Adaptive sheetmaking machine control system

一种控制系统、片材的技术,应用在造纸机、造纸、纺织品和造纸等方向,能够解决时间和材料损失等问题,达到减少废料和损失时间、消除湿端干扰、消除控制延迟的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

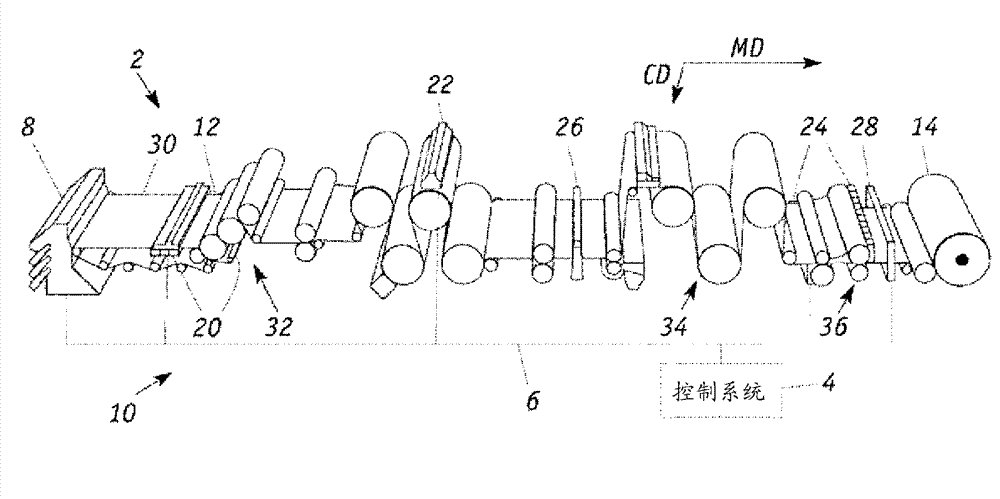

[0018] A process control system will be illustrated by implementing the technique in a sheet manufacturing system 10 comprising a paper machine 2, a control system 4 and a network 6 such as figure 1 shown in . The paper machine 2 produces a continuous sheet material 12 which is collected by a take-up reel 14 . The sheet material 12 is of a specified width and is produced from a stock suspension comprising an aqueous mixture of wood fibers and other materials which undergoes various unit operations which are monitored and controlled by the control system 4 . Network 6 facilitates communication between components of system 10 .

[0019] The paper machine 2 includes a headbox 8 which distributes the stock suspension evenly across the machine on a continuously moving screen or wire 30 . The stock suspension entering the headbox 8 may contain eg 0.2-3% wood fibers and possibly other solids, the remainder of the suspension being water. The headbox 8 comprises any suitable structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com