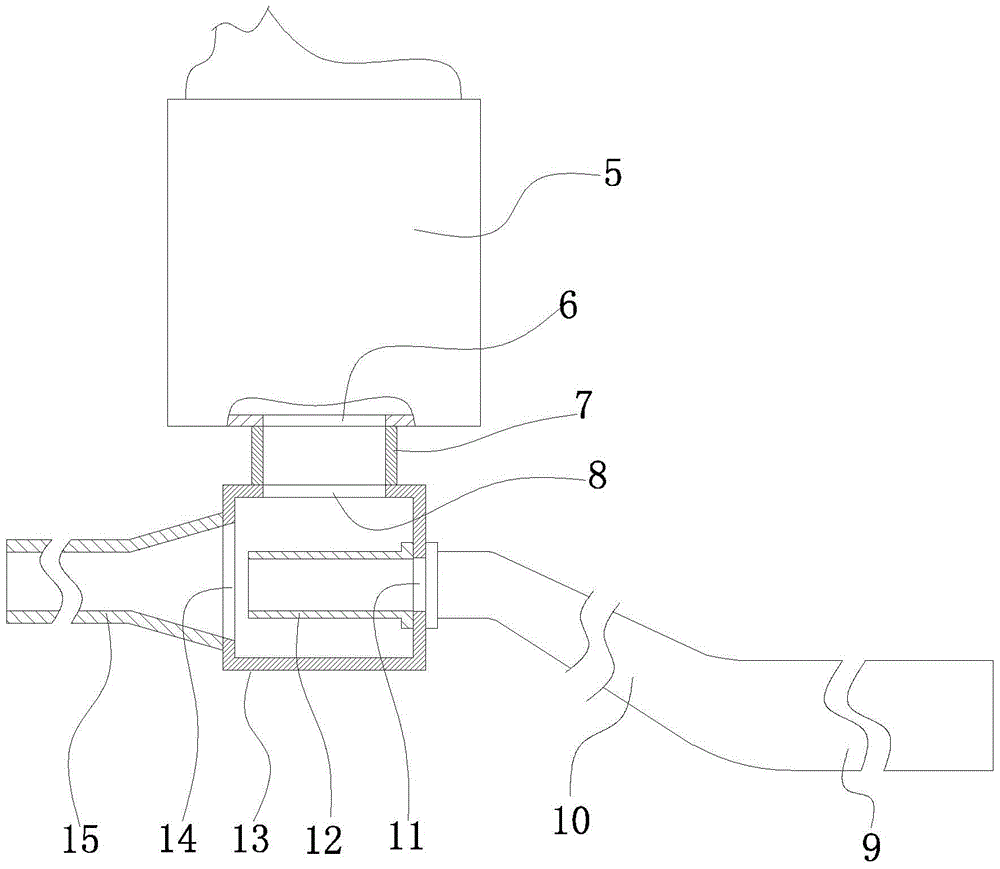

[0030] Such as figure 2 As shown, a vehicle-mounted battery pack air duct cooling system also includes a guide duct 9 , an air outlet duct 15 and a negative pressure suction container 13 . An air outlet 6 is also provided on the bottom surface of the battery pack casing. The air exhaust port communicates with the inner cavity of the battery pack housing. The negative pressure suction container is located below the battery pack housing, and a ventilation hole 8 is arranged on the top surface of the negative pressure suction container. An air inlet 11 and an exhaust hole 14 are also provided on the side of the negative pressure suction container, and the air inlet and the exhaust hole are located on opposite side surfaces of the suction container. The suction container is provided with an air jet pipe 12 extending from the air intake hole to the exhaust h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com