Analog cabin boost gauge

A cabin and instrument technology, applied in simulators, simulation devices and instruments of space navigation conditions, etc., can solve the problems of weak sense of reality, inability to perceive instrument devices, and inability to achieve training effects, and achieve the improvement of realism. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The patent of the present invention will be further described in detail below in conjunction with specific embodiments.

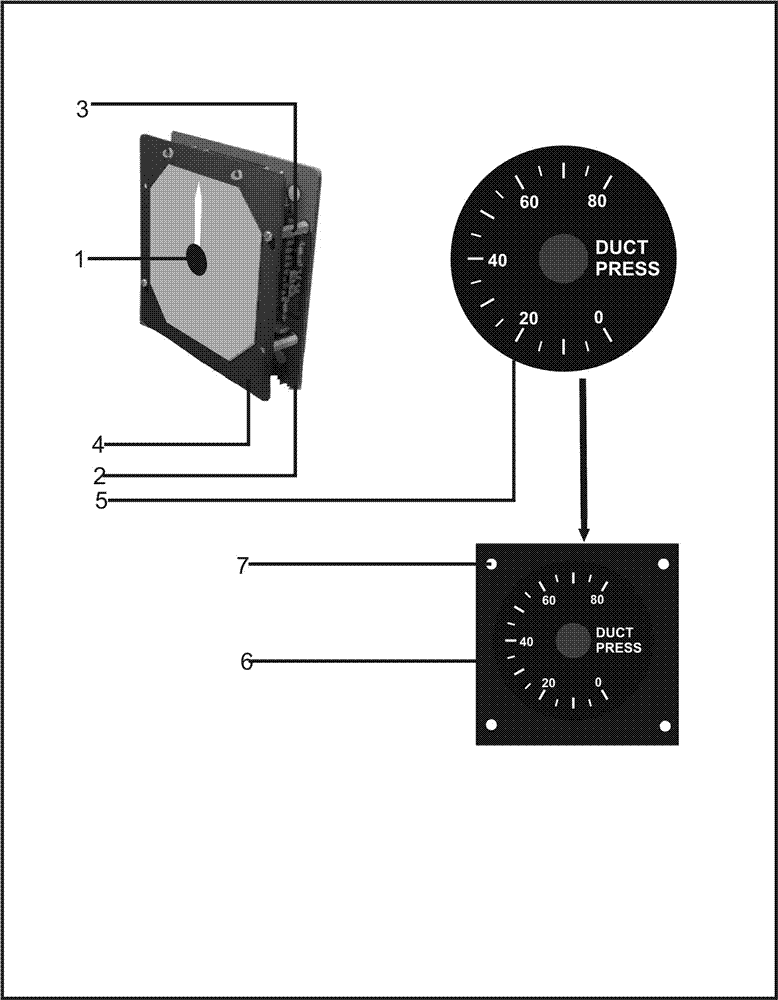

[0009] Such as figure 1 As shown, the structural principle diagram of the simulated cabin pressurization meter of the patent of the present invention; the simulated cabin pressurization meter includes a servo control circuit board, a cabin pressurization pointer, a cabin pressurization scale surface sticker, a cabin pressurization scale panel, and a cabin pressurization front panel ; It is characterized in that: under the control of the servo control circuit board, the cabin pressurization pointer moves to the position indicated by the cabin pressurization scale sticker. The control circuit board 2 of the cabin pressurization server is equipped with a screw column 3 for fixing the cabin pressurization scale panel 4, the cabin pressurization pointer 1 is installed in the middle of the cabin pressurization scale panel 4, and the cabin pressurization sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com