Elastic penetrating part for high temperature pipeline

A technology of piercing parts and high temperature pipes, applied in the direction of pipes/pipe joints/pipe fittings, pipes, mechanical equipment, etc., can solve the problems of high temperature pipeline penetration and vibration isolation, and achieve compact overall structure, convenient installation and disassembly, and good reliability. Effects of Sex and Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

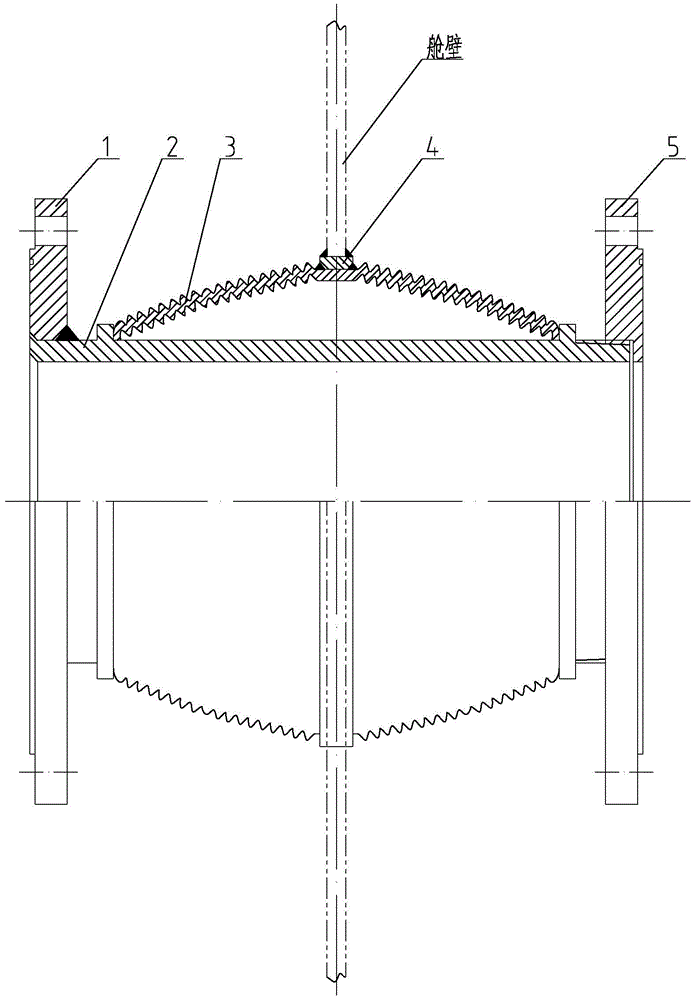

[0018] as attached figure 1 As shown, the present invention provides an elastic penetration for high-temperature pipelines, an elastic penetration for high-temperature pipelines, including a welding flange 1, an inner pipe 2, a metal bellows 3, a welding ring 4 and a screw thread method Lan 5;

[0019] The outer peripheral surface of the inner tube 2 is provided with two radial limiting bosses, and the outer peripheral surface of one end is processed with a threaded section, the threaded section starts from the end surface of the inner tube 2 and ends at the end of the limiting boss. step surface;

[0020] The shape of the metal bellows 3 is a spindle-shaped structure, and the inner and outer circumferential surfaces of the largest diameter are planar structures;

[0021] The overall connection relationship is as follows: the two ends of the metal bello...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com