Case with filtering function

A chassis and function technology, applied in the fields of dispersed particle filtration, chassis/cabinet/drawer parts, dispersed particle separation, etc., can solve the problems of high labor maintenance cost, low replacement efficiency, frequent filter replacement, etc. The effect of reducing manual maintenance and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

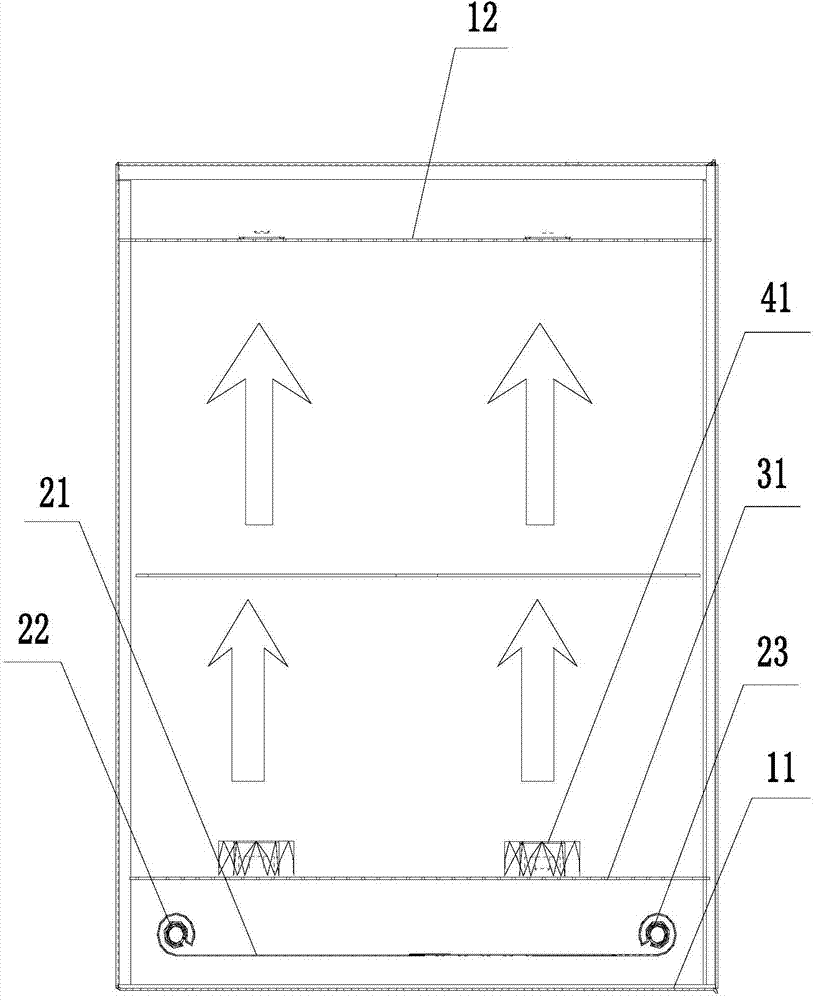

[0039] figure 1 Schematically provides a simplified structural diagram of a cabinet with a filtering function in an embodiment of the present invention, as figure 1 As shown, the chassis includes:

[0040] Air inlet 11, exhaust port 12, described air inlet, exhaust port are arranged on the chassis;

[0041] The filter screen 21, the filter screen is arranged at the inlet air, and the two ends are respectively wound on the first rotating shaft and the second rotating shaft; when the first rotating shaft rotates, the used filter screen is wound on the first rotating shaft, The unused filter screen is placed in the air intake channel to filter particles, insects, etc. in the air, so as to ensure that the air entering the chassis is clean;

[0042] A replacement device, the replacement device includes a first rotating shaft 22, a second rotating shaft 23 and a motor, and the first rotating shaft and the second rotating shaft are fixed on the cabinet wall;

[0043] Fan 41, said ...

Embodiment 2

[0050] An application example of the cabinet according to Embodiment 1 of the present invention in a communication cabinet.

[0051] In this application example, if figure 1 As shown, the motor drives the first rotating shaft to rotate, and the working time and interval time of the motor are controlled by the timer. Both the air inlet 11 and the exhaust port 12 are provided with a mesh plate, and a mesh plate 31 is arranged downstream of the filter screen 21 , and the fan 41 is arranged on the mesh plate 31 . The entire filter is 9 meters long, 0.6 meters each time it is used, and it is replaced every 4 months, which can guarantee that there is no need to replace the filter manually for about 5 years.

[0052] When the above-mentioned cabinets are working normally, there is a 0.6m*0.6m dust-proof filter at the air inlet of the cabinet to play the role of dust-proof filter. On the other hand, it plays the role of recycling the dust-proof net. After the dust-proof filter scre...

