A kind of automatic control socket specially used for electric kettle

A technology for electric kettles and sockets, which is applied to circuits, discharge lamps, discharge tubes, etc., and can solve the problems affecting the reliability of the conductivity of the large conductive ring conductive sheet and the large conductive ring, the large conductive ring conductive sheet and the large conductive ring are easy to wear, Poor contact and other problems, to achieve the effect of strong elasticity, increased thrust, and increased conductive reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

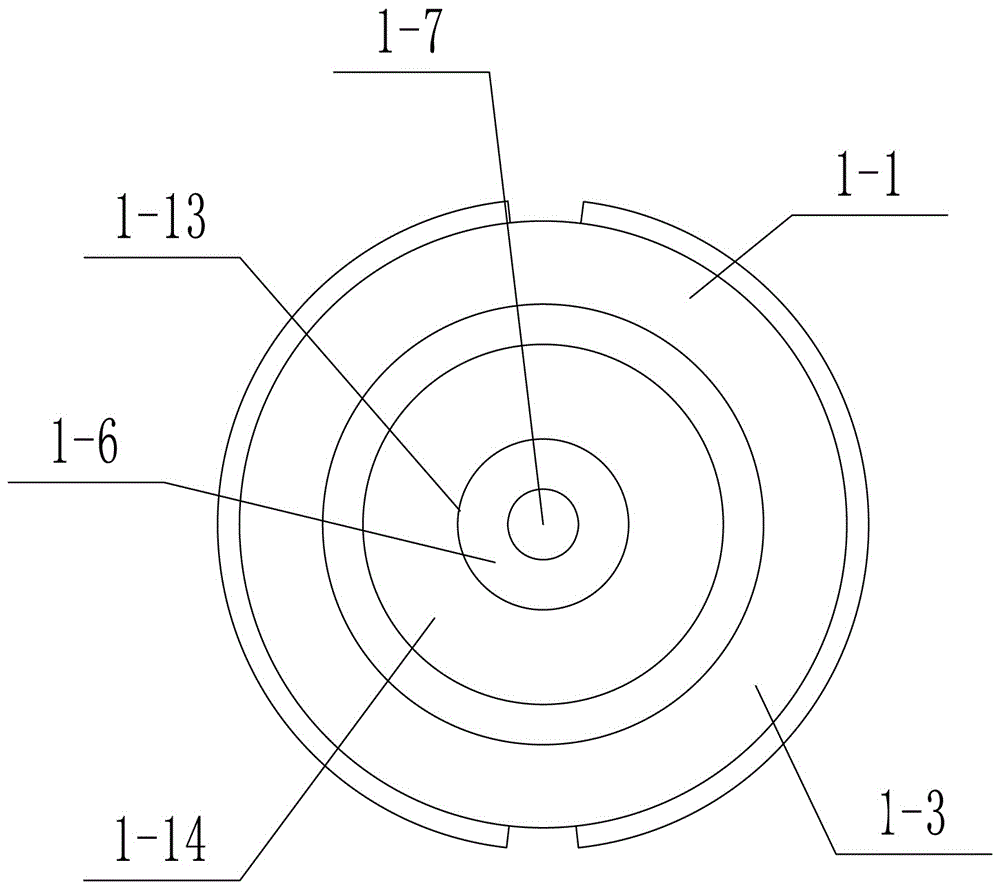

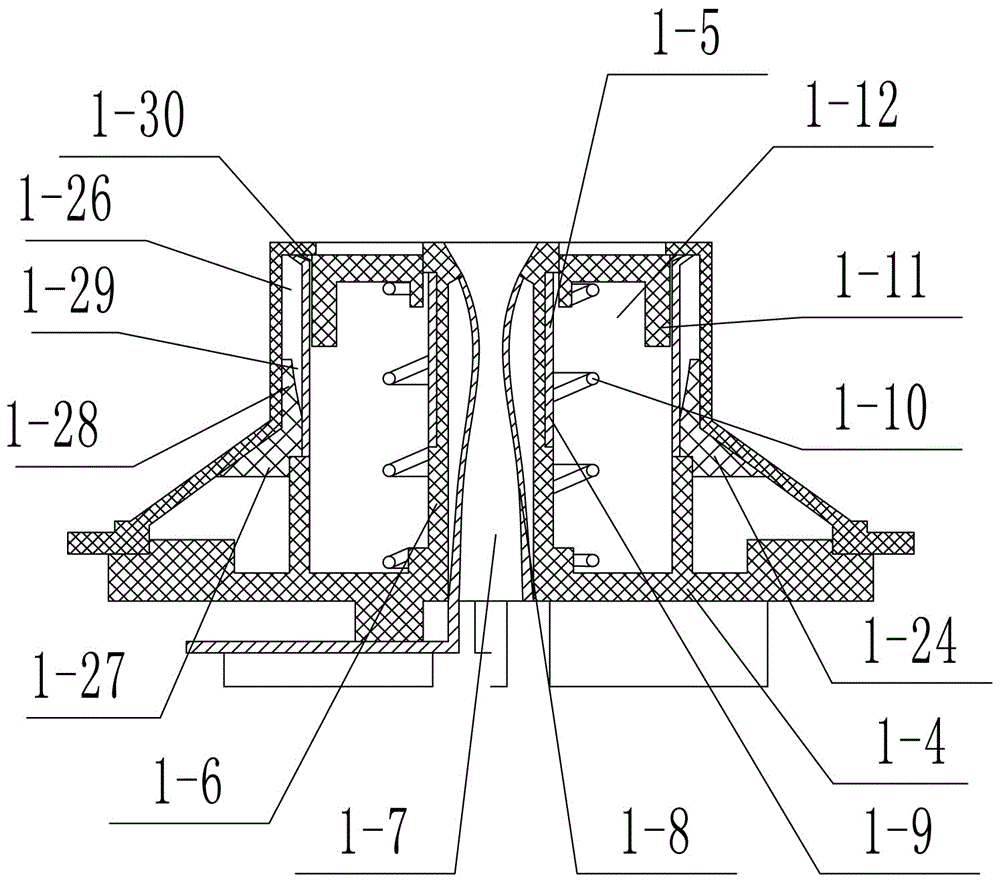

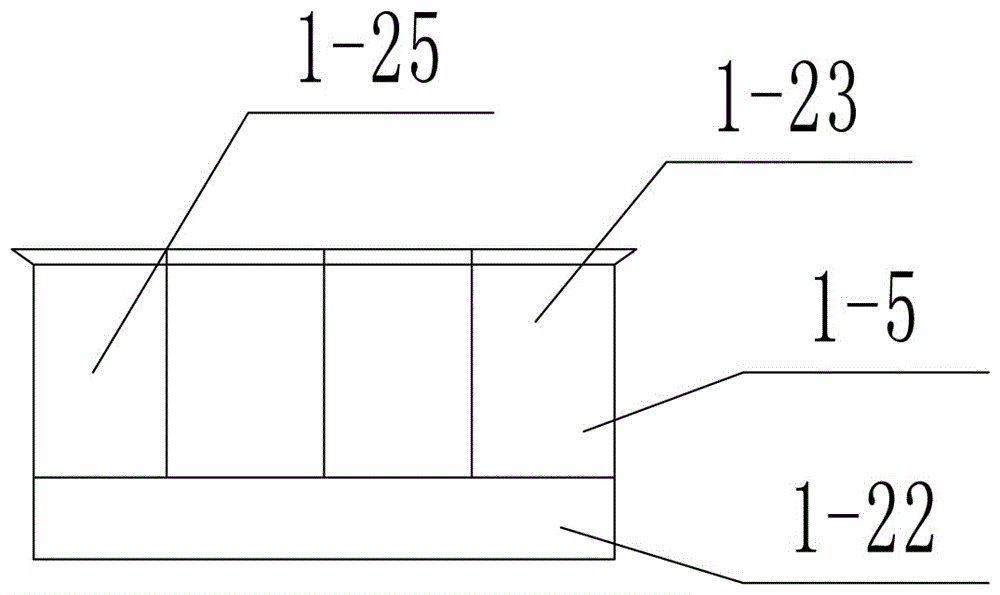

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the embodiment of an automatic control socket dedicated to electric kettles provided by the present invention includes a matched lower seat 1-1 and an upper seat 1-2, and the lower seat 1-1 includes a shell 1-3 and a base 1-4, the base 1-4 is provided with a large conductive ring 1-5 and a cylindrical column 1-6, the cylindrical column 1-6 has a grounding jack 1-7, and the grounding jack 1- 7 is provided with a grounding spring 1-8, a small conductive ring 1-9 is provided on the outer surface of the cylindrical column 1-6, and a compression spring 1-10 is set on the cylindrical column 1-6. The lower end of the compression spring 1-10 abuts against the base 1-4, the upper end of the compression spring 1-10 is provided with a protective cover 1-11, and the small conductive ring 1-9 is located between the compression spring 1-10 and the cylinder. Between the cylindrical column 1-6, the cylindrical column 1-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com