Universal bottle stopper

A bottle stopper and outer shell technology, applied in the direction of expandable sealing parts, etc., can solve problems such as affecting the quality of the objects in the bottle, difficult to ensure the sealing effect of the bottle mouth, and loss of sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

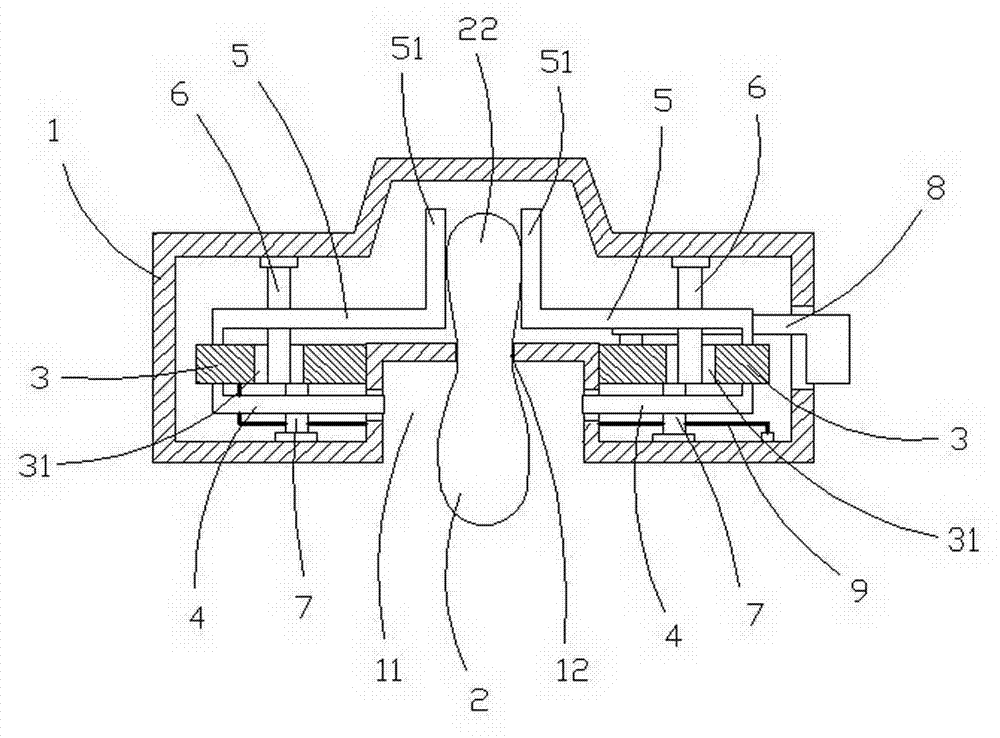

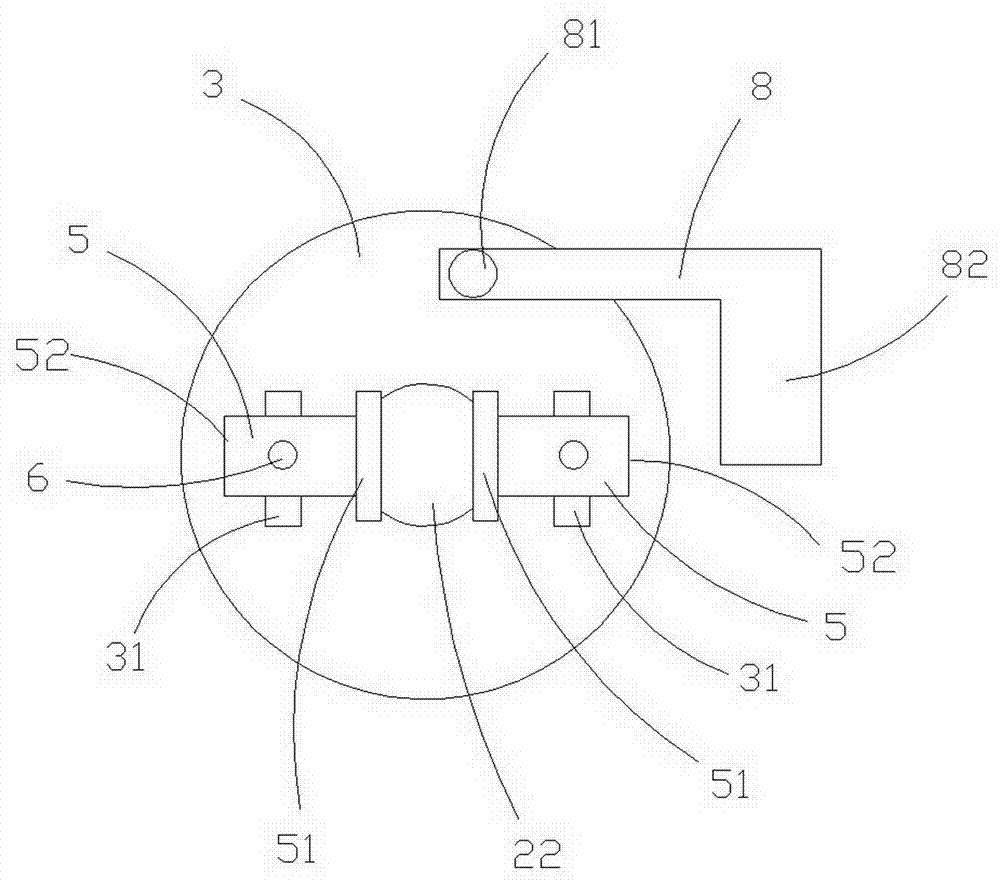

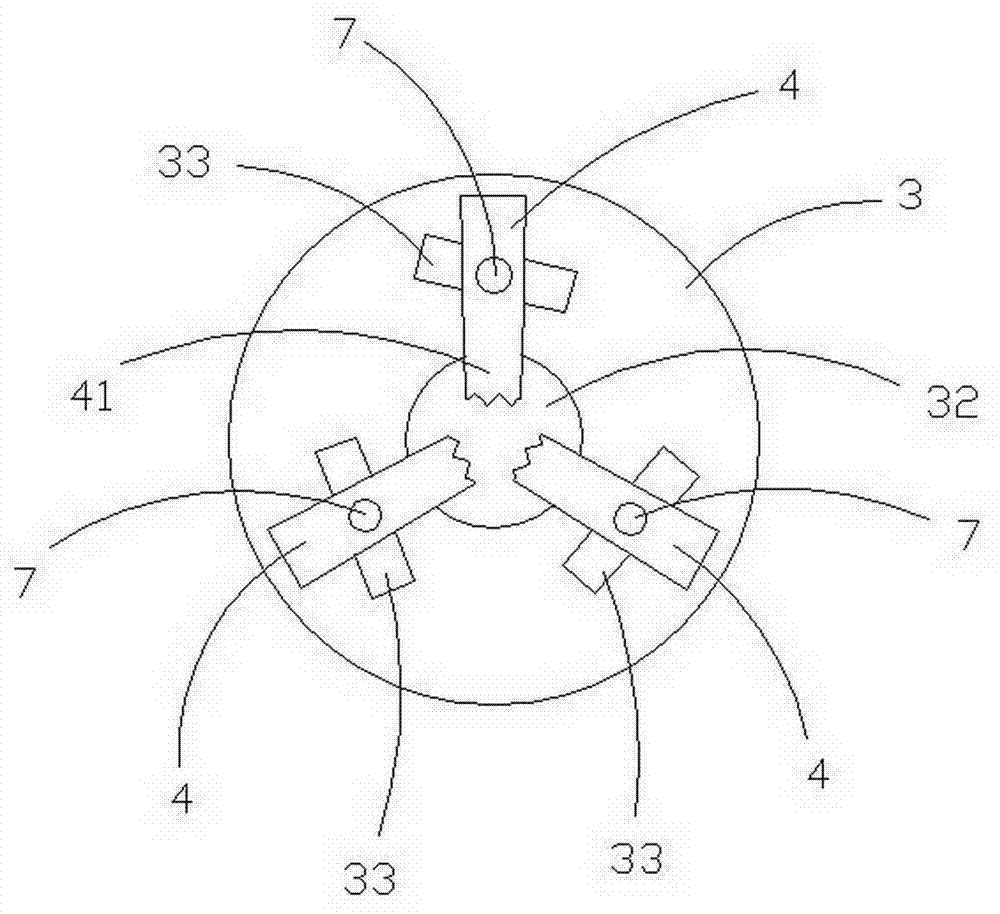

[0015] Such as figure 1 , 2 As shown in , 3, a kind of universal bottle stopper, comprises outer shell 1, is provided with an inwardly recessed bottleneck accommodating groove 11 in the center of the lower end face of outer shell 1, is equipped with punching hole 12 in the through hole 12 of accommodating groove bottom. The air bag 2, the air bag is strip-shaped. The bottle stopper 21 of the air bag 2 stretches out of the housing groove 11, the air pressure portion 22 of the air bag is located in the inner cavity of the outer casing 1, and the air flow control parts 5 are arranged on both sides of the air pressure portion 22 of the air bag, and the drive plate 3 The central hole 32 is sleeved on the outer wall of the inwardly protruding accommodation groove 11, the airflow control part 5 is located above the driving disk 3, the clamping part 52 of the airflow control part is interlocked in the slot of the driving disk 3, and the positioning guide pin I6 The airflow control p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com