Mining-use hinged roller-column-type trough-type carrier roller

A technology of rollers and hinges, applied in the direction of rollers, conveyors, conveyor objects, etc., can solve the problems of sparks in safe production, poor waterproof and anti-dust effects, and restrictions on new structures, so as to achieve low manufacturing costs and maintenance costs. Easy installation and disassembly, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in combination with specific embodiments.

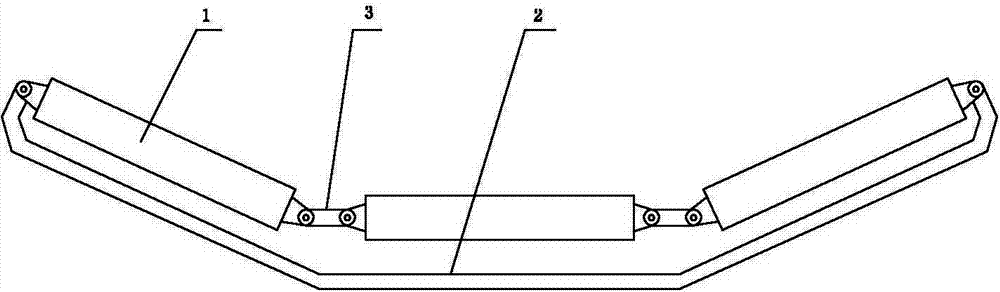

[0017] The invention relates to a articulated roller trough idler for mines, which is provided with a support 2 and three series-connected rollers 1 fixed on the support 2, arranged in a groove shape with high ends and low middle, and two rollers 1 room is hinged by the hinge plate at the end. The support 2 is composed of a bottom plate and two roller fixing seats, and the bottom plate is bent into three flat plates, which are respectively parallel to the upper roller 1 . The outer ends of the rollers 1 at both ends are fixed on the roller fixing seats, and the roller fixing seats are perpendicular to the rollers 1 at both ends.

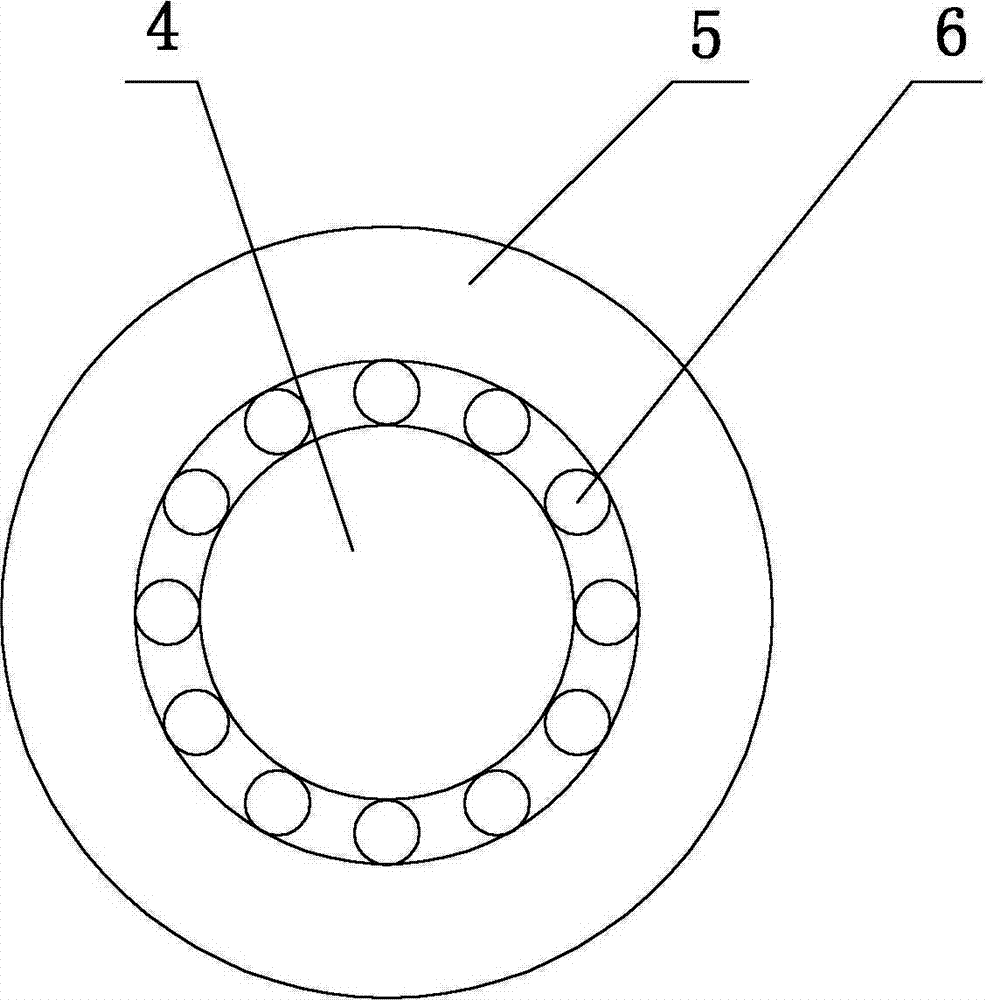

[0018] The center of the roller 1 is a central shaft 4 , the central shaft 4 is covered with a roller outer cylinder 5 , and a bearing 6 is arranged between the central shaft 4 and the roller outer cylinder 5 . The roller outer cylinder 5 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com