Reinforced concrete arch bridge construction method combined with cast-in-place cantilever method and stiff skeleton method

A technology of reinforced concrete and stiff skeleton, which is applied to the erection/assembly of bridges, bridges, buildings, etc., and can solve problems such as difficult realization, limited arch bridge span, and complicated construction technology of stiff skeleton method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] The construction method of the reinforced concrete arch bridge combining cantilever pouring and stiff skeleton comprises the following steps:

[0020] (1) Use the cantilever pouring method to be left-right symmetrical and pour the arch ring segment by segment. The length of the arch ring segment formed by cantilever pouring is 1 / 2-3 / 4 of the total length of the arch ring, and the weight of each segment does not exceed 200 tons. 7-10 days after the previous section is hardened, start pouring the next section; in this embodiment, the lengths of the left and right arch ring sections formed by cantilever pouring are both 1 / 4 of the total length of the arch ring, and the previous section After the segment has hardened for 8 days, pouring of the next segment begins;

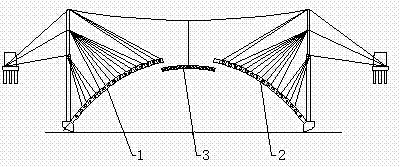

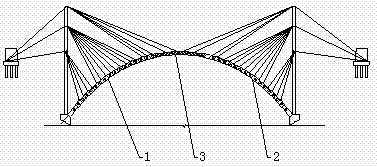

[0021] (2) if figure 1 As shown, after step (1), an arch ring segment with an opening at the top is formed, and a rigid frame is erected at the opening, and the two ends of the rigid frame are respectively conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com