Steel plate bin for preventing moisture condensation and mildewing of grains

A steel silo and grain technology, which is applied in the field of steel silos, can solve problems such as grain mildew and affect storage effects, and achieve the effects of preventing grain condensation, ensuring normal use, and ensuring grain storage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

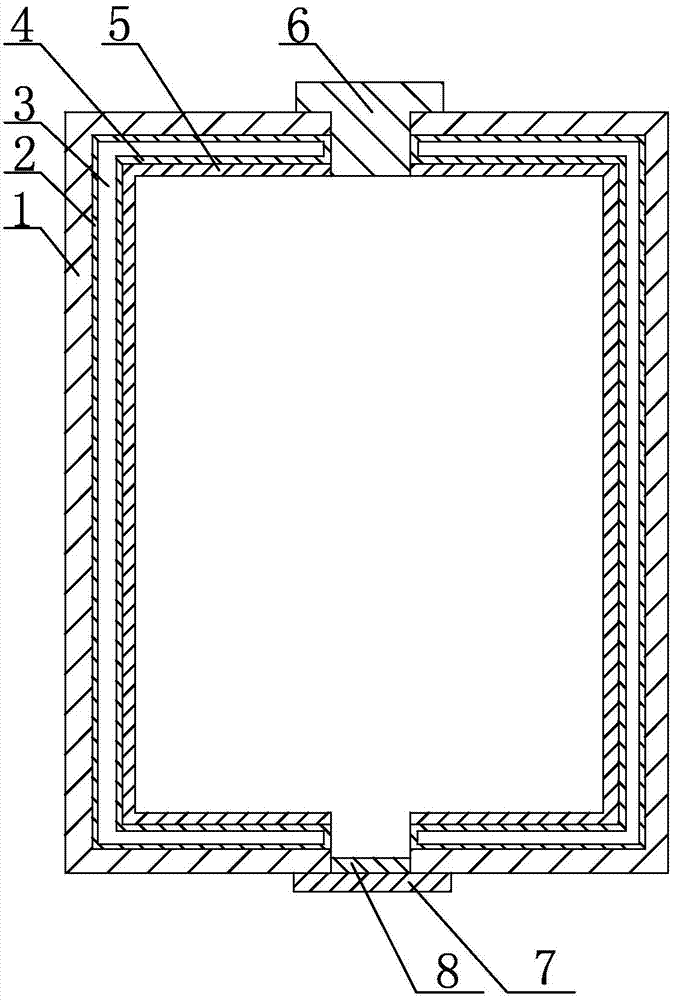

[0012] Such as figure 1 As shown, the steel silo for preventing dew and mold of grain includes a silo body, a feeding port and a discharging port. The outer wall of the silo is successively provided with hot-dip galvanized sheet layer 1, tempered glass layer 1, and tempered glass layer 2 from the outside to the inside. 4 and protective layer 5, a cavity 3 is formed between the tempered glass layer 2 and the tempered glass layer 42. The cavity 3 is vacuumed. A seal 6 is set at the inlet and a discharge plate 7 is set at the outlet. , A sealing block 8 is arranged inside the discharge plate 7, and the sealing block 8 is clamped into the discharge port.

[0013] Among them, the sealing element 6 adopts an elastic rubber material, and the sealing block 8 adopts an elastic rubber block, and the sealing effect is ensured by the elastic material.

[0014] In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com