Embodiment 3

[0054] A schematic structural diagram of a cabinet with a filtering function in an embodiment of the present invention, the cabinet includes:

[0055] an air inlet and an exhaust port, the air inlet and the exhaust port are arranged on the chassis;

[0056] Filtration unit, described filtration unit comprises:

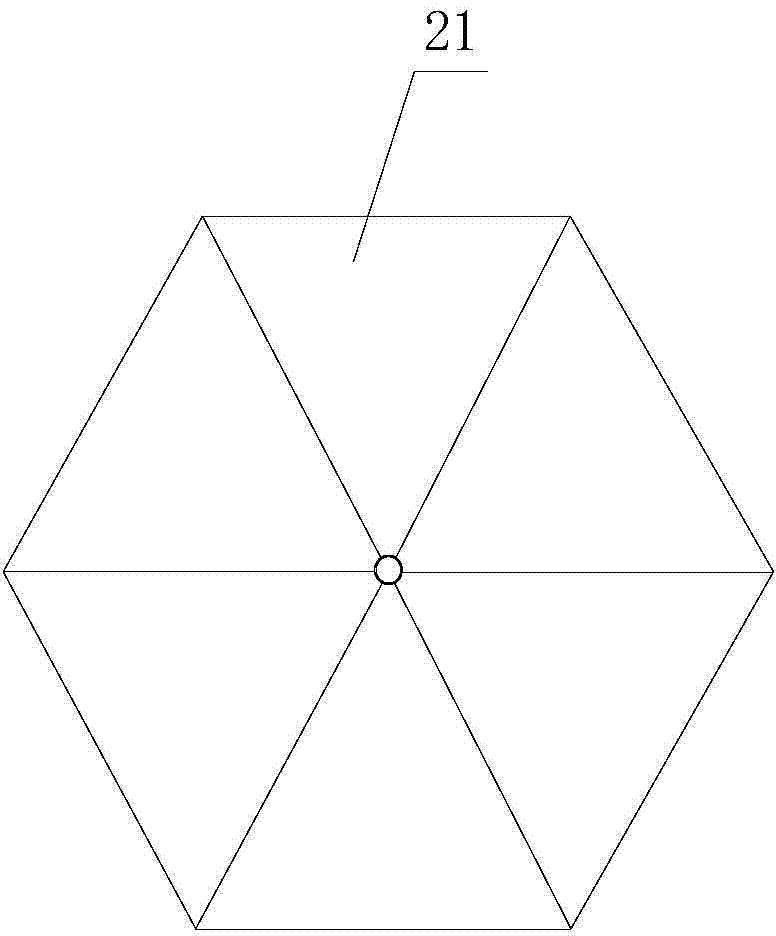

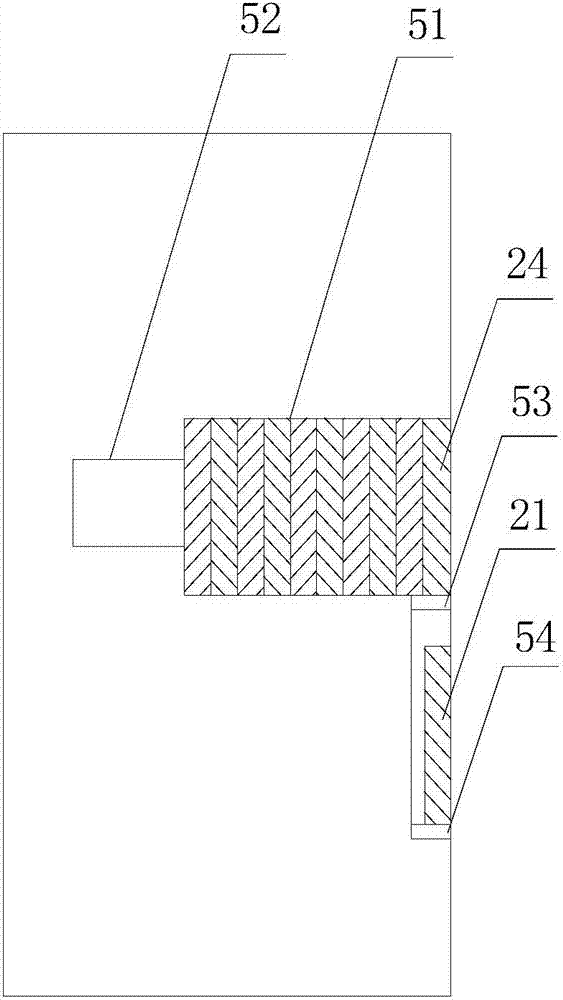

[0057] filter, such as figure 2 As shown, there are 6 filter screens 21 in a triangular shape, all of which are arranged on the filter unit, and the filter unit is installed on a rotating shaft for rotation, and the rotating shaft is arranged at the side of the air inlet. When the filter unit rotates, the 6 filter screens are placed at the air inlet in time-sharing to filter particles, insects, etc. in the air, so as to ensure the cleanliness of the air entering the chassis;

[0058] The replacement device includes a motor, and the motor is used to drive the filter unit to rotate; the driving method is such as gear transmission or belt transmission;

[0059] A contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com