Pinch plate unit and pinch plate installation structure

A technology of gussets and recessed parts, applied in building components, building structures, buildings, etc., can solve problems such as damage to ceilings, failure to match installation, difficulty in dismantling gussets, etc., and achieve low manufacturing cost, beautiful appearance, and elegant appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

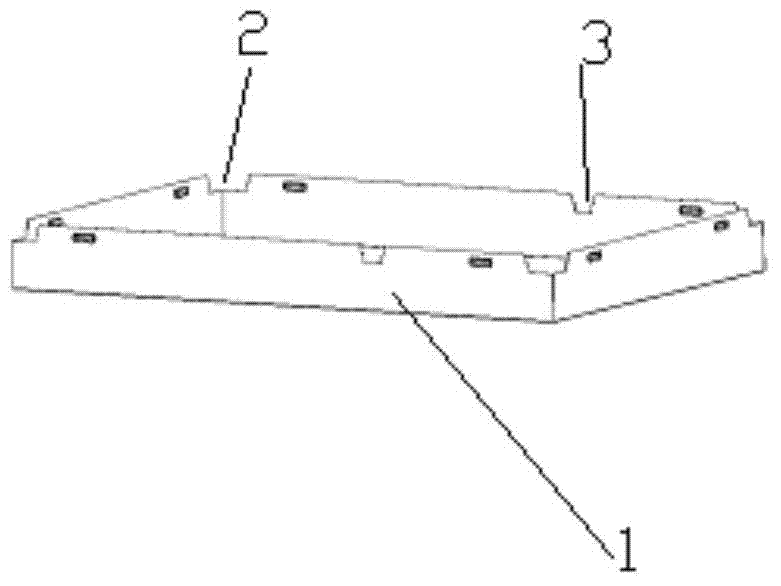

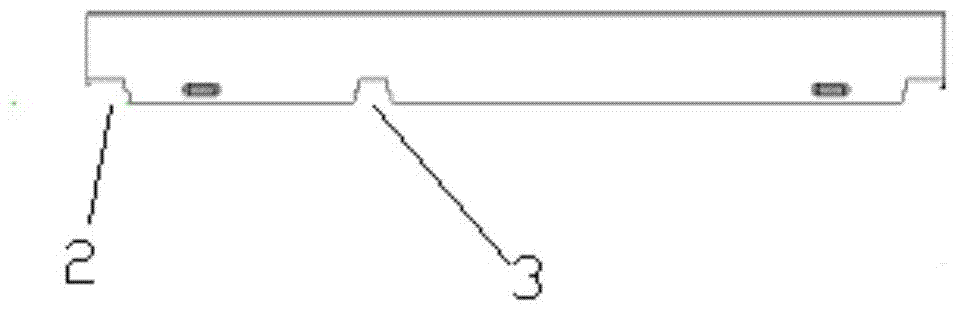

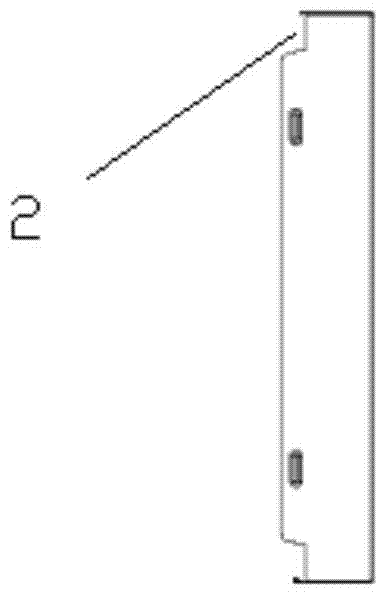

[0023] Figure 1-Figure 3 It is a structural schematic diagram of the gusset unit provided in this preferred embodiment. The gusset unit includes a rectangular gusset body 1 and a recessed part provided on the gusset body 1. The recessed part is used for clamping with the keel, wherein the recessed The part includes a first recessed part 2 arranged at the four corners of the gusset body 1 and at least one second recessed part 3 arranged between the first recessed parts 2, and the second recessed part 3 is arranged on the side of the gusset body 1 Above, the long side of the gusset body 1 is 448cm-452cm, and the short side of the gusset body 1 is 298cm-302cm.

[0024] In this preferred embodiment, the second recessed portion 3 is a trapezoidal groove formed inwardly on the side of the pinch plate body 1 for matching with the keel structure. The second recessed portion 3 includes two, and the two second recessed portions 3 are symmetrically arranged on the two long sides of the...

Embodiment 2

[0027] This preferred embodiment provides a gusset unit, the structure of which is basically the same as that of the preferred embodiment 1. The gusset unit includes a rectangular gusset body and a recessed part provided on the gusset body. The recessed part is used to engage with the keel Then, wherein, the recessed portion includes a first recessed portion arranged at the four corners of the pinch plate body and at least one second recessed portion arranged between the first recessed portions, and the second recessed portion is provided on the side of the pinch plate body , The long side of the gusset body is 448cm~452cm, and the short side of the gusset body is 298cm~302cm.

[0028] The difference is that: the specific shape of the second concave part is not limited, it can be a trapezoidal groove formed by indentation, or a groove of other shapes can be formed, as long as it can meet the requirements of fitting with the keel; the second concave part The specific number is ...

Embodiment 3

[0030] This preferred embodiment discloses a gusset installation structure, such as Figure 4 As shown, the gusset installation structure includes a plurality of keels 4 arranged at equal intervals, and the gusset unit as described in the preferred embodiment 1 or 2 is arranged on the keel 4, and the first recess 2 and the second depression of the gusset unit Both parts 3 are clamped with the keel 4. During installation, the first recessed part 2 and the second recessed part 3 can be clamped in the keel according to the size of the gusset unit to form a complete indoor ceiling structure. The gusset installation structure can It is installed according to the user's individual installation requirements. The overall structure is beautiful and elegant, easy to install and easy to disassemble.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com