Touch control board

A touch panel and substrate technology, which is applied in the fields of instruments, electrical digital data processing, and data processing input/output processes, etc., can solve the problems of unfavorable design trends in the surrounding area 142, and achieve the reduction of the area size, the realization of design, and the realization of narrower The effect of the border

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

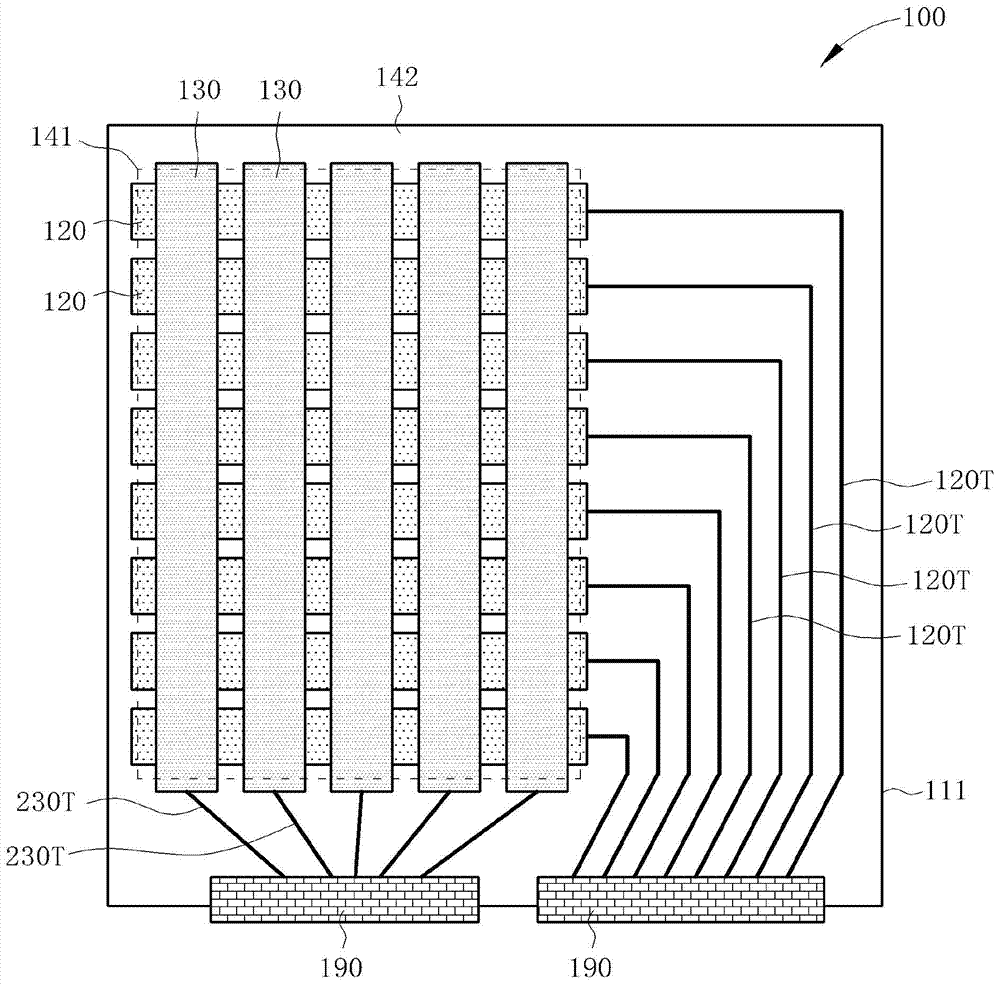

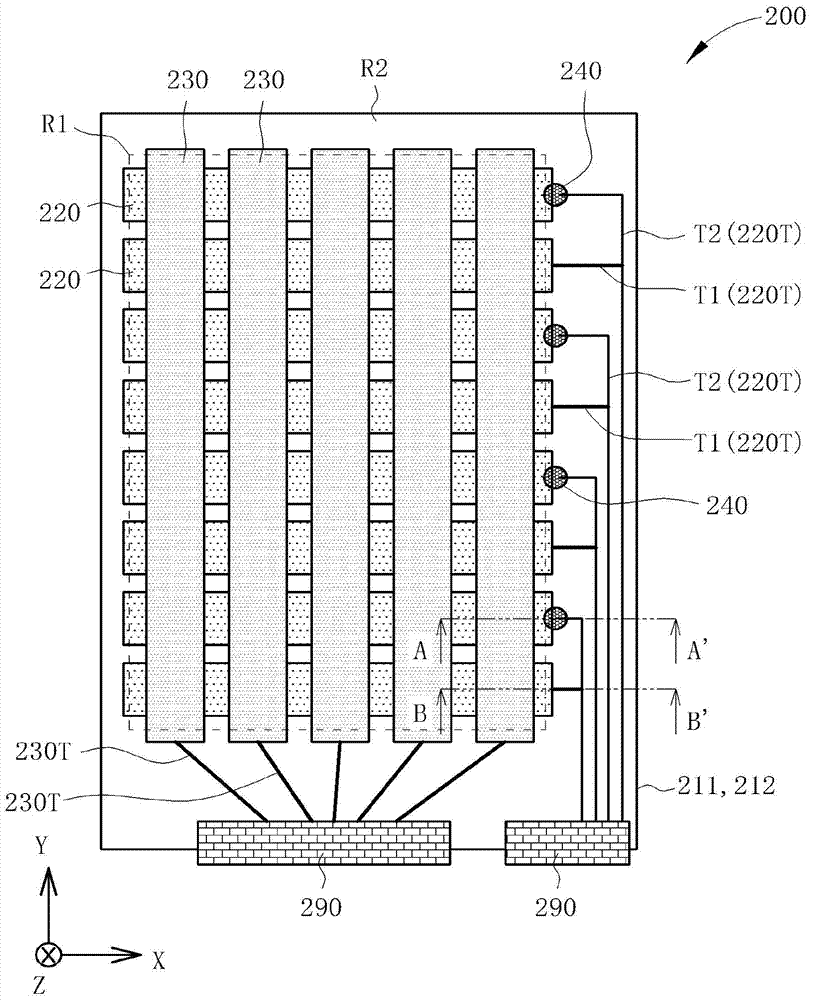

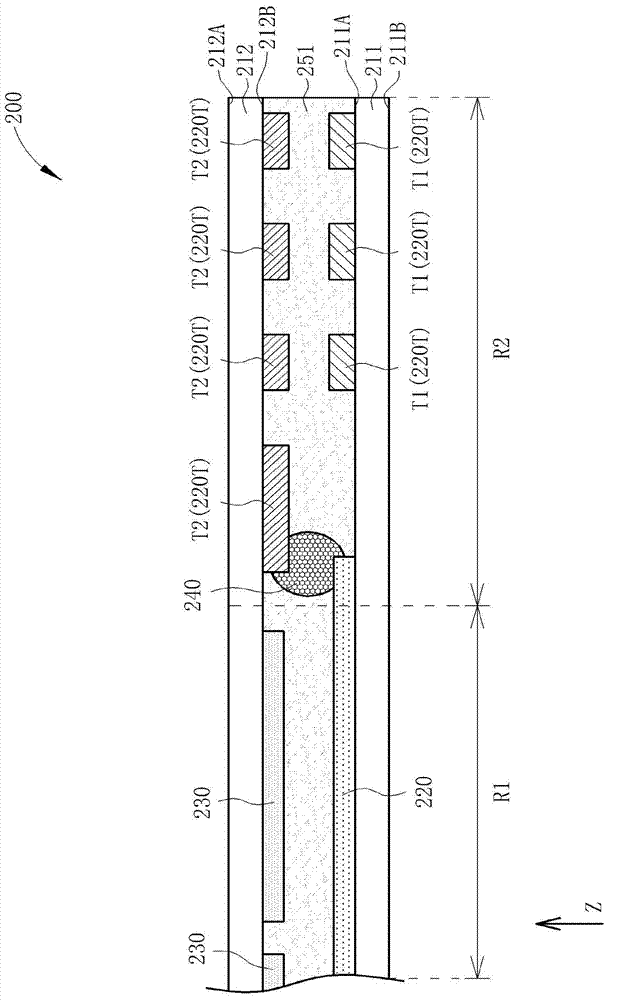

[0063] Such as Figure 2 to Figure 4 As shown, the touch panel 200 according to Embodiment 1 of the present invention has a light-transmitting region R1 and a surrounding region R2. The surrounding area R2 is located on at least one side of the transparent area R1. In this embodiment, the surrounding area R2 preferably surrounds the transparent area R1, but it is not limited thereto. The touch panel 200 includes a first base 211 , a second base 212 , a plurality of first electrodes 220 , at least one first trace T1 , at least one second trace T2 and at least one conductive structure 240 . The first base 211 has a first surface 211A and a second surface 211B, and the first surface 211A is opposite to the second surface 211B. The second base 212 is opposite to the first base 211 . The second substrate 212 has a third surface 212A and a fourth surface 212B, the fourth surface 212B is opposite to the third surface 212A, and the first surface 211A of the first substrate 211 face...

Embodiment 2

