Novel waste vehicle

A new type of technology for waste carts, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of waste cart rollers derailed, rack deformation, rollover, etc., to improve production efficiency, stable and reliable reception, and reduce labor The effect of time to maintain and adjust the wheel and track mate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The above is only an overview of the technical solution of the present invention. In order to better understand the technical means of the present invention and implement it according to the contents of the description, the technical solution of the present invention will be further described below with a preferred embodiment and accompanying drawings.

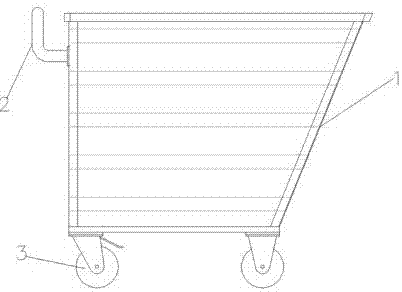

[0011] A new type of waste vehicle, the new type of waste vehicle includes a vehicle body 1, a handlebar 2, and wheels 3, one side of the vehicle body 1 is provided with a handlebar 2 that is rotatably connected to the vehicle body 1, the The bottom of the car body 1 is provided with several wheels 3. The car body 1 is composed of 4 pickling plates and forms a cavity. The pickling plates are hot-rolled thin plates. The handlebar is made of iron nickel chromium, Composed of iron-nickel-manganese and manganese-nickel-copper alloy, the iron-nickel-chromium accounts for 34%-40% of the overall weight of the handlebar, the iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com