Water cooling device

A water-cooling device and water-cooling jacket technology, which is applied in the field of heating furnaces, can solve the problems of shortening the life of the oil-cooling jacket sealing ring, complicated structure of the oil-cooling device, affecting the service life of bearings, etc., so as to achieve high production costs, save time and labor costs, and improve The effect of equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following will be described in detail in conjunction with the accompanying drawings and embodiments.

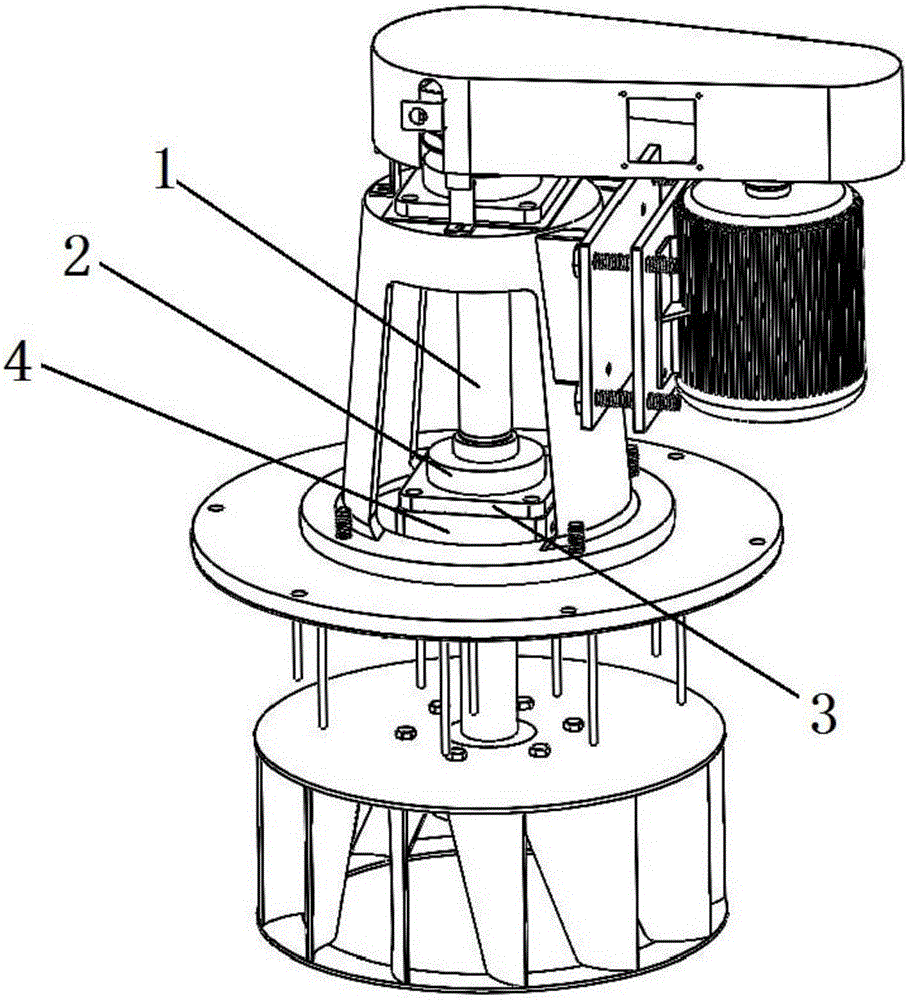

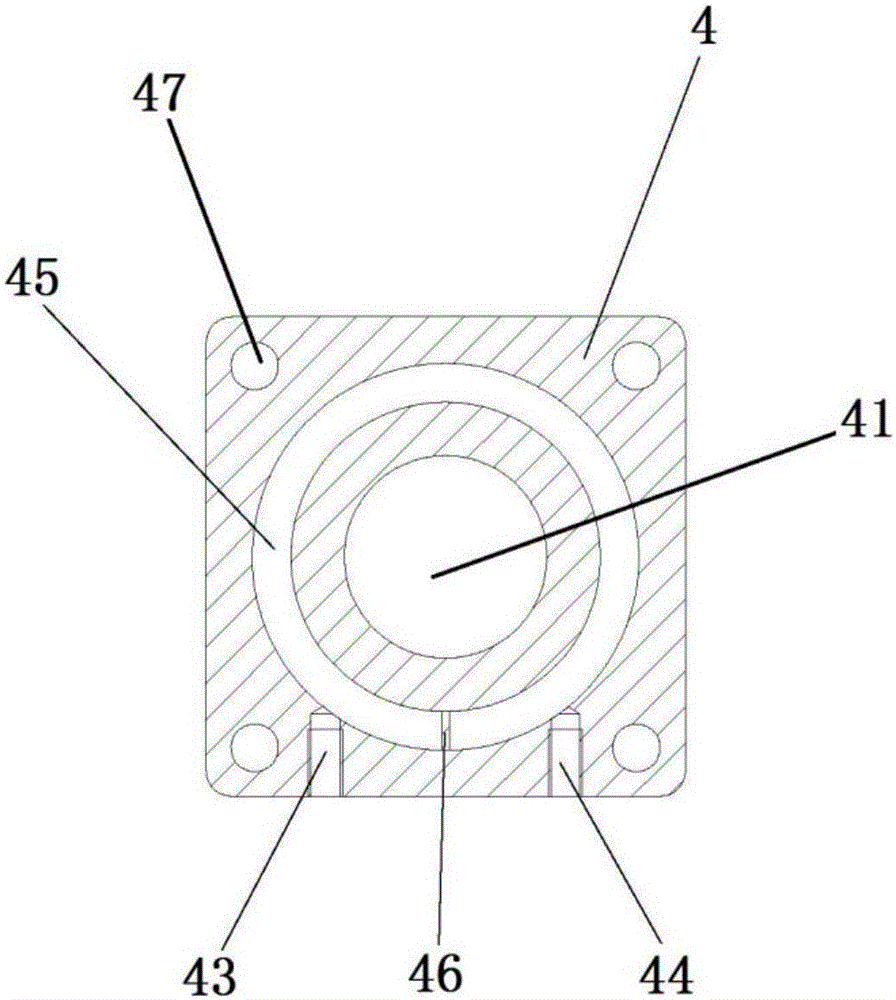

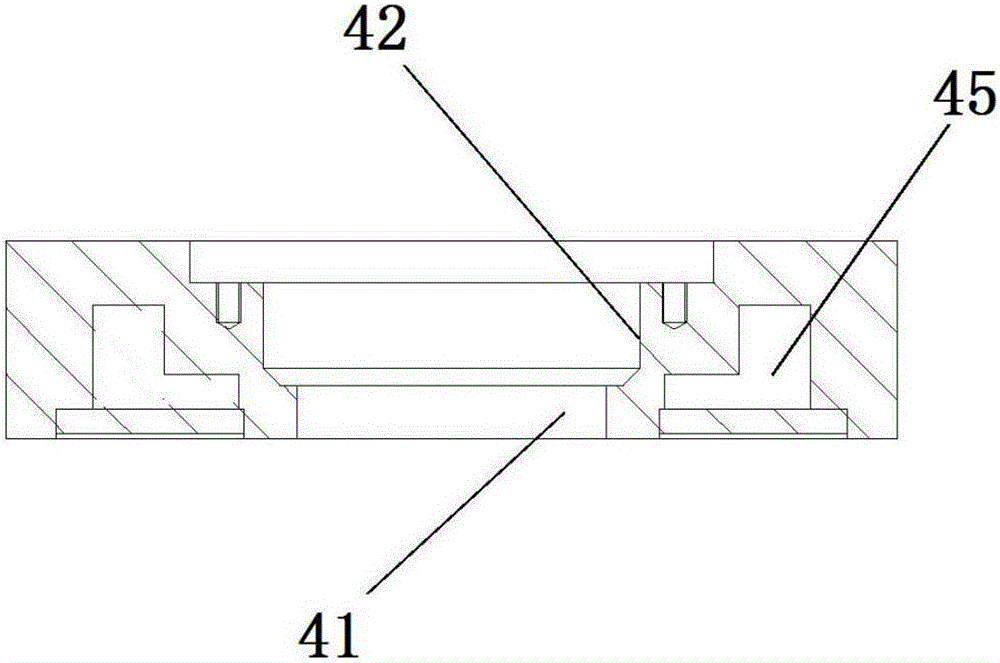

[0018] refer to Figure 1 to Figure 3 , The water cooling device of the present invention includes a stirring shaft 1 , a stirring bearing 2 sleeved on the stirring shaft 1 , a bearing seat 3 , and a water cooling jacket 4 . The water cooling jacket 4 is arranged below the bearing seat 3 , and the center of the water cooling jacket 4 is provided with a circular connection hole 41 , and a sealing step 42 is provided above the connection hole 41 , and the water cooling jacket 4 is sleeved on the stirring shaft 1 through the connection hole 41 . A water inlet 43 and a water outlet 44 are arranged on the side wall of the water cooling jacket 4 , and the water inlet 43 and the water outlet 44 are arranged on the same side of the water cooling jacket 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com