Bathroom placing rack assembling mechanism and bathroom placing rack with same

A placing rack and assembling technology, which is applied in the field of bathroom placing racks, can solve the problems of inconvenient maintenance or repair, easy deflection, and difficult assembly, etc., and achieves the effects of convenient maintenance or repair, easy disassembly and assembly, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples illustrate possible implementations of the present invention, but are not intended to limit the protection scope of the present invention.

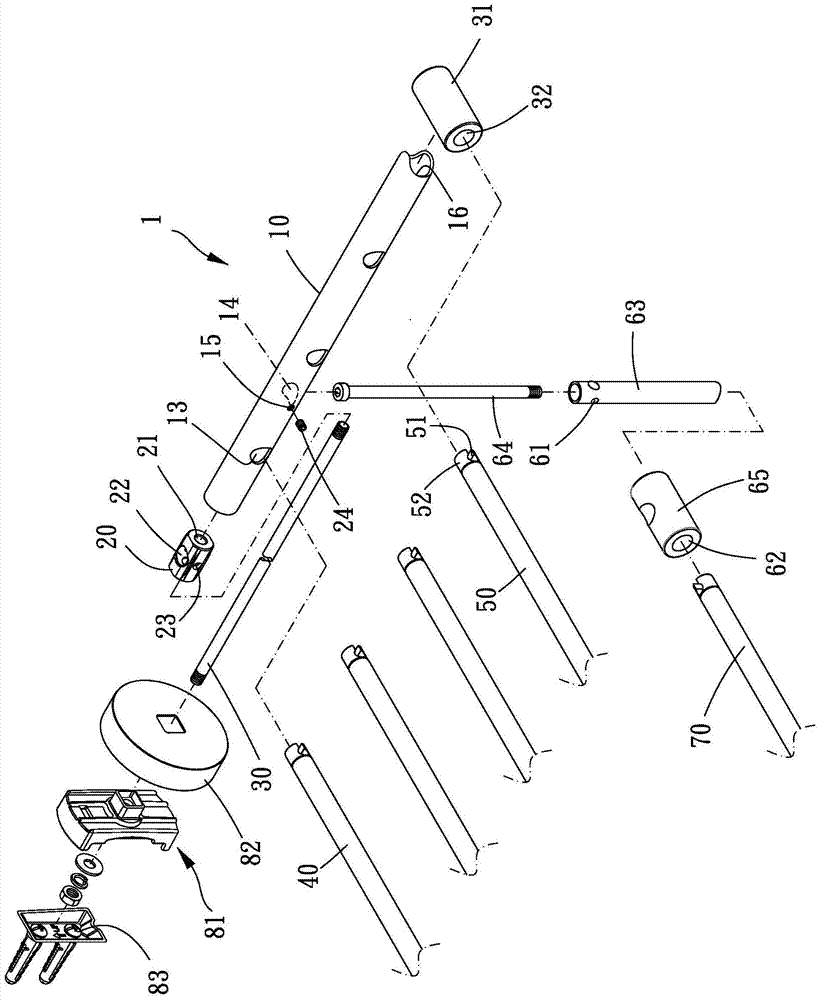

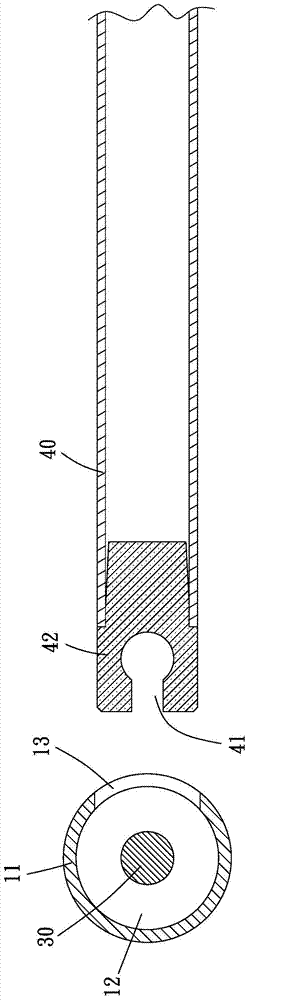

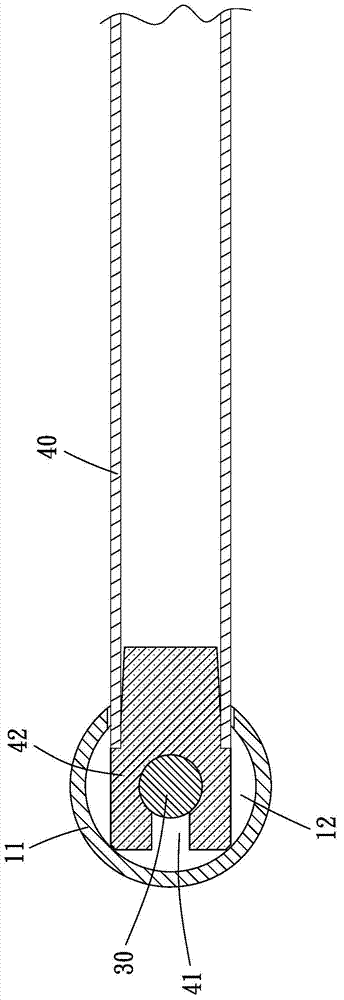

[0024] Please refer to Figure 1-4 , which shows the first preferred embodiment of the present invention, the bathroom rack assembly mechanism 1 of the present invention includes a pipe 10 , at least one insert 20 , a first rod 30 and at least a first connecting rod 40 .

[0025] The pipe member 10 has a pipe wall 11 and an inner pipe 12 extending between opposite first and second ends of the pipe member 10 . The pipe wall 11 defines at least one first through hole 13 . In detail, the pipe wall 11 is provided with a plurality of first through holes 13 arranged at intervals, and the pipe wall 11 of the pipe member 10 is also provided with at least one first through hole 13 whose opening direction is different from the opening direction of the at least one first through hole 13 . Two through holes 14, and a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com