[0068] Such as Figure 5 As shown, the touch panel 300 according to Embodiment 2 of the present invention may further include a decoration layer 260 disposed between the first substrate 211 and the second substrate 212 and located in the surrounding area R2. In this embodiment, the decoration layer 260 is preferably disposed on the fourth surface 212B of the second substrate 212 and located between the second trace T2 and the second substrate 212 , but it is not limited thereto. In addition, the second substrate 212 of this embodiment is preferably a cover plate such as cover glass or cover plastic. The cover plate can be a light-transmitting substrate strengthened by chemical or physical methods, such as strengthened glass after chemical ion exchange or heat treatment, which has high mechanical strength, anti-fouling, anti-scratch and other characteristics, and can protect adjacent touch components Or a monitor. The decoration layer 260 can be used to form an appearance dec...

Embodiment 3

[0070] Such as Figure 6 to Figure 8 As shown, the difference between the touch panel 400 of the third embodiment of the present invention and the first embodiment above is that the first trace T1 and the second trace T1 respectively arranged on the first substrate 211 and the second substrate 212 in this embodiment The wires T2 are preferably arranged to be offset from each other, so as to reduce signal interference between each other. In this embodiment, there is a space area S between two adjacent first traces T1, and at least one second trace T2 and the corresponding space area S at least partially overlap each other in the vertical projection direction Z, for The overlapping area of the first trace T1 and the second trace T2 in the vertical projection direction Z is reduced, thereby reducing the signal interference between the first trace T1 and the second trace T2. Specifically, the center point of the at least one second trace T2 in the first direction X preferably o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com