A coiled tubing hydraulic two-way jar

A jar and hydraulic technology, applied in wellbore/well parts, earthwork drilling and production, etc., can solve problems such as technical level, product quality and maintenance service gap, no good solution, and influence of processing accuracy, etc., to achieve Easy maintenance, simple structure, strong vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

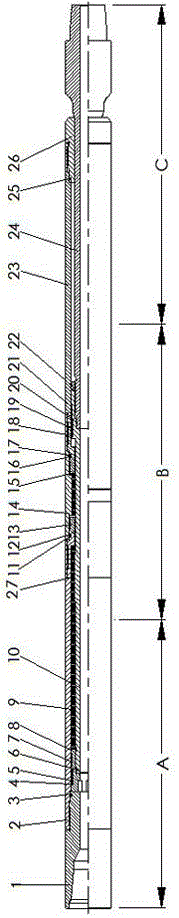

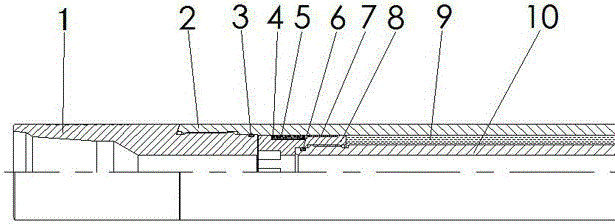

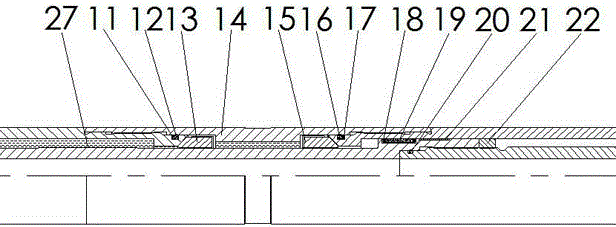

[0023] This embodiment provides a coiled tubing hydraulic two-way jar, such as Figure 1~4 As shown, it includes an outer casing part composed of an upper joint 1, an upper cylinder liner 2, an intermediate joint 14, a lower cylinder liner 23, and a tail sleeve that are threaded in sequence, and an impact tube nut 8, an impact tube 10, and The mandrel part constituted by the lower joint 24 is slidably connected with the inner cavity of the jacket part, and the two can move relatively axially. The impact tube 10 is a variable-diameter tube with a smooth transition in which the diameter of the middle part is larger than that of both ends, and its outer annular space is filled with hydraulic oil 9; the lower end of the upper cylinder liner 2 and the upper end of the lower cylinder liner 23 are both outer Both ends of the intermediate joint 14 are internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com