Automatic air locking dehydration device for gas pipeline

A gas pipeline and dehydration device technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of scattered installation sites, wide distribution range, large investment, etc., and achieve reduced labor intensity and less manual maintenance , the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

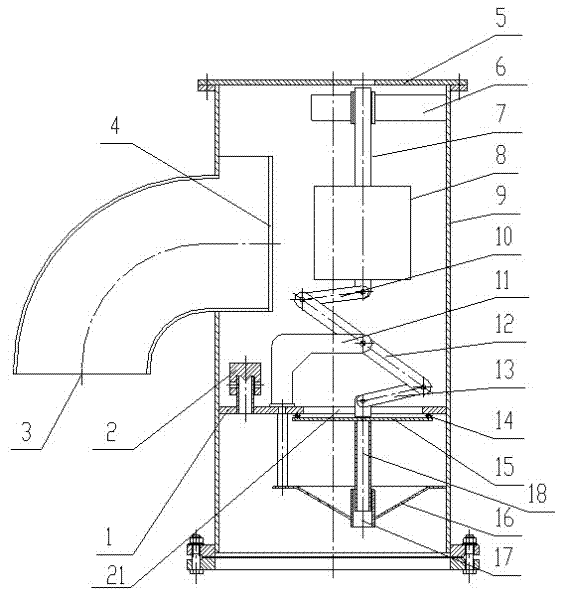

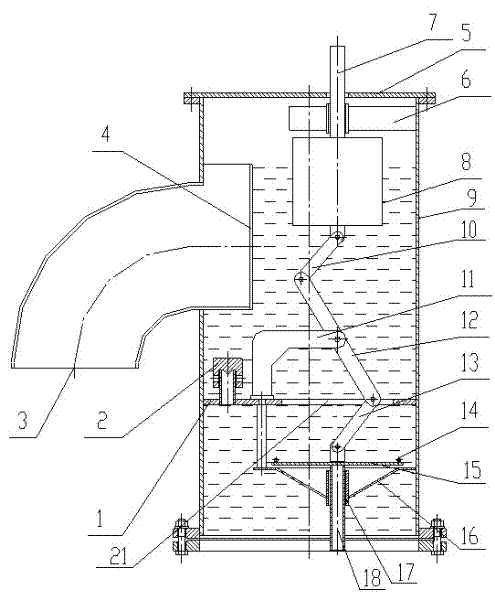

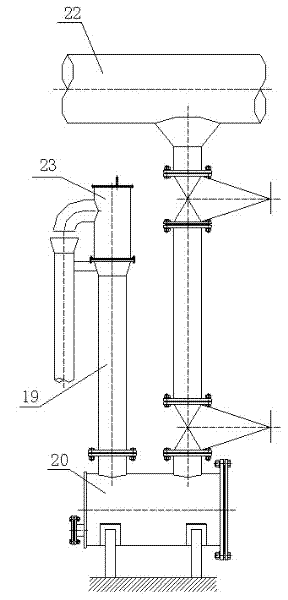

[0017] like figure 1 and 2 As shown, the gas pipeline automatic gas lock dehydration device of the present invention comprises an outer shell 9, the top of the outer shell 9 is provided with a dustproof cover 5, and the side of the outer shell 9 is provided with an overflow port 3, and the overflow port 3 is connected to the outer shell The water tank 4 in 9 is connected, the setting of the water tank 4 has improved the effective water seal height of the gas drainer 20, increased the water seal safety margin of the gas drainer 20, and the outer shell 9 inner wall below the dust cover 5 is equipped with Guide frame 6, the guide frame 6 is provided with a water level display rod 7 that runs through the outside of the dust cover 5, and the water level display rod 7 can intuitively reflect the water level in the gas drainer 20. The lower end of the water level display rod 7 and the buoy 8 The connection is fixed, the bottom of the buoy 8 is hinged to one end of the connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com