Feeding device for motor rotor magnetic shoe filling

A motor rotor and magnetic tile technology, applied in the field of rotor manufacturing equipment, can solve the problems of low feeding efficiency, falling off and jamming the motor, affecting processing efficiency, etc., and achieve the effect of improving work efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

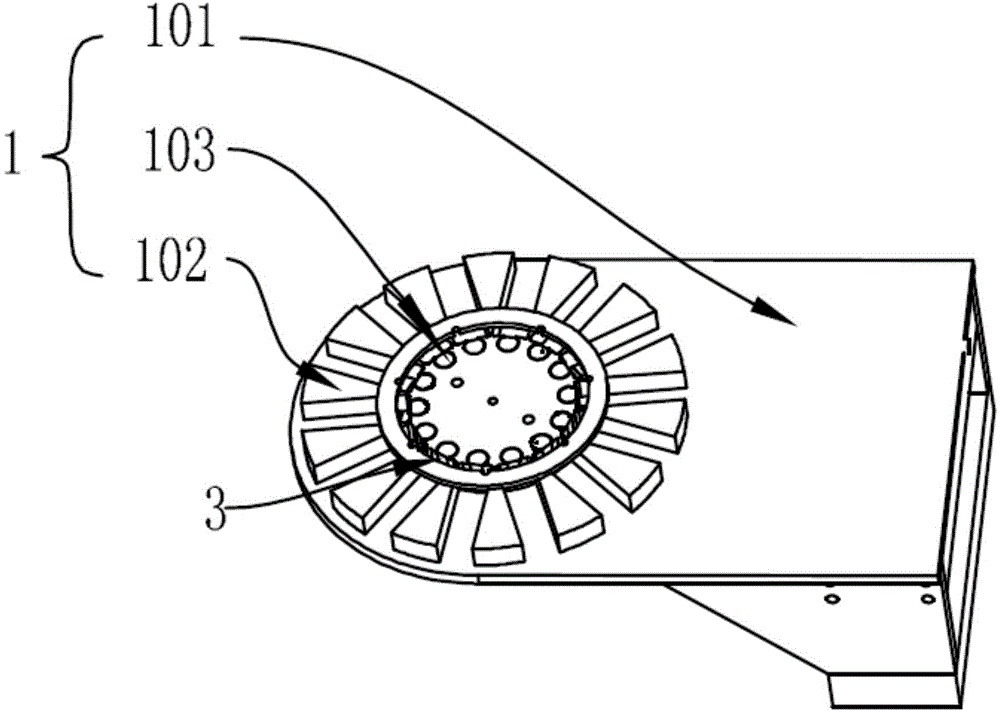

[0024] Such as figure 1 As shown in , a feeding device for filling magnetic tiles of motor rotors;

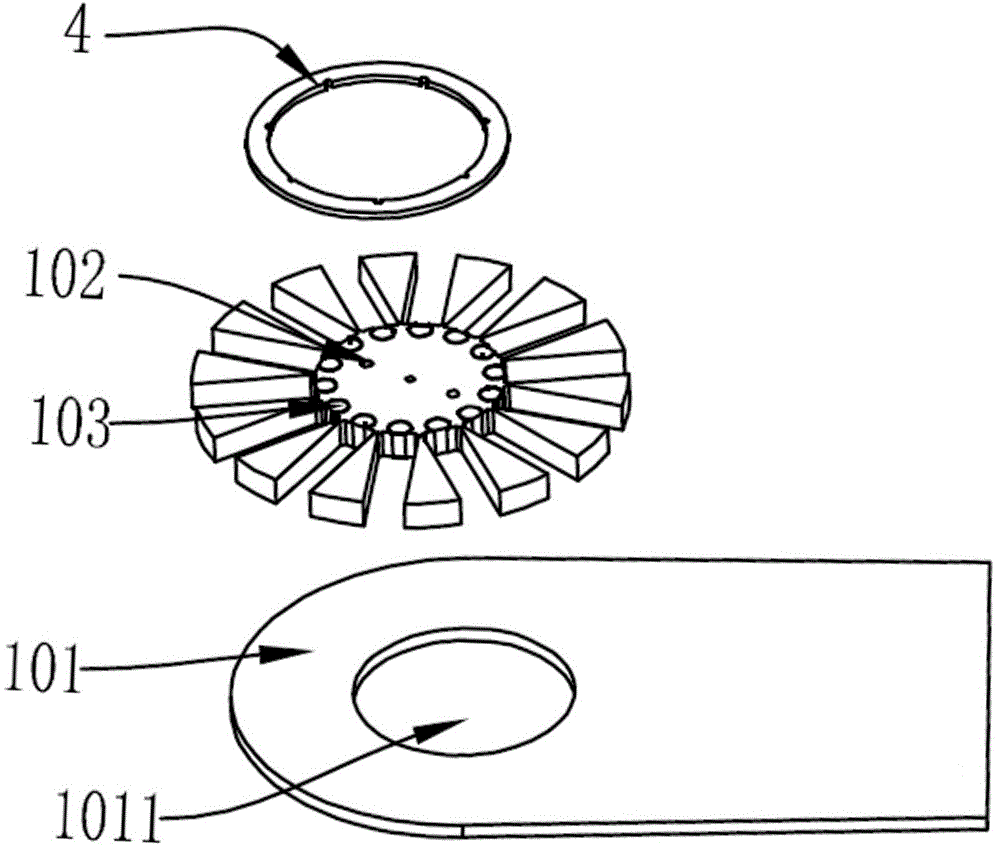

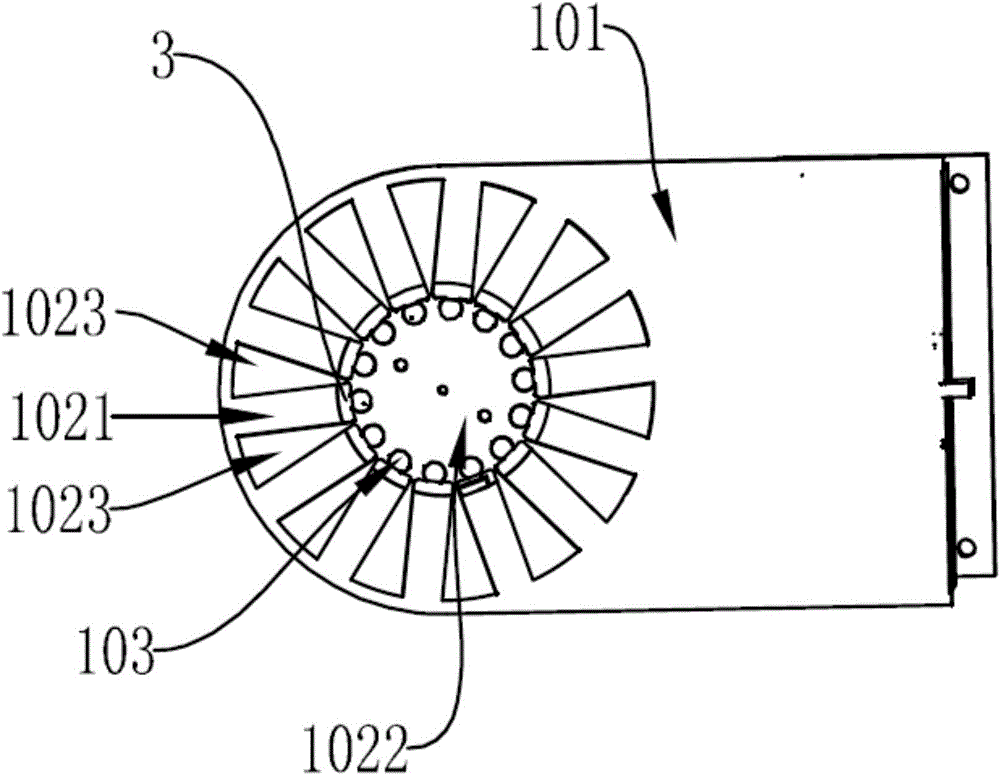

[0025] Such as figure 2 and image 3 As shown, it includes a supporting plate 101, a magnetic tile channel plate 102 and a magnet 103. The magnetic tile channel plate 102 is provided with several storage channels 1021 for placing magnetic tiles; the magnetic tile channel plate 102 is arranged on the support The upper end surface of the plate 101, the supporting plate 101 is provided with a blanking channel 1011 communicating with one end of the storage channel 1021 to form a magnetic tile blanking opening 3 corresponding to the arrangement position of each magnetic tile in the motor rotor ; The magnet 103 is located at the magnetic tile blanking port 3 for absorbing the magnetic tile placed